QC12K(Y) Hydraulic Swing Beam Shear

When designing the QC12K(Y) hydraulic sheet metal shear, we decided to have a back gauge that uses an ABBA ball screw and counting function for cutting is also added in the metal shearing machine.

- 4×2500

- 6×2500

- 10×3200

- 12×2500

-

The metal shear display the position of the back gauge in real time, which is convenient for the operator.

The metal shear's multi-stages programing function allows for automatic operation of the back gauge and continuous positioning, achieving the position of back gauge automatic adjustment with excellent precision.

-

The counting function of cutting can display the shear amount in real time, and when the power turned off, it can record the back gauge's position, program and parameters.

-

The back gauge uses an ABBA ball screw, ensuring the accuracy of the back gauge's position, and makes the machine's processing accuracy higher.

| Type | Max. cutting thickNess | Max. cutting width | Worktable panel thickNess | wallboard thickNess | thickNess of kNife rest upstand | Anti-strength of plate | Stroke times | Throat depth | Blade length | Main motor |

| 4×2500 | 4 | 2500 | 35 | 25 | 35 | 450 | 17 | 130 | 2600 | 5.5kW |

| 4×3200 | 4 | 3200 | 35 | 25 | 35 | 450 | 14 | 130 | 3300 | 5.5kW |

| 4×4000 | 4 | 4000 | 35 | 25 | 35 | 450 | 14 | 130 | 4100 | 5.5kW |

| 4×6000 | 4 | 6000 | 45 | 30 | 45 | 450 | 8 | 130 | 6040 | 7.5kW |

| 6×2500 | 6 | 2500 | 40 | 30 | 40 | 450 | 14 | 130 | 2600 | 7.5kW |

| 6×3200 | 6 | 3200 | 45 | 30 | 40 | 450 | 11 | 130 | 3300 | 7.5kW |

| 6×4000 | 6 | 4000 | 50 | 35 | 50 | 450 | 11 | 130 | 4100 | 7.5kW |

| 6×5000 | 6 | 5000 | 50 | 40 | 50 | 450 | 8 | 130 | 5050 | 11kW |

| 6×6000 | 6 | 6000 | 50 | 40 | 50 | 450 | 8 | 130 | 6040 | 11kW |

| 8×2500 | 8 | 2500 | 45 | 35 | 45 | 450 | 14 | 130 | 2600 | 7.5kW |

| 8×3200 | 8 | 3200 | 50 | 35 | 45 | 450 | 11 | 130 | 3300 | 7.5kW |

| 8×4000 | 8 | 4000 | 50 | 40 | 50 | 450 | 10 | 130 | 4100 | 7.5kW |

| 8×5000 | 8 | 5000 | 50 | 45 | 50 | 450 | 8 | 200 | 5050 | 11kW |

| 8×6000 | 8 | 6000 | 55 | 45 | 50 | 450 | 5 | 130 | 6040 | 11kW |

| 10×3200 | 10 | 3200 | 50 | 45 | 50 | 450 | 10 | 130 | 3300 | 11kW |

| 10×4000 | 10 | 4000 | 50 | 45 | 50 | 450 | 8 | 175 | 4100 | 11kW |

| 12×2500 | 12 | 2500 | 50 | 45 | 50 | 450 | 11 | 175 | 2600 | 18.5kW |

| 12×3200 | 12 | 3200 | 50 | 50 | 50 | 450 | 10 | 175 | 3300 | 18.5kW |

| 12×4000 | 12 | 4000 | 50 | 50 | 50 | 450 | 8 | 175 | 4100 | 18.5kW |

| 12×5000 | 12 | 5000 | 60 | 50 | 60 | 450 | 6 | 200 | 5075 | 22kW |

| 12×6000 | 12 | 6000 | 60 | 50 | 60 | 450 | 6 | 200 | 6040 | 22kW |

| 16×4000 | 16 | 4000 | 60 | 50 | 50 | 450 | 6 | 200 | 4100 | 18.5kW |

| 20×6000 | 20 | 6000 | 80 | 70 | 80 | 450 | 4 | 100 | 6040 | 30kW |

| 25×6000 | 25 | 6000 | 100 | 80 | 100 | 450 | 5 | 200 | 6040 | 45kW |

Ball bed

Ball bed Hold down cylinders

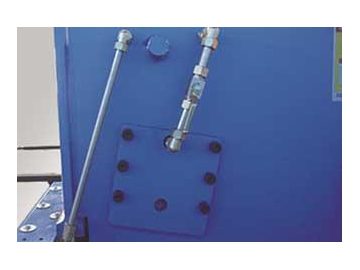

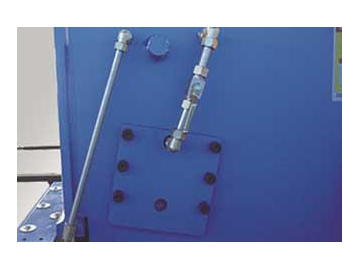

Hold down cylinders Union connector

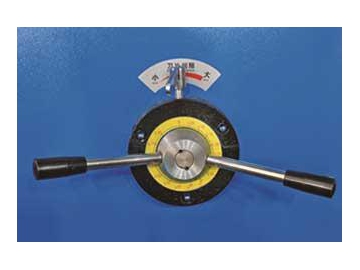

Union connector Blade gap clearance adjust

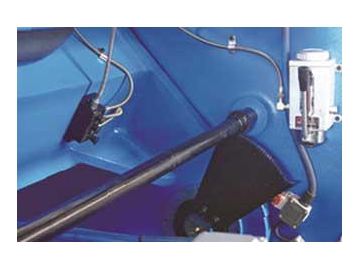

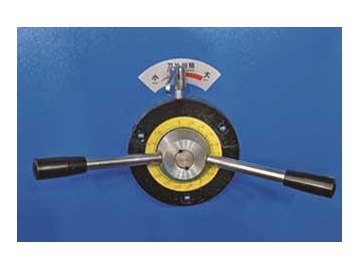

Blade gap clearance adjust Manual refuel device

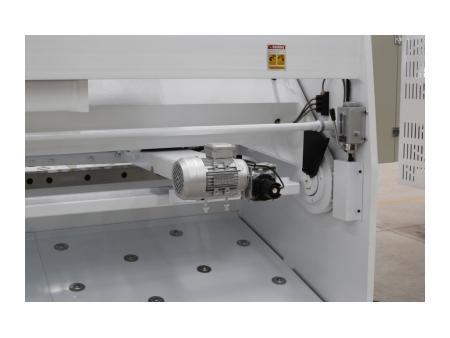

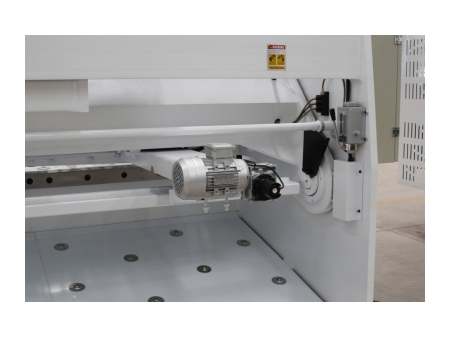

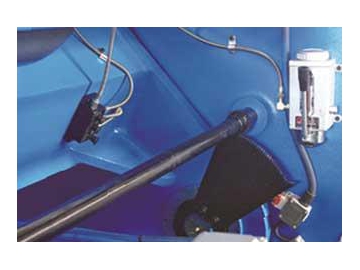

Manual refuel device Back gauge motor

Back gauge motor