Corona Treatment Station

Discharge Station

Corona treatment station, also known as discharge station or discharge treater, is a crucial component of the corona treatment system, commonly used in the corona treatment for materials such as plastic films, metal foils, sheets, and paper. Sanxin offers various types of corona treatment stations for customers to choose from, including double-sided, single-sided, side-open, full-closed, semi-closed, and full-open discharge treaters.

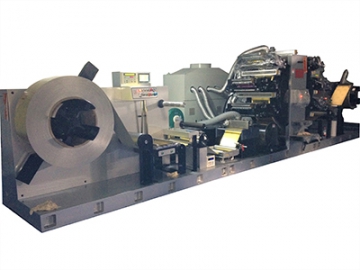

- Power: 40kW

- Processing speed: 250m/min

- Dielectric value (Dyne): >42

Equipped with 4 rollers & 4 electrodes

Matched with W&H film blowing machine for double-side treatment

Siemens PLC control

Corona roller coated with rubber

Corona roller with water cooling system

Aluminum electrodes

Automatic stop for electrode open protection.

- Input Voltage: Three-phase AC 380V, 50Hz

- Output Voltage: Adjustable, up to 15kV

- Electrode: Aluminum, ceramic or segmented

- Power: Adjustable, up to 30kW

- Width: Adjustable

- Speed: Adjustable

- Corona Roller: rubber-coated, rubber-covered or oxidized

- Input Voltage: Three-phase AC 380V, 50Hz

- Output Voltage: Adjustable, up to 15kV

Aluminum electrodes

Available for double-side corona treatment

Corona roller coated with rubber

Corona roller with water cooling system

Corona roller matched with pressure roller to avoid backside corona treatment

Active corona roller matched with production line

Cylinder controlled air compression

Suitable for high-speed production line

- Input Voltage: single-phase 220V, 50Hz

- Output Power: up to 2kW

- Diameter of cable: up to φ15mm

High reliability with IGBT power switching module

Special ceramic electrode for better printing strength of wire and cable

- Input Voltage: Three-phase AC 380V±10%, 50Hz

- Maximum Output Voltage: 15kV

- Maximum Power: 9kW

- Operating Frequency: 18-30kHz

- Operating Temperature: -10℃- 40℃

- Piping Dimensions: Customizable

The discharge treater can make aluminum foil evenly coated with nano-conductive graphite and carbon-coated particles, which collect microcurrents from the active material and thus provide excellent static conductivity. This significantly reduces the contact resistance between the positive/negative electrode materials and the current collector. After corona treatment on the substrate surface, the adhesion between the substrate and the coating is improved, allowing for a reduction in the use of binders and leading to a significant improvement in overall battery performance.

- Input Power: Three-phase 380V ±10%, 50Hz

- Maximum Width for Treatment: 1,500mm

- Maximum Speed for Treatment: 200m/min

1 station can be matched with 2 generators with the power of 8kW/10kW.

More than 12 stations can be equipped for a complete set of corona treater line.

Four sets of single-sided, double channeled ceramic electrodes on each station

Special structural design

Superior processing performance, achieving high Dyne values.

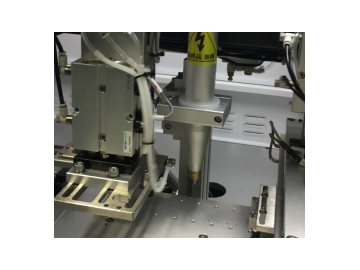

This corona treatment machine is specifically designed for plastic sheets, metal sheets and paper. The treated materials pass through the discharge zone on a conveyor belt, which enhances their adhesive properties. By adjusting the knobs on the control panel, the conveyor belt speed and corona power intensity can be changed to meet different treatment requirements.

- Conveying Belt Speed: 0-20m/min

- Maximum Width for Treatment: 1200mm

- Maximum Corona Power: 8kW

- Minimum Longitudinal Length of Treated Material: 200mm

- Input Voltage: Three-phase 380V, 50Hz

- Output Voltage: Adjustable, up to 15kV

- Operating Frequency: 15-40kHz

- Maximum Width for Treatment: 1,500mm

- Maximum Speed for Treatment: 200m/min

- Total Power: 10kW-20kW

German-imported ceramic electrodes

Ceramic-coated, motor-driven corona roller with water cooling

Siemens PLC controlled

Communication port available

Compatible with ozone treatment machine

- Model: CW3002

- Input Voltage, Frequency: 220V± 10%, 50/60Hz

- Maximum Input Power: 2kVA

- Operating Frequency: 19±1kHz

- Effective Width for Treatment: 300-350mm

- Adjustable Distance between Electrode and Treated Material: 0-6mm

- Effective Front-to-Back Stroke: 400-800mm

- Conveying Mode: ① Moving the electrode ② Moving the worktable

- Electrode Material: Ceramic

Ozone Treatment Device Equipped

The structure of the corona electret discharge station can be customized according to the customer’s production site. The entire equipment is designed to meet the different widths and production line speeds of the filtering materials.

- Input Voltage: 380V, 50Hz

- Input Current: 4A

- Output Voltage: 100kV

- Maximum Width for Treatment: 5,000mm

- Equipped with winding and unwinding system

- Corona treatment allows for better filtration of melt-blown nonwoven fabrics.

- Maximum Input Voltage: AC 220V, 50Hz

- Maximum Input Current: 4A

- The Voltage of Electrode: 10kV

- Output Power: adjustable from 0kW to 1kW

- Maximum speed: 500m/min

- Application: surface treatment of the paper cup, plastic cup and plastic barrel.