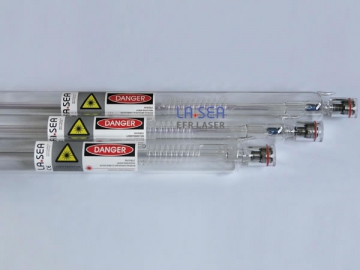

ZX Series CO2 Laser Tube

Country of Origin: China

Product Standard: Q/EFR/J 1.1-2012

Certifications: CE certificate, Chinese technical letters patent

Overview

We use unique technology in glass to metal sealing, and US II-VI branded optics and core technology from radar technology to ensure the ZX series CO2 laser tube is leak proof, solving the problem of a changed output mode due to a deformed optical cavity.

EFR has spent 3 years developing this laser accessory for laser equipment and formally put it into production in May of 2011. This CO2 laser tube features a stable property and a maximum power up to 180W. When compared to ordinary laser tubes, it is more compact in size, has a better beam mode, a smaller light spot and a faster cutting speed.

Parameters

| Model | Length (mm) | Outer Diameter (mm) | Output Power (W) | Maximum Power (W) | Operating Current (mA) | Catalyst |

| 1,250 ±2 | Ø80 ±2 | 80 | 95 | 28 | Yes | |

| 1,450 ±2 | Ø80 ±2 | 100 | 120 | 30 | Yes | |

| 1,650 ±2 | Ø80 ±2 | 130 | 150 | 30 | Yes | |

| 1,850 ±2 | Ø80 ±2 | 150 | 180 | 30 | Yes |

Product Showcase

Characteristics

Excellent Leak Proof Performance: Due to the unique technology of glass to metal sealing and a core technology based on radar technology, the CO2 laser tube is guaranteed to have a leak proof performance.

High Power: Equipped with a fully reflecting mirror, and a window originally made by the US II-VI brand, the CO2 laser tube has 40% more power than other laser tubes of the same length, and the maximum power is 180W.

Long Service Life: The discharge tube is galvanized with a catalyst, and has electrodes that are specially treated, giving the sealed laser tube a longer service life of up to 10,000 hours, and maintaining a stable operation for a long period of time.

Great Beam Mode: The cost-effective CO2 laser tube can be used in industrial applications due to its optical cavity, high quality laser beam, and stable laser power. Its beam mode can achieve TEM00.

Precision Spare Parts: Processed using machine tools imported from Japan, all spare parts and accessories have a high precision and excellent stability.

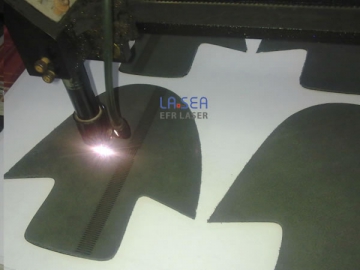

Performance and Application: EFR's high power, durable and stable CO2 laser tubes have a small light spot and can be used as laser cutting machine accessories, laser engraving machine accessories, and laser marking machine accessories. As they play an important part in cutting, engraving and marking of leather products, car seats, clothes, paper, and other products in the advertising, packaging, craft processing, decorative construction material industries, our laser consumables are widely recognized and popular among numerous manufacturers of laser machines.

Cutting: ZX-1650 and ZX-1850 CO2 laser tubes meet different processing requirements in the advertising, exhibition, decoration, clothing, and leather products industries.

Engraving: ZX-1650 and ZX-1850 CO2 laser tubes can achieve a high frequency pulse engraving under preionization conditions.

Operating Condition

Water cooling:

Cooling liquid: clean water

Flow rate: 3-5L/min. (ZX-1250 CO2 laser tube has the flow rate of 2-5L/min.) Standard water temperature: 10℃-40℃

Ambient: temperature: 2℃ -40℃; humidity: 10-60%

Operating Current

| Model | Input Current | Max. Operating Current | Max. Current in long-term operation | Service Life | Matched EFR Power Supply | Starting Voltage |

| ZX-1250 | 28mA | 29mA and below | 27mA and below | 8,000 hours (operating current ≤ 25mA) | PS-N80 | 19 KV |

| ZX-1450 | 30mA | 28mA and below | 28mA and below | 10,000 hours (operating current ≤ 26mA) | PS-N100 | 24 KV |

| ZX-1650 | 30mA | 28mA and below | 28mA and below | 10,000 hours (operating current ≤ 28mA) | PS-N130 | 28KV |

| ZX-1850 | 30mA | 28mA and below | 28mA and below | 10,000 hours (operating current ≤ 28mA) | PS-N130 | 28KV |

**Note: The ZX-1650 CO2 laser tube allows the input current to be 30mA and the maximum operating current to be 28mA. With the operating current no higher than 28mA, the laser tube for medical and industrial use maintains long-term operation, and a service life up to 10,000 hours.

The above currents are based on actual currents displayed on the ammeter, which is in a series connection with the cathode.

If the glass laser tube is incorrectly used under long-term, over-current conditions, the color of the negative electrode will change and the service life will be significantly reduced.

In order to prevent dust from disturbing the interior electrodes, please use plastic wrap to cover the high pressure protective housing.

Cleaning Tips: When cleaning the window of the CO2 laser tube, avoid using cotton swabs or other wipes to scrub the lens, as doing so significantly impacts the output power.

Please clean the window according to the following specified methods:

1. Switch off the laser tube if the lens becomes stained.

2. Blow away dirt on the lens using an air dust blower.

3. Spray ethanol on the lens using a syringe.

4. Allow the ethanol to evaporate, before turning the laser tube back on.

5. If the lens is still not clean, as a professional to use a cotton swab dipped in ethanol to clean the lens in a rotating method outward from the center.

Special Notice

1. Acetone can't be used to clean the lens.

2. Keep the two fastening screws fixed at both ends of the laser tube to prevent it from performing with a decreased power output or being scratched.

3. Please keep organic glass at least 300mm away from the window when testing the light spot.

Safety: When working, please wear eye protection to protect your eyes from invisible light generated by this laser equipment spare part. Please be aware of the high voltage mark on the positive pole.

Storage and Transportation Requirements: The cooling liquid inside the tube should be drained, and the tube ends covered n dustproof plastic bags, Store the laser tube in an ambient temperature ranging from 2 to 40℃, and a humidity ranging from 10-60%.

When transporting the CO2 laser tube, use adhesive tape and sponges to fix the tubes in place in order to prevent sliding. In addition, a 70mm sponge should be used on the end of the window and a 50mm sponge on the end of the fully reflecting mirror.

Package Size

| Model of Laser Tube | ZX-1250 | ZX-1450 | ZX-1650 | ZX-1850 | ZX-2050 |

| Quantity of Laser Tube | 1 | 1 | 1 | 1 | 1 |

| Product Net Weight (Kg) | 2.66kg | 3.1kg | 3.6kg | 3.95kg | 4.4kg |

| Carton Capacity | 1 laser tube (large carton for air transport) | ||||

| Carton Dimension (L×W×H) | 141×32×32 | 161×32×32 | 179×32×32 | 199×32×32 | 219×32×32 |

| Carton Dimension (with Sponge) (L×W×H) | 141×40×40 | 161×40×40 | 179×40×40 | 199×40×40 | 220×40×40 |

| Product Rough Weight (Kg) | 6.2kg | 6.8kg | 7.5kg | 8.1kg | 8.9kg |

| Wooden Box Dimension | 156×46×51 | 176×46×51 | 194×46×51 | 214×46×51 | 234×46×51 |

| Package Rough Weight (Kg) | 26kg | 29kg | 34kg | 42kg | 46kg |

| Dimensional Weight [(L×W×H)/5,000] | 73.2 | 82.58 | 91.03 | 100.41 | 109.79 |

| Dimensional Weight [(L×W×H)/6,000] | 60.99 | 68.82 | 75.85 | 83.67 | 91.49 |

Quality Guarantee

Service life: 10,000 hours

Warranty: 300 days

1. Within the 300 day warranty period, under operation standards specified in the instruction book, if the CO2 laser tube has an output power of less than 80% of the rated power, we will freely replace and repair the laser tube. The newly replaced laser tube is provided under our quality guarantee.

2. Any problems that arise due to improper use are not covered under the warranty.