Industrial Cable Manufacturer

Request a Quote

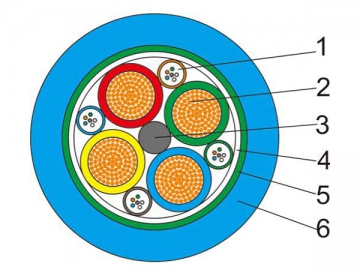

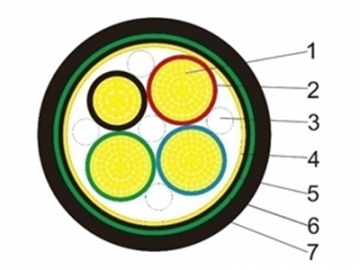

- Optical unit

- Feeder line

- Central strength member

- Water-blocking material

- Armored layer: composite steel-plastic tape

- Outer sheath: blue polyvinyl chloride

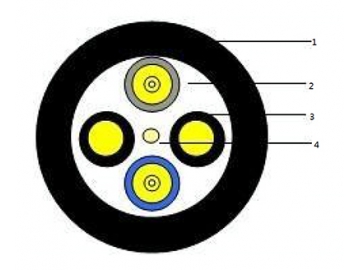

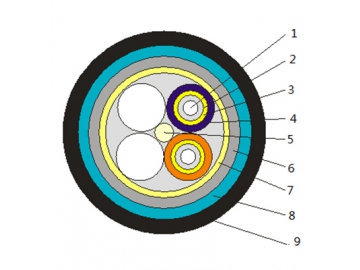

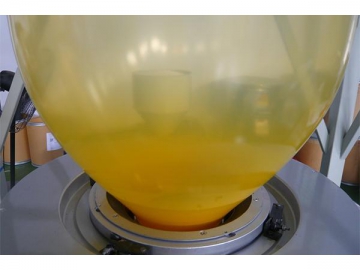

The mining photoelectric fiber composite cable uses 250μm optical fiber in the loose tube of high modulus material and fill waterproof compound into the loose tube.

We use a metal strength member (with a layer of PE) as the cable core.

The loose tubes (with filler strip) and wire are stranded around the strength member into a compact and tight cable core which is filled with the filling compound to protect it from water ingress.

Polyethylene layer should be extruded out of the metal strength member to form the loose tube.

Parameter Technical parameter| Specification | Reference outer diameter (mm) | Tensile Strength (Long term/N short term/N) | Flattening force Long term/short term (N/100mm) |

| GDTS 2-24B1.3+2*1.5mm² | 11.5 | 600/1500 | 300/1000 |

| GDTS 2-24B1.3+2*2.5mm² | 12.5 | ||

| GDTS 2-24B1.3+2*4.0mm² | 13.5 | ||

| GDTS 2-96B1.3+2*6.0mm² | 17.5 | ||

| GDTS 2-96B1.3+2*10.0mm² | 19.0 | ||

| GDTS 2-24B1.3+4*1.5mm² | 11.5 | ||

| GDTS 2-24B1.3+4*2.5mm² | 12.5 | ||

| GDTS 2-24B1.3+4*4.0mm² | 13.5 | ||

| GDTS 2-96B1.3+4*6.0mm² | 17.5 | ||

| GDTS 2-96B1.3+4*10.0mm² | 19.0 | ||

| * 2*1.5 shows the quantity and specification of conductor; 2-24B1.3 identifies the quantity of cable core and specification od optical fiber; * We can design the sectional area and quantity of core according to customer's requirement. * The sheath is made of blue flame retardant PVC. | |||

| G.652.D | G.655 | 50/125μm | 62.5/125μm | ||

| Attenuation | @850nm | - | - | ≤3.0dB/km | ≤3.0dB/km |

| @1300nm | - | - | ≤1.0dB/km | ≤1.0dB/km | |

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | - | - | |

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | - | - | |

| Bandwidth | @850nm | - | - | ≥500MHz·km | ≥200MHz·km |

| @1300nm | - | - | ≥1000MHz·km | ≥600MHz·km | |

| Fiber cutoff wavelength | ≤1260nm | ≤1260nm | - | - | |

| Polarization mode dispersion | Single optical fiber | ≤0.20ps/√km | ≤0.20ps/√km | - | - |

| Link value (M=20, Q=0.01%) | ≤0.10ps/√km | - | - | ||

| Item | Inspection standard | Procedure of inspection | Requirements |

| Pull | IEC 60794-1-2-E1 | According to technical parameter | Additional attenuation for short term≤0.1dB |

| Flatten | IEC 60794-1-2-E3 | According to technical parameter | Additional attenuation for short term≤0.1dB |

| Impact | IEC 60794-1-2-E4 | Area of punch hammer: 12.5mm², height:1m, 5 times | Residual additional attenuation≤0.03dB |

| Backward and forward bending | IEC 60794-1-2-E6 | Load: 150N, 30 times | Residual additional attenuation≤0.03dB |

| Twisting | IEC 60794-1-2-E7 | 1m , ±180°, 10 times | Residual additional attenuation≤0.03dB |

| Temperature recycle test | IEC 60794-1-2-F1 | -40℃ ~+70℃ | Additional attenuation ≤0.05dB |

| Combustion performance | IEC 60332-1-2 | Fire resistance | The optical fiber will maintain its attenuation uniformity. |

| Flame retardant: every single wire can be burnt vertically. | The distance between lower edge of upper fixture and burnt point:>50mm | ||

| Flame retardant: combustion for bunched cable | Height of carbonized part<2.5m | ||

| Density of the smoke | Light transmittance ≥50% | ||

| * The monitoring of all optical fiber attenuation's change is operated in wavelength of 1550nm. | |||

- This optical cable has great toughness and mechanical properties.

- This product is photoelectric integrated and will sufficiently save pipeline resources.

- This optical cable is suitable for pipeline and aerial usage.

- The tight buffered optical fiber has an excellent flame retardant performance.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos