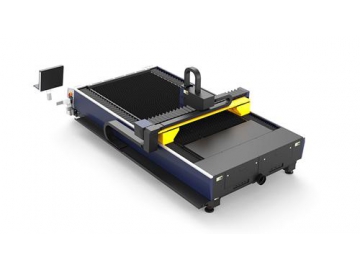

G3015C Fiber Laser Cutting Machine with Gear Rack Dual Drive

Although the power of G3015C fiber laser cutting machine is 1000W, which is slightly lower than the G3015A, the G3015C is popular with small, start up users due to its open structure, easy operation and high cost performance.

Applicable materials: stainless steel and aluminum of 0.5-8mm, carbon steel of 0.5-16mm, brass of 0.5-6mm, copper of 0.5-4mm, galvanized plates, cold-rolled sheets and more.

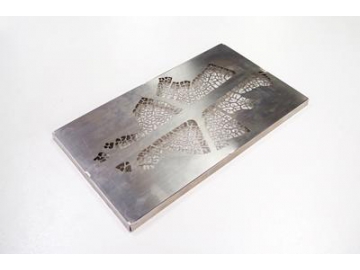

Application industry: The G3015C laser cutter is widely used for external processing of metal sheets, home decorations (window grilles, laser-cut screen door), elevators, aerospace components,instruments and more.

| Processing Area | 3000mm×1500mm |

| Laser Power | 500W-1000W |

| Max. Cutting Speed | 100m/min |

| Max. accelerated | 1.0G |

| X/Y Positioning Accuracy | 0.05mm/m |

| X/Y Repeated Positioning Accuracy | ±0.05mm |

| Power supply | 380V 50Hz |

| Whole machine weight | 3300Kg |

| Machine dimensions | 4600mm×2600mm×1650mm |

* Customizable size: 4m×2m, 6m×2m, 8m×2m.

** We offer lasers in a variety of powers. The material and thickness levels to be cut directly depend on the laser power.

- Stainless steel

- Carbon steel

- Galvanized steel

- Cold rolled steel

- Titanium

- Electrolytic steel

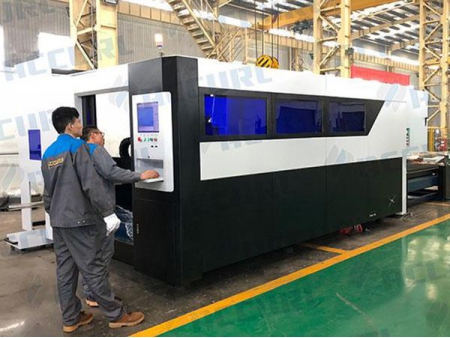

- Laser systemIPG High power fiber laser system features powerful cutting ability.

- Cutting headWe adopt the cutting head produced by ourselves, the core optic of which is from ophir. The optic has high stability.

- High strength machineThe metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life

- Servo motorThe electric and drive systems provided by Japan Panasonic offer customers a faster rotation speed and better stability.

- Rack and gear reducerOur company can customize tungsten steel transmission racks that are more durable, through our strategic partner YYC.