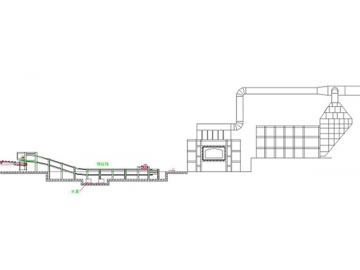

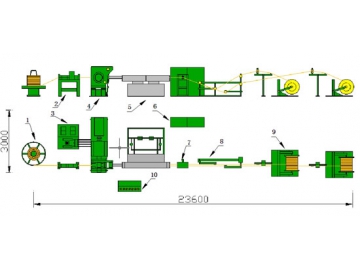

Spray Cooling System (Secondary Cooling) of Continuous Casting System

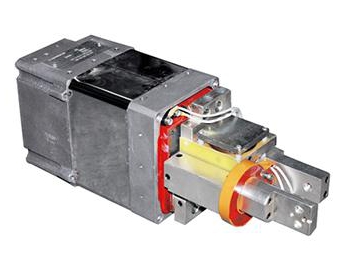

Secondary cooling is carried out after the steel billet is withdrawn from the mold system. It aims for forced and even cooling on the billet surface to solidify the billet in a shorter time. Our spray cooling system adopts electromagnetic flowmeter. The electromagnetic regulating valve and pneumatic valve driven spraying media is water or the mixing of water and air.

Liquid steel is cooled in the mold system and the strand is withdrawn out of the mold system with a shell thickness of only 8-15cm. But the strand center is still high-temperature liquid steel. To quickly solidify and smoothly draw the steel billet, the continuous casting equipment is equipped with secondary cooling and guiding devices. Secondary cooling is controlled by manual. The cooling strength has a great impact on the quality of steel billet. Usually the secondary cooling adopts principles of top-to-bottom and a strong-to-weak cooling strength. Different cooling strengths should be adopted based on the steel grades.