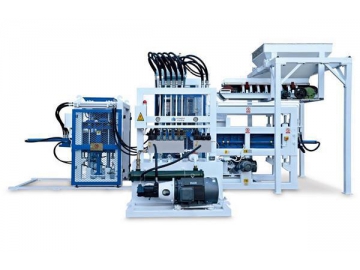

QT6-15 Concrete Block Brick Machine

| Overall dimension(mm) | 4290×1950×2750mm |

| Pallet size(mm) | 880×680×20mm (PVC board) 880×680×10mm (steel sheet) |

| Machine weight(kg) | 10500kg |

| Mode of vibration | Table and mould vibration |

| Frequency of vibration(hz) | 50-70hz |

| Molding cycle(s) | 15s |

| Installed capacity(kw) | 31kw |

1. Vibration System

The QT6-15 concrete block brick machine is equipped with double-shaft synchronous vibration system which can be used to produce different products by adopting different vibration modes.

The vibration system adopts rigid transmission which features no kinetic energy loss. This system can also ensure precise synchronization, lower consumption and better excitation effect. The system has the effect of vertical synchronous vibration, fast molding speed and high products density.

2. Control System

1) The production line uses automated computer control with mechatronics and hydraulics integration all way from automatically mixing materials to stacking finished products.

2) The control system adopts PLC touch screen, man-machine interface which can be remotely controlled. It also has the function of fault self-diagnosing etc.

Economy investment model:

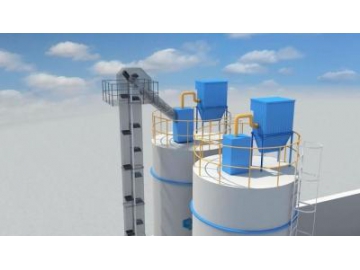

1. The QT6-15 concrete block brick machine and production line is equipped with electronic batching plant which has the following functions: automatic material weighing, automatic cement transportation and measuring, automatic water measuring and adding and automatic material mixing. When the production of block brick is finished, the finished products can be transported by forklift which can realize stereoscopic stacking for natural curing.

2. This production line can be quickly put into production, covering a small area. It just requires simple basic facilities. There only needs 7-15 workdays from normal installation to putting into production, so that this machine is quite suitable for individual investors and beginners of running a factory.

3. The production line can be composed by several QT6-15 concrete block brick machines. It can be put into production after being equipped with automatic electronic dosing and material loading machine.

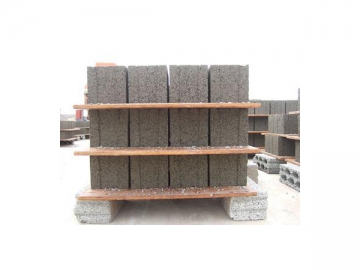

4. This concrete block brick machine can be used to produce various hollow brick and paving bricks etc. This machine needs few operators which means that it only needs 3-4 personnel directly engaged in production. So this production line features low investment cost.

| Specification of products (mm) | Number of blocks per pallet | Pieces/1 hour | Pieces/8hours | Pieces/300 day(two shifts) | ||

| Block |  | 390×190×190 | 6 | 1,400 | 11,520 | 6,912,000 |

| Hollow Brick |  | 240×115×90 | 15 | 3,600 | 28,800 | 17,280,000 |

| Paving Brick |  | 225×112.5×60 | 15 | 3,600 | 28,800 | 17,280,000 |

| Standard Brick |  | 240×115×53 | 30 | 7,200 | 57,600 | 34,560,000 |

| Theoretical yield: it will change with different raw materials and intensity requirements. | ||||||

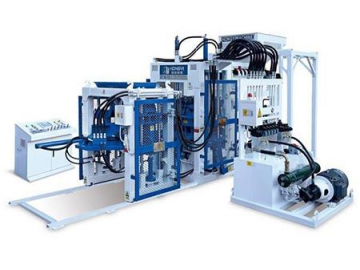

QT6-15 concrete block brick machine, QT10-15 concrete block brick machine, S shaped block brick machine.

QT6-15 concrete block brick machine, colorful block brick machine.