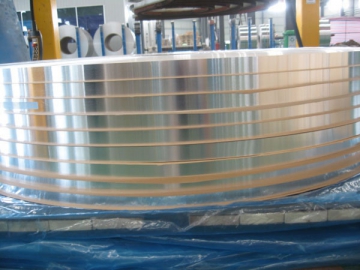

Aluminum Brazing Sheet

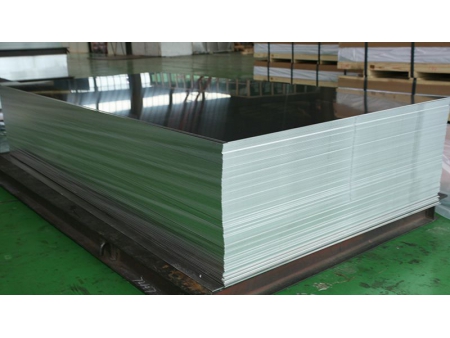

AluminumSheet

_

Our company is committed todeveloping aluminum brazing sheets andexploring solutions which can increase the values of customers’ products.

Application

1. Our range of aluminum brazing sheet is adapted for different kindsof brazing processes, such as Nocolokbrazing and vacuum brazing. Available in bothaluminum sheets and aluminium coils, they can be widely used in theparts of automobile engine and air conditioning system, such asradiator, condenser, evaporator, charge air cooler, oil cooler and fan heater.

2. The brazingmaterial is also suitable formicro-channel heat exchanger, water heater and PTC heating unit of homeappliances.

3. In industrial field, our aluminum brazing sheet can be applied to thecooling system of thermal power station, engineering machinery and gasseparation equipment.

Due to its stable clad ratio, reliable mechanical property and excellentcorrosion resistance, our aluminumclad material has a good reputation among customers.

Our company has specially designed many new aluminumbrazing sheets for heat exchangers to meet the technical requirements ofdifferent customers. According to different application demands, we havedeveloped the aluminum alloy sheet material for radiator, sagging resistance brazing aluminum alloy for finand high-strength ageing-strength brazing aluminum alloy for main plate.

Standard CoreAlloy & Brazing Alloy

| Core Alloy | Brazing Technique | Application | Property |

| AA3003 | CAB,VB | Plate | Average strength |

| YB304 | CAB | Fin | High strength |

| YB307 | CAB | Plate | High strength |

| YB308 | CAB | Plate | High strength, long lifespan alloy |

| YB309 | CAB | Plate | High strength, long lifespan alloy |

| YB311 | CAB | Radiator tube | High strength, long lifespan alloy |

| YB508 | CAB | Radiator tube | High strength, long lifespan alloy |

| AA6951 | VB | Oil cooler plate | High strength |

| AA6060 | VB | Oil cooler plate | High strength |

| AA6063 | VB | Oil cooler plate | High strength |

| (1) CAB brazing alloy: AA4343, AA4045, AA4343 1%Zn, AA4045 1%Zn. (2) VB brazing alloy: AA4004, AA4104. | |||

Remark: CAB refersbrazing process of controlled atmosphere which using

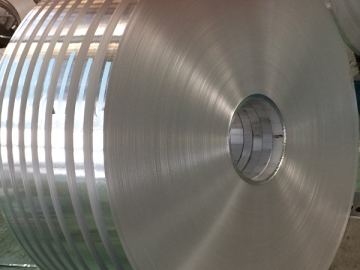

Specification

|

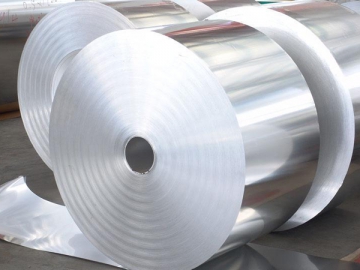

| Aluminum Brazing Sheet in Coils | Aluminum Brazing Sheets |

| Thickness | 0.06 up to | 0.4 up to |

| Width | 12 up to | 450 up to |

| Length |

| Max. |

| Tolerance standard | Conforming to DIN, EN, ASME standards | |

| Inner diameter | 100, 200, 250, 300, 400, |

|

| Outer diameter | |

|

| Surface | Mill finish | |

| Cladding | one-side; double-side; multi-layer cladding | |

| Cladding thickness | 4℅ - 30℅ | |

| Cladding thickness tolerance | Cladding thickness of 4℅ -6℅ : /-1.5℅ | |

| Cladding thickness of 6℅ -12℅ : /-2℅ | ||

| Cladding thickness of 12℅ -16℅ : /-2.5℅ | ||

| Cladding thickness of 16℅ -20℅ : /-3℅ | ||

| Cladding thickness of 20℅ -30℅ : /-4℅ | ||

| Marking | Ink marking | |

In order to facilitate your purchasing, we prepare you some forms showing theinformation of aluminum brazing sheetssuitable for different applications. You can download the forms by yourself orcontact our salesmen to learn about the detailed information.

: Materialsfor radiator _Materials forRadiator1.pdf

:

(PFC):

:Materialsfor Charge Air Cooler _Materials for CAC1.pdf

:

:Materialsfor air cooler of power station _Materialsfor Air Cooler of the Power Station1.pdf