Vertical EPS Light Wall Panel Production Line

Introduction:

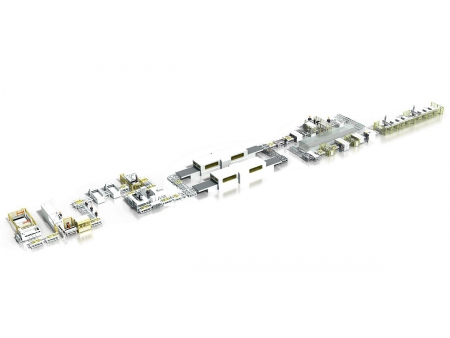

The vertical insulated concrete wall panel production line is an enclosed production line adopting automatic batching system, continuous mixing technology, automatic mould vehicle movement, mould tumbler and automatic mould stripping, digital management system and some other technologies to produce products with complete appearance and high precision.

Features:

The vertical insulated concrete wall panel production line has the following features:

1. This production line needs smaller floor area than other lines during production.

2. The injection process can rapidly fill the die cavity with material. Then the material can be easily tamped without hollowing, thus realizing high productivity.

3. The yield can be increased just by adding the number of mould.

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 75 series | 75 | 2240/2440 | 610 | 50±5 | 2 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 90 series | 90 | 2240/2440 | 610 | 55±5 | 4 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 120 series | 120 | 2240/2440 | 610 | 67±5 | 5 |

| Specification | Thickness(mm) | Length(mm) | Width(mm) | Approx. weight(kg/m2) | Duration of fire resistance(h) |

| 150 series | 150 | 2240/2440 | 610 | 90±5 | 5 |

| Finished wall panel dimension | 3000/2440×610×75/90/100/120/150/180mm | |

| Wall panel yield of different thickness | 75mm | 46 pieces |

| 90mm | 40 pieces | |

| 100mm | 36 pieces | |

| 120mm | 32 pieces | |

| 150mm | 26 pieces | |

| Dimension | 3560×1560×2865mm | |

| Weight | 3.1T | |

| Item | National standard | Detected index | ||||

| 60mm | 90mm | 120mm | 60mm | 90mm | 120mm | |

| Impact resistance/times | ≥5 | ≥5 | ≥5 | ≥8 | ≥10 | ≥15 |

| Bending breaking load/dead weight multiples | ≥1.5 | ≥1.5 | ≥1.5 | ≥3 | ≥4 | ≥5 |

| Compressive strength | ≥3.5 | ≥3.5 | ≥3.5 | ≥5 | ≥5 | ≥5 |

| Softening coefficient | ≥0.80 | ≥0.80 | ≥0.80 | ≥1 | ≥1 | ≥1 |

| Areal densitykg/m2 | ≤70 | ≤90 | ≤110 | ≤55 | ≤70 | ≤85 |

| Moisture contenta/% | ≤12/10/8 | ≤10/9/7 | ||||

| Drying shrinkage/mm/m | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.45 | ≤0.5 | ≤0.5 |

| Lifting capability/N | ≥1000 | ≥1000 | ≥1000 | ≥1200 | ≥1300 | ≥1300 |

| Noise insulation volume/dB | ≥30 | ≥35 | ≥40 | ≥35 | ≥40 | ≥45 |

| Duration of fire resistance/h | ≥1 | ≥1 | ≥1 | ≥1.5 | ≥3 | ≥4 |

| Heat transfer coefficientb/w/m.k | ≤2 | ≤1.5 | ||||

| Specific radioactivity limitation (solid panel) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Ira internal exposure index/Iraexternal exposure index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

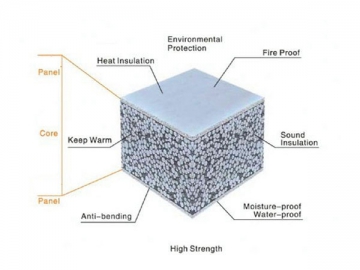

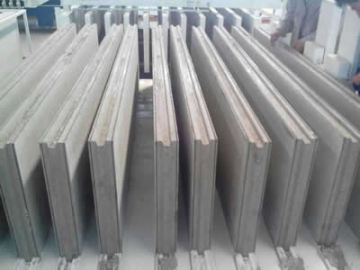

Introduction of composite insulated lightweight wall panel:

The composite insulated lightweight wall panel adopts fiber reinforced calcium silicate board and cement calcium silicate board as the surface panels. The middle is filled with lightweight aggregate such as expanded perlite, ceramsite, shale, EPS particles, cinerite etc.; cementing material such as cement, gypsum, magnesite cement etc.; stuffing such as coal ash, slag, plant fiber, tailings, construction waste etc.; reinforcing material such as fiberglass, steel wire, plastic steel etc. This wall panel is produced by metering and mixing of the said materials. The production adopts mold and cavity.

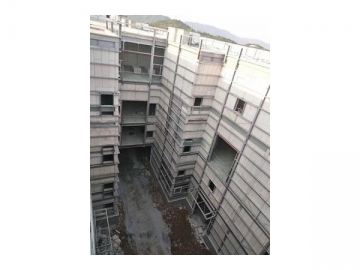

This wall panel is a replacement construction material for red brick, clay brick, hollow brick, block brick, color steel sandwich panel, gypsum block, perlite board with wire gauze, perlite perforated plate etc.

The panel is extensively used for the high and low buildings like the bank, office building, hospital, school, hotel, shopping mall, entertainment place, portable dwellings, reconstructed house, residential building, workshop, etc.

Features of composite insulated lightweight wall panel:

1. Eco-friendly: The vertical insulated concrete wall panel production line produces the A grade panel from eco-friendly composite materials which are free of harmful contents and radioactive substances, meeting the National G/T 169-2005 Standards.

2. Fireproof: At 1000ºC, the panel is tested to keep fire resistance over 4 hours without generating toxic gas.

3. Good integrity and seismic performance: The wall adopts integrative structure of which the panels are connected by tenon, so that the impact resistance is 1.5 times that of the normal masonry wall. It also adopts steel structure for anchoring, thus the wall has high intensity. It can be used as the partition wall with large span of multilayer buildings. Its integral seismic performance is 10 times higher than the ordinary masonry wall. This kind of wall features compact structure, good integrity, no deformation and looseness and good seismic performance.

4. Moisture and water proof: The panel made by our vertical insulated concrete wall panel production line is extremely waterproof and moisture resistant. Therefore, this panel has outstanding adaptability to the places with high humidity, such as kitchen, washroom, basement, etc.

5. Effective sound insulation: Both the calcium silicate board (or cement fiber board) on the surface of the wall panel and the internal filling materials have good sound insulation and absorbing effect. For example, the 90mm thick panel is able to absorb the sound about 43dB, which is higher than other concrete walls do. The sound insolation effect meets the Chinese standard of residence.

6. Capable for nailing and mounting: In the construction, the composite wall panel can be nailed and mounted with expanded bolt for hanging objects such as air-conditioner. The bearable weight of single point exceeds 45kg. As there is no dust on the surface of the panel because the panel surface is smooth and flat, some materials can be adhered to the panel directly, such as tile, wall paint, etc.

7. Light and economical: The 75mm wall panel weighs 1/7 of the 120mm masonry wall, so that the cost of the wall structure is reduced. While the valid space is increased. The construction can be simple and convenient, saving the project cost.

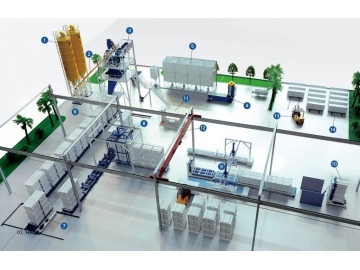

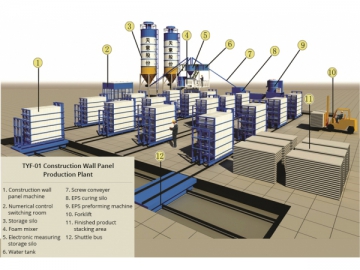

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

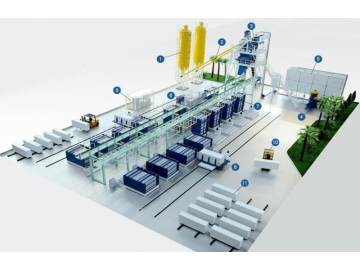

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com

TYF-16A Construction Wall Panel Production Plant (Mobile Type, Calcium Silicate Board Compound Wall, GRC Glass Reinforced Concrete Panel)

wallpanellines.com