Ball Mill

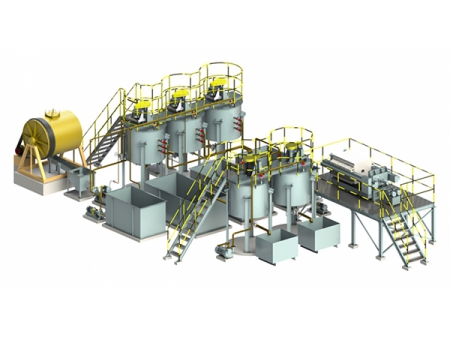

The ball grinding mill is a key piece of equipment utilized for grinding crushed materials. A ball grinding mill consists of a hollow cylindrical shell which is partially filled with balls. The grinding media is the steel balls which can be used for reducing the size of materials to a fine powder. Grinding can be carried out either wet or dry for various ores and other materials. This industrial mill is widely used in production lines for powders such as cement, silicates, new building materials, refractory material, fertilizers, ore dressing of non-ferrous metals, glass-ceramics, etc.

At Sinomaly, known for our leading cement production lines, we also offer a wide range of ball mills tailored to meet various industrial needs. Our range of products include mills from 1.5m to 6.7m in diameter, with power capacities reaching up to 10,000 kW. Our dedicated R&D team enhances the design and functionality of these mills, ensuring they meet specific client requirements efficiently. This commitment to innovation and customization underscores our approach to providing industry-aligned solutions, particularly in cement production.

| Size (Φ x L) | RPM (r/min) | Material Feed Size (mm) | Capacity (T/hr) | Ball Load (T) | Motor Power (kW) |

| Φ2.6x10 | 20.8 | ≤25 | 21-24 | 64 | 800 |

| Φ2.6x13 | 20.8 | ≤25 | 28-31 | 81 | 1000 |

| Φ3x9 | 19.13 | ≤25 | 40-45 | 85 | 1000 |

| Φ3x11 | 18.92 | ≤25 | 44-47 | 95 | 1250 |

| Φ3x12 | 18.92 | ≤25 | 48-52 | 103 | 1250 |

| Φ3x13 | 18.92 | ≤25 | 48-52 | 116 | 1400 |

| Φ3.2x11 | 18.3 | ≤25 | 45-48 | 112 | 1400 |

| Φ3.2x13 | 18.7 | ≤25 | 50-55 | 133 | 1600 |

| Φ3.4x11 | 18 | ≤25 | 45-55 | 120 | 1600 |

| Φ3.5x13 | 17 | ≤25 | 60-65 | 156 | 2000 |

| Φ3.8x13 | 17 | ≤25 | 60-70 | 190 | 2500 |

| Φ3.8x13 | 17 | ≤25 | 60-70 | 185 | 2500 |

| Φ4x13 | 16.3 | ≤25 | 70-80 | 191 | 2800 |

| Φ4.2x11 | 15.8 | ≤25 | 100-110 | 190 | 2800 |

| Φ4.2x13 | 15.8 | ≤25 | 120-130 | 240 | 3350 |

| Φ4.2x13 | 15.8 | ≤2 | 180-200 | 240 | 3350 |

| Φ4.8x14 | 15 | ≤25 | 100-115 | 285 | 4200 |

| Parts | Quantity | Weight | Material |

| Rotating cylinder | 1 Set | 219300 kg | 20g-Z25, Medium alloy steel |

| Slide shoe bearing at inlet end (equipped with temperature sensor pt100) | 1 Set | 13700 kg | ZSnSb11Cu6 |

| Slide shoe bearing at outlet end (equipped with temperature sensor pt100) | 1 Set | 13500 kg | ZSnSb11Cu6 |

| Discharge unit (equipped with stand) | 1 Set | 893 kg | Structural parts |

| Discharge outlet cover (equipped with stand) | 1 Set | 14400 kg | Structural parts |

| Slide shoe installation kit | 1 Set | 255 kg | Structural parts |

| Slide shoe lubrication system | 2 Sets | 486 kg | / |

| Gear | 1 Set | 119000 kg | / |

| Total | 9 Sets | 381534 kg | / |

Feeding Device

Materials are sent into the ball grinding mill through the feeding device which has adopted the structure of sloping blinds for a smoother feeding process. The feeding device is equipped with an internal replaceable liner plate, as well as sealing device at the joint connecting with a rotating cylinder to prevent the entry of cold air. Spacers can be put between the air inlet pipe and the stand to adjust the height of the feeding device when necessary.

The Exterior of Feeding Device

The Exterior of Feeding Device The Interior of Feeding Device

The Interior of Feeding Device

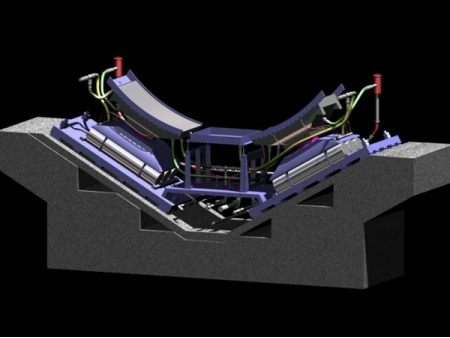

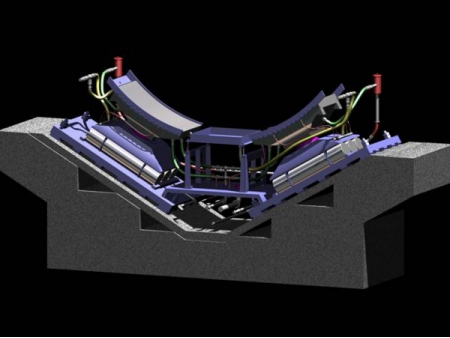

Slide Shoe Bearing

The slide shoe bearing can adjust the position automatically when the ball grinding mill rotates, driving the axial movement of the shoe rotation and the rotating cylinder.

Slide Shoe Bearing Model

Slide Shoe Bearing Model Slide Shoe Bearing Sole Plate Installation Site

Slide Shoe Bearing Sole Plate Installation Site Spherical Seat and Lubrication Circuit of Slide Shoe Bearing

Spherical Seat and Lubrication Circuit of Slide Shoe Bearing

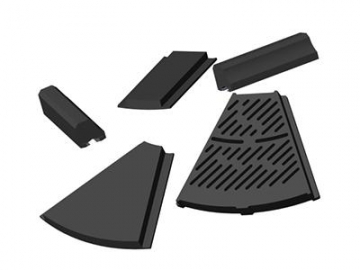

Rotating Cylinder

The rotating cylinder is a key part of the ball grinding mill, which is made up of a hollow shaft, shell, lifter bars, diaphragm, and liner plate. The grate plate is made of wear-resistant cast steel considering that the balls may wear down the inner surface of the cylinder shell. Meanwhile, the grate plate is equipped with a ball return unit to increase the vent area.

Discharge Unit

The air outlet is located at the top of the discharge unit, while the discharge outlet is located at the bottom of the discharge unit. And the discharge unit is equipped with an inspection door for convenient inspection and maintenance.

Gear

This ball grinding mill is equipped with two stage planetary reduction gearboxes which change the fixed axis to a movable axis, thus improving the transmission efficiency to 96% which is 7.3% higher than common ball grinding mills, resulting in outstanding energy efficiency.

- Advantages of this ball grinding mill include: less friction, less energy and more easily activated, because large diameter double row self-aligning roller bearing instead of sliding bearing is used as the main bearing.

- This ball grinding mill can achieve bigger capacity thanks to larger size of feed inlet and discharge outlet.

- There are two kinds of feeder: combination feeder and drum feeder. Both are simple and installed separately.

- This ball grinding mill is suitable for long and stable operation as there is no impact force, thus resulting in high efficiency and less time spent on maintenance.