Copper Extruder Line

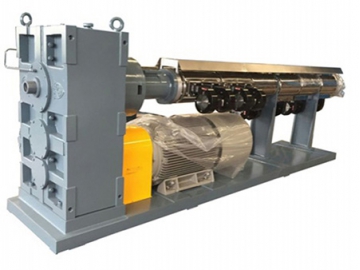

Continuous Extrusion Machine for Copper Busbar

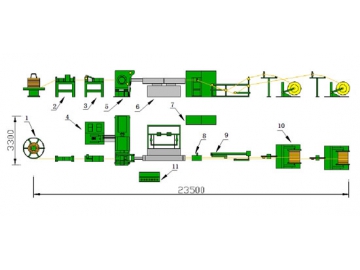

Our range of copper busbar continuous rotary extrusion line is mainly composed of the payoff machine, straightening machine, cutting machine, continuous rotary extrusion machine, cooling machine, take-up machine, and more. The complete layout eliminates users' demand for acquiring different types of auxiliary equipment and also helps save acquisition cost due to our competitive prices.

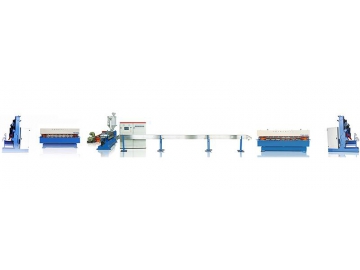

The continuous rotary extrusion line supports producing copper products with a wide range of specifications. In addition to busbar, this production line can also be applied to produce other products such as the copper strip, copper rod, etc., simply by changing the extrusion die.

- Simplified production flow

Unlike press working process during which the friction force is useless, continuous extrusion process can use the friction for feedstock heating. Based on this principle, our copper busbar continuous rotary extrusion equipment can make full use of the friction force to achieve heating and thermal deformation of the feedstock.

Thus, copper busbar and other copper strips can be produced at a stroke through continuous extrusion, without the demand of other machines such as annealing furnace, heating equipment, acid pickling machine, and edge trimming machine. This is why our continuous rotary extrusion line can assist in reducing production and investment costs. - Fine end product quality

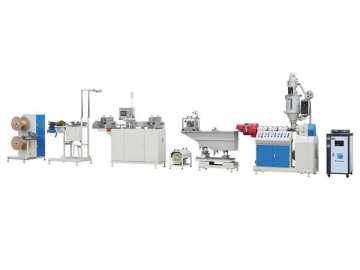

While eliminating surface defects, the hot extrusion process also avoids mechanical damages to material surface. Hence, copper busbars and other types of copper strip produced by continuous extrusion machine have smooth outlines and fine surface quality.

Thermal deformation process eliminates the demand of annealing, which avoids non-uniform quality caused by improper treatment. This makes sure the extruded copper products have consistent quality.

Additionally, the simplified production procedure further improves surface quality by preventing collisions that may otherwise occur from prolonged processing. - Resource saving

Due to reduced production steps, the continuous rotary extrusion line for copper busbars offers reduced energy consumption and low labor force requirement accordingly. Without the demand for end product edge trimming, continuous extrusion machines ensure high utilization rate of materials. - Accurate size

Equipped with high quality extrusion die, the continuous extruding machine makes sure all finished products have precise sizes and exceptional sectional shape.

Copper Wire Manufacturing Equipment, Continuous Extrusion Line, Cable Production Line, Continuous Rotary Extrusion Equipment Manufacturer