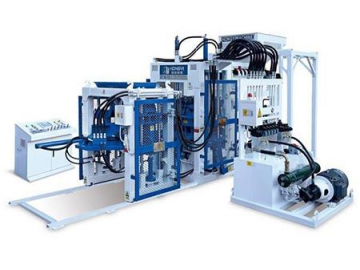

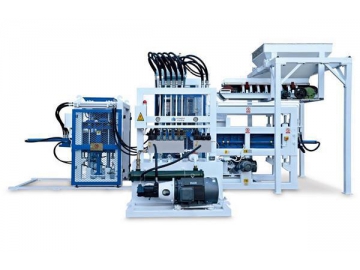

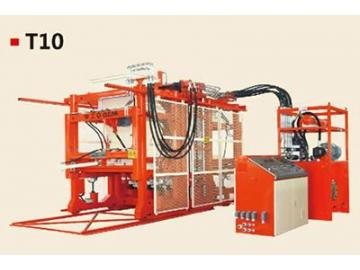

QT8-15 Concrete Block Brick Machine

| Overall dimension(mm) | 4290×2150×2750mm |

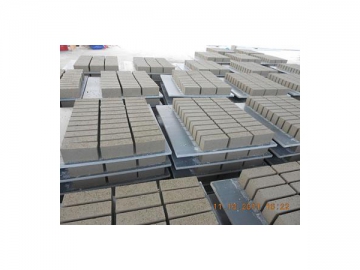

| Pallet size(mm) | 880×880×20mm (PVC board) 880×880×10mm (steel sheet) |

| Machine weight(kg) | 11500kg |

| Mode of vibration | Table and mould vibration |

| Frequency of vibration(hz) | 50-70hz |

| Molding cycle(s) | 15s |

| Installed capacity(kw) | 32.5kw |

The QT8-15 concrete block brick machine consists of the following systems:

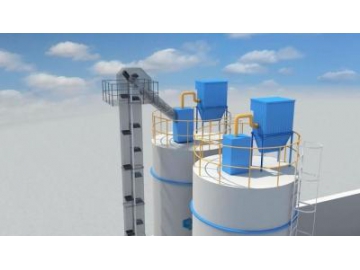

1. Material storage and distribution system: it is uniquely designed to guarantee the accuracy of material supply and distribution, reduce the uneven density caused by self pressure and external factor, thus producing high density products.

2. Vibration system: 1) It adopts variable frequency synchronous vibration of which the frequency can be adjusted according to different production process. It can realize charging at low frequency, while shaping at high frequency. The changes of the amplitude and frequency during the process of frequency adjustment can help to produce solid and dense block bricks.

2) This vibration system is suitable for large-scale block brick machine which is controlled remotely by computer.

3. Control system: Hongyi has collected many production parameters and integrated them into the control system of the machine by many years of practical experiences. So it is more convenient to adjust the operation of the machine according to the raw material and wanted products during the production.

4. Automated self-diagnosis: 1) The computer fault automatic self-diagnosing system is attached to the machine to serve an alarm reporting function and thus facilitate the elimination of any faults.

2) This system can be connected with the remote control system through wired Ethernet or wireless connection to realize remote monitoring, control and diagnosis.

Investment mode:

The production process of the QT8-15 concrete block brick machine consists of material loading carried out by loading machine, mixing and transportation to the block brick machine, automatic finished product stacking and finished product transportation carried out by forklift to the natural curing chamber.

The simplified investment mode of this machine is the same as that of the QT6-15 concrete block brick machine. But compared with QT6-15, the production value of this machine can be increased by 20% by just increasing 15% equipment investment. It just need 3-4 production operators as well. So the production efficiency is remarkably improved.

| Specification of products (mm) | Number of blocks per pallet | Pieces/1 hour | Pieces/8hours | Pieces/300 day(two shifts) | ||

| Block |  | 390×190×190 400×200×200 | 8 | 1,920 | 15,360 | 9,216,000 |

| Hollow Brick |  | 240×115×90 | 18 | 4,320 | 34,560 | 20,736,000 |

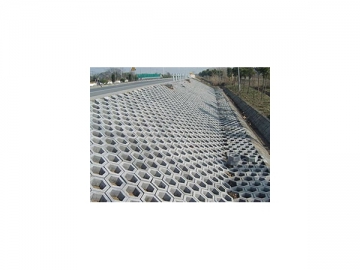

| Paving Brick |  | 225×112.5×60 | 18 | 4,320 | 34,560 | 20,736,000 |