CNC Hydraulic Plate Bending Machine, 4 Roll

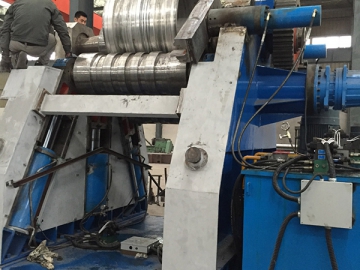

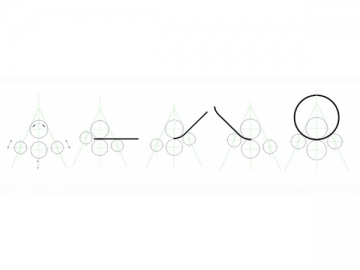

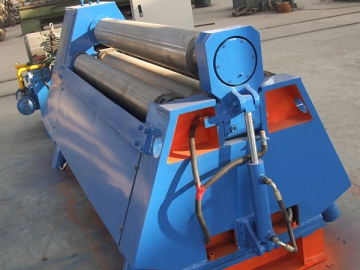

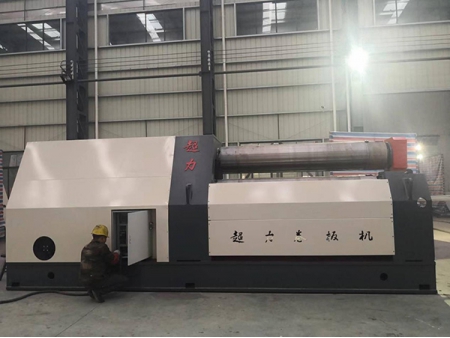

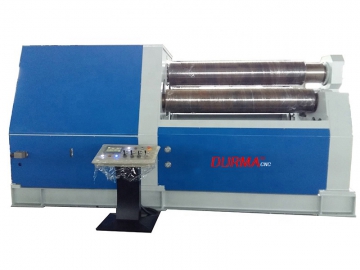

Our W12NC series CNC hydraulic plate bending machine is a now state of the art 4 roll plate roll in the world, combined with the extreme versatility, proven reliability, and performance. It can pre-bend the end of plate in both sides without having to turn it the other way around. For fabricators, welding shops, maintenance shops and production applications in oil, chemical, boiler, shipbuilding hydro power, metal structure and machine manufacturing industries, this 4 roll plate bender is preferred choice for rolling cylindrical, arc and conical workpieces.

Model Selection

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-6×1500 | 1500 | 6 | 5 | 5.5 | 160 | 245 | 145 | 190 | 140 | 11 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-12×2500 | 2500 | 12 | 8 | 5 | 400 | 245 | 240 | 260 | 200 | 15 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-20×2200 | 2200 | 20 | 12 | 4.5 | 600 | 245 | 350 | 320 | 240 | 15 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-25×2500 | 2500 | 25 | 20 | 4.5 | 800 | 245 | 430 | 380 | 320 | 30 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-40×1500 | 1500 | 40 | 30 | 4.5 | 1200 | 245 | 350/640 | 340/620 | 280/520 | 22 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-40×2500 | 2500 | 40 | 32 | 4.5 | 1200 | 245 | 550 | 530 | 380 | 37 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-40×3000 | 3000 | 40 | 32 | 4 | 1600 | 245 | 580 | 520 | 400 | 45 |

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| W12NC-50×2500 | 2500 | 50 | 42 | 4.5 | 1600 | 245 | 580 | 520 | 400 | 45 |

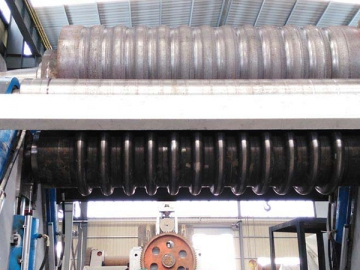

For Corrugated Sheets

W12NC-10×220 is not only a common 4-roll plate bending machine, but it is also able to roll corrugated steel cylinders with an addition of special tooling on the top and lower working rolls. It can complete pre-bending and rolling at a stroke without having to turn the material the other way around. This bending roll is an ideal choice for making corrugated tanks in boiler and heat exchanger industries.

Features

1. The top and lower pinch rolls of the 4-roll plate rolling machine share the same diameter, making it sure that bending dies on them are interchangeable, thus reducing cost.

2. The high strength corrugated dies are specially designed, suitable for rolling cylinders in different width and corrugations.

3. Hydraulic drop end and balancing device at the end of top roll ensure easy and stable unloading of finished workpiece.

| Max. rolling thickness | 25mm /10mm corrugated sheet |

| Pre-rolling thickness | 20mm /10mm corrugated sheet |

| Rolling width | 2200mm |

| Yield limit of plate | 245MPa |

| Min. rolling diameter | Φ600mm |

| Top roll diameter | Ф360mm(not including mold)/ Ф496(including mold) |

| Lower roll diameter | Ф360mm(not including mold)/Ф496(including mold) |

| Side roll diameter | Ф270mm |

| Rolling speed | ~4m/min |

| Lower roll lifting speed | ~130 |

| Side roll lifting speed | ~310 |

| Hydraulic system pressure | ~18MPa |

| Motor power | Y200L-4-B35 30KW 1470rpm |

| Dimensions (mm) | 3630*2060*2030 |

| Machine weight | ~20800Kg |

Features

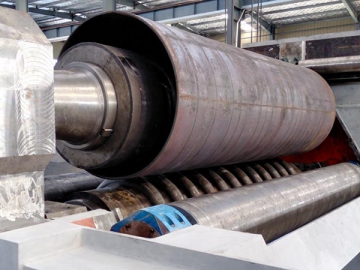

1. The hydraulic plate bending machine comes with four rolls. Top roll is driven by gear reducer or hydraulic motor to offer torque for bending. Pinch roll is driven by hydraulic cylinder to move vertically. Two side rolls driven by hydraulic cylinders move up and down slantwise.

2. Four rolls are all made of 42CrMo steel. Forging and surface hardening processes provide the HB250~280 surface hardness, excellent wear resistance and long lifespan.

3. Bearings at two ends of the working roll are self-aligning roller bearings, ensuring small friction coefficient, reducing power consumption and saving energy.

4. The CNC plate roll is designed with a high precision displacement sensor for monitoring the positions of pinch roll and side rolls.

5. An encoder is mounted on the top roll to clearly pinpoint the rotation position of the roll and thereby to easily find the seam of cylinder.

6. Mobile CNC control panel is provided for easy operation. Through the touch screen on the panel, operator can clearly see the positions of three working rolls.

7. The control system with OMRON intelligent PLC controller boasts strong resistance to interference, high longevity, remarkable running stability and other notable advantages.

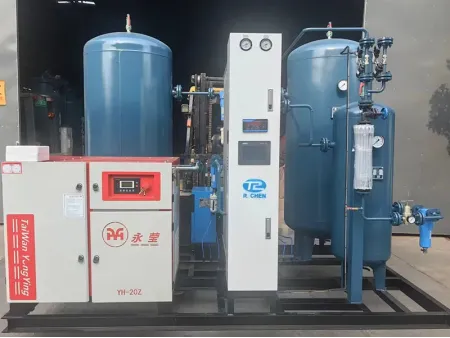

8. Main hydraulic manifolds are from Taiwan NORTHMAN, which come with large flow, tiny resistance, low pressure loss and low heat.

9. Hydraulic driven drop end delivers high reliability and convenience for finished components unloading.

10. The 4 roll plate bending machine is fitted with a balancing device at the end of top roll to balance the top roll when the drop end turns over.

11. The hydraulic system comes with oil filter for system cleaning as well as air filter for normal air in and out of oil tank and water evaporation. It is equipped with a double-way safety protection device to maximize safety in use.

12. Hydraulic drop end of the 4 roll plate bending machine, namely unloading device is driven by a hydraulic cylinder to realize automatic drop and erection, thus ensuring ease of workpiece unloading. Due to an interlocking device, other actions of the machine will stand by when the hydraulic drop end turns over, and only after the drop end erects can the machine runs again. This ensures high safety.

Applicable Industries

The sheet metal bending machine is excellent for use in tank truck, chimney, chemical, hydro power, thermal power, shipbuilding, aviation, pressure vessel, pipe, tunnel, bridge, metal structure and machine manufacturing industries.

Juli's Service Assurance

1.Professional after-sales team, on-site installation and commissioning, free operator training;

2. One-year warranty, free maintenance during warranty period, abundant inventory of quick wear parts.

| Model | Max. rolling width (mm) | Max. rolling thickness (mm) | Pre-rolling thickness (mm) | Rolling speed (m/min) | Min. rolling diameter of full loading (mm) | Yield limit of plate (MPa) | Top roll diameter (mm) | Lower roll diameter (mm) | Side roll diameter (mm) | Main electric motor (kw) |

| 2000 | 12 | 8 | 4.5 | 600 | 245 | 240 | 220 | 180 | 22 | |

| 4000 | 12 | 8 | 4.5 | 800 | 245 | 380 | 340 | 280 | 30 | |

| 2500 | 20 | 16 | 4.5 | 800 | 245 | 380 | 340 | 280 | 30 | |

| 2500 | 25 | 20 | 4.5 | 800 | 245 | 430 | 380 | 320 | 30 | |

| 2500 | 40 | 32 | 4.5 | 1200 | 245 | 550 | 530 | 380 | 37 | |

| 3200 | 40 | 32 | 4.5 | 1300 | 245 | 650 | 580 | 480 | 45 | |

| 2500 | 50 | 42 | 4.5 | 1600 | 245 | 580 | 520 | 400 | 45 | |

| 3200 | 50 | 42 | 4 | 1800 | 245 | 680 | 650 | 520 | 45 | |

| 2500 | 60 | 50 | 4 | 1800 | 245 | 640 | 600 | 480 | 75 | |

| 3200 | 60 | 50 | 3.5 | 2000 | 245 | 700 | 680 | 550 | 75 | |

| 3000 | 70 | 60 | 3.5 | 2000 | 245 | 750 | 720 | 600 | 125 | |

| 3200 | 80 | 70 | 3 | 2200 | 245 | 800 | 780 | 620 | 132 | |

| 4000 | 90 | 80 | 3 | 3500 | 245 | 900 | 880 | 700 | 180 | |

| Due to continuous product improvement, actual data might vary slightly. If that happens, please follow the technical parameters of mutual agreement. Juli reserves the right to revise design, construction and specifications without prior notice. | ||||||||||

Related Names

Rolling Cylindrical | Arc and Conical Workpieces Machine