Industrial Cable Manufacturer

Request a Quote

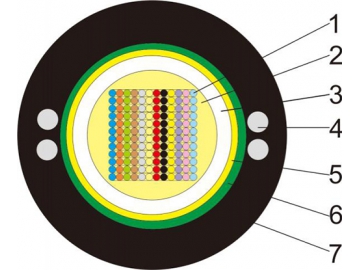

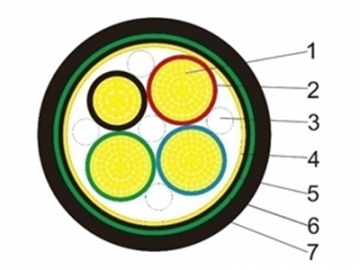

- Optical fiber

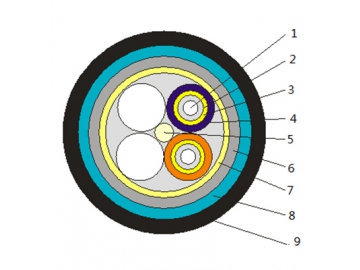

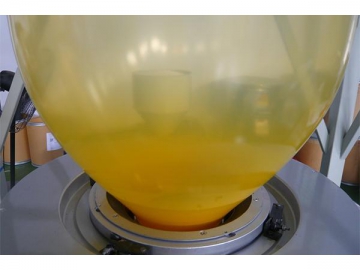

- The optical gel is filled in optical cables before they are completed and sheathed to pass waterproof tests and infiltration tests.

- The buffer tube is a kind of the thermoplastic material and is made of polypropylene can nylon. The buffer tuber can be put in fiber cable loosely and protect optical fiber from interior stress and outer side pressure.

- The strength member: two parallel phosphatized steel wire.

- The water proofing material: filling compound

- Armored layer: steel-plastics tape

- The outer jacket uses black polyethylene and is easy to lay and transport.

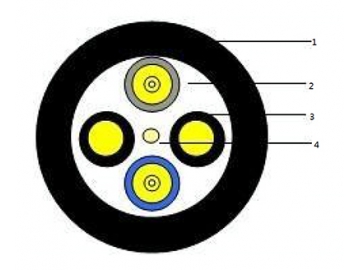

We insert av single-mode or multi-mode into the loose tube made of high modulus polyester material and filled with water proof compounds. The external of loose tube is vertical wrapped double chromium-plated plastic steel tape. Water blocking material is added between the steel belt and loose tube to ensure the compact and vertical water blocking of the cable. Extruded polyethylene sheath into cable with two parallel wires placed on both sides.

Application of Central Tube Ribbon Fiber CableThe central tube ribbon fiber cable is suitable for access to network and interoffice communication (GYDXTW)

Parameter 1. Technical parameter| Item | Content | Value | |||||||

| Number of cable cores | 48 | 72 | 96 | 144 | 192 | 216 | 288 | 576 | |

| Loose tube | Outer diameter | 6.4 | 6.7 | 7.4 | 8.7 | 10.1 | 10.9 | 12.6 | 16.2 |

| Belt and tube structure | 12F*4 | 12F*6 | 12F*8 | 12F*12 | 12F*16 | 12F*18 | 12F*24 | 24F*24 | |

| Reference outer diameter | mm | 12.5 | 13.0 | 13.5 | 15.0 | 16.0 | 17.0 | 18.5 | 22.0 |

| Central strength member | Material | Steel wire | |||||||

| Diameter*amount(mm)* | 1.0*4 | ||||||||

| Material | Water blocking cable gel | ||||||||

| Water blocking material | Material | Corrugated steel belt | |||||||

| Armored layer | Thickness(0.2mm) | 2.3 | |||||||

| Outer sheath | -40- +70 | ||||||||

| Range of operating temperature | Short-term/long-term(N) | 1000/3000 | |||||||

| Pull | 1000/3000 | ||||||||

| *According to customer requirements, the stranded loose tube armored cable can customize other structures or cores. | |||||||||

| G.652.D | G.655 | 50/125m | 62.5/125m | ||

| Attenuation | @850nm | - | - | 3.0dB/km | 3.0dB/km |

| @1300nm | - | - | 1.0dB/km | 1.0dB/km | |

| @1310nm | 0.36dB/km | 0.36dB/km | - | - | |

| @1550nm | 0.22dB/km | 0.23dB/km | - | - | |

| Band width | @850nm | - | - | 500MHzkm | 200MHzkm |

| @1300nm | - | - | 1000MHzkm | 600MHzkm | |

| Fiber cutoff wavelength | 1260nm | 1260nm | - | - | |

| Polarization Mode Dispersion | Single optical fiber | 0.20ps/km | 0.20ps/km | - | - |

| Link value(M=20Q=0.01%) | 0.10ps/km | 0.10ps/km | - | - | |

| Item | Inspection standard | Specified value | Requirements |

| Pull | IEC 60794-1-2-E1 | According to technical parameter | Additional attenuation for short term:0.1dB |

| Flatten | IEC 60794-1-2-E3 | According to technical parameter | Additional attenuation for short term:0.1dB |

| Impact | IEC 60794-1-2-E4 | The height is 1 meter punch hammer 450g at least 50 times1 450g 5 | Residual additional attenuation:0.03dB |

| Backward and forward bending | IEC 60794-1-2-E6 | Loading 150N 30times | Residual additional attenuation:0.03dB |

| Twisting | IEC 60794-1-2-E7 | 1 meters 180 10 | Residual additional attenuation:0.03dB |

| Temperature recycle test | IEC 60794-1-2-F1 | -40 +70 | Change of additional attenuation0.05dB/km |

| * The monitoring of all optical fiber attenuations change is operated in wavelength of 1550nm. | |||

- The cable has characteristics of low attenuation and low dispersion.

- The tube has good flexibility and anti- bending capacity.

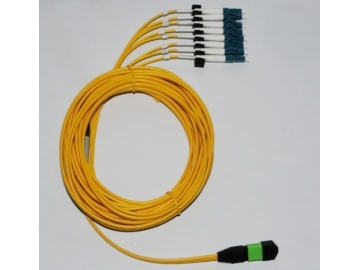

- We use the high quality 12, 24 core belt of the pacific optical cable, so the installation is flexible.

- The unique steady surplus control technology make the cable has the excellent machinery and environment performance.

- The structure of optical fiber belt has high number of core.

- The steel wire armoring has good anti-pressure performance.

Duct, Aerial, Directly burial

Operating StandardsYD/T 981.2-2009 access network fiber ribbon cable Section 2

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos