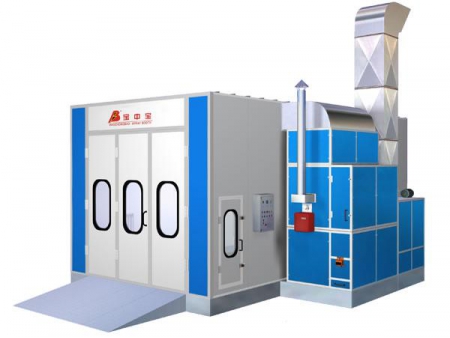

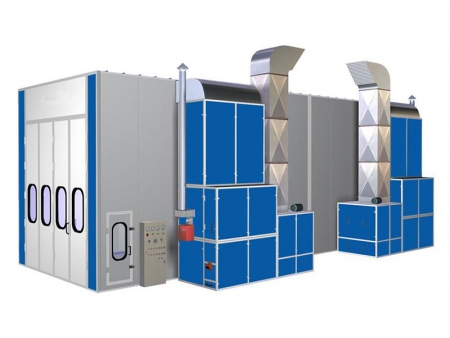

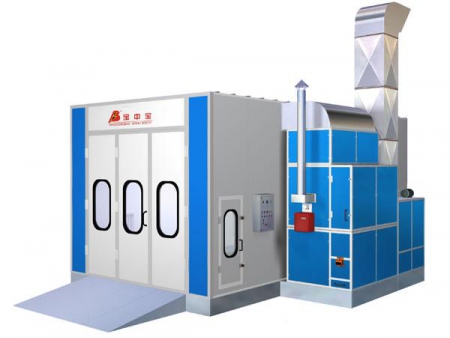

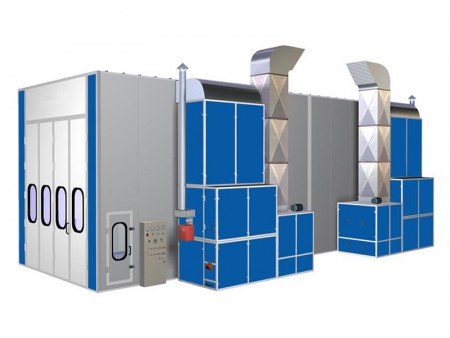

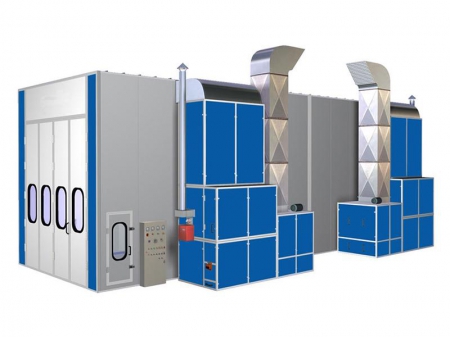

BZB-FB-900 9m Bus Spray Booth

Request a Quote

Superiority

This BZB-FB-9009m bus spray booth can be suited for the sheet metal painting and maintaining of diversified transportation facilities, such as the small-sized vans, and the minibus of 7m long with at most 12 seats, among others.

With solid strength, we can well guarantee the design and manufacturing of this series product. We give a technical design in accordance with the site conditions and environmental requirements for installation. Our 9m bus spray booth is fully guaranteed to be practical, economical, safe, and energy-efficient.

Characteristics

- The basement is 350mm high. It has a load capacity of 3.5 tons. Additionally, it is designed with 4 ramps.

- Our wallboard is composed of the fire-resistant polystyrene insulation board of 50mm thick as well as the colorful steel plate of 0.426mm.

- For supplying air, two 7.5kW centrifugal fans are adopted. For exhausting air, one 11kW large-impeller fan is utilized, which is driven by the belt. In this way, the air change ratio inside the chamber can be guaranteed, and the paint mist can be well discharged.

- Moreover, our 9m bus spray booth puts to use a set of RG5S burner which comes from Italy Riello brand.

- All light tubes are equipped with the renowned-brand electronic ballast. In comparison with the former electronic lamps, they can give more stable performance.

- As an option, this 9m bus spray booth can come without a basement. The return air can be achieved from either two rows of trench or the side.

Configuration List

| External Dimension (mm) | Internal Dimension (mm) | Gate Size (mm) | Total Power (kW) |

| 9106×6356×4450 | 9000×4500×3500 | 3300(width)×3400(height) | 29.5 |

| Basement | 1. The basement is formed of the galvanized steel plate of 350mm high and the anti-corrosive square steel frame. It is configured with two gratings and three checkered plates. 2. The platform gives a load capacity of less than 3.5 tons. Four ramps of 800mm wide are made of anti-skid checkered plates. | ||

| Front Door | 1. This 9m car spray booth is designed with three single doors. 2. The door frame makes use of the aluminum alloy profile by adopting the professional die sinking technology. 3. The framework of the chamber is formed of the galvanized steel plate. | ||

| Service Door | A service door is utilized with the dimension of 700×2000mm (W×H). It is assembled with a pressure lock. | ||

| Chamber | 1. Our 9m bus spray booth takes advantage of the insertion type EPS board. The wallboard is 50mm thick and 1150mm wide. Additionally, the colorful steel plate is used with the thickness of 0.426mm. 2. Premium-quality galvanized steel plates are pieced together to form the roof panel. | ||

| Air Supply System | 1. Two double-inlet centrifugal type supply fans with external rotor are equipped. They possess the model of YDW5.6B, the power of 7.5kW, and the air capacity of 20,000m3/h. 2. The cabinet is formed of the coated profile and the coated steel plate. | ||

| Air Exhaust System | 1. An 11kW centrifugal type exhaust fan with large impeller is used with the model of 4-82. It is driven by a belt, and has an air capacity of 36000m3/h. 2. The cabinet comprises the coated profile and the coated steel plate. 3. The exhaust duct is constructed from the superior-quality galvanized steel plate and the professionally manufactured flange. | ||

| Heating System | 1. This 9m bus spray booth is installed with a Riello-brand RG5S type burner, which gives a maximum heating value of 260,000Kcal/h. 2. The heat exchanger is made from reliable-quality SUS304 stainless steel by adoption of argon arc welding technology. 3. The electric actuator is imported from Switzerland with original packaging. It allows the automatic changeover of spraying and curing to come true. 4. The highest temperature reaches 80 degrees Celsius. | ||

| Purification System | 1. The superior-quality filter screen is used for the primary filtration of intake air. It can take hold of the dust particles with the diameter of over 10μm. 2. The highly efficient filter at the top of our 9m bus spray booth adopts the flame-retardant filter screen made in the Netherlands. It succeeds in seizing the granules with the diameter of over 4μm. 3. The floor filter is made from fiberglass in Italy. A differential pressure gauge is utilized. The TSP value is at most 1.4mg/m3. | ||

| Lighting System | 1.On the side of the ceiling, there are 48 pieces of 18W LED light tubes in 12 groups. Each group holds 4 pieces of light tubes. 2. On the side of the waist stands totally 16 pieces of 18W LED lamps in 8 groups.Each group accommodates 2 piece of lamps. 3. Our 9m bus spray booth is mounted with the ballast which can be connected with two light tubes. 4. The light intensity reaches 800Lux. | ||

| Electric Control System | 1. A face plate with buttons serves to control this system. 2. The main circuit is designed with multiple protective functions. 3. The system takes advantage of the lighting switch, temperature and time settings, room-temperature or constant-temperature spraying, curing switch, emergency stop switch, fault alarm, timer, temperature limiter, and some others. | ||

| Exhaust Gas Treatment | The activated carbon is utilized to filter waste gas. The exhaust emissions reach the GB16297-1996 national standard. (on basis of the integrated emission standard of air pollutants) | ||

We know what you need!

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos