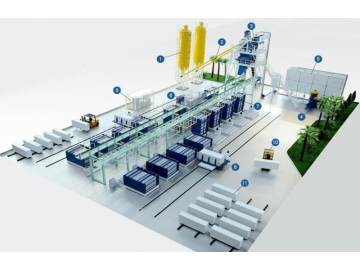

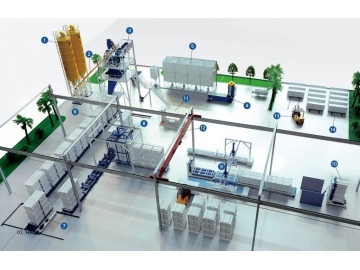

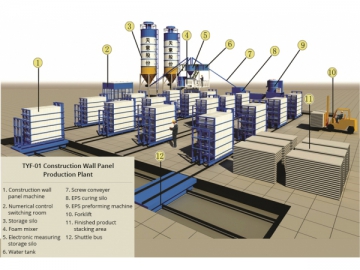

Split Type Vertical EPS Light Weight Wall Panel Production Line

Introduction:

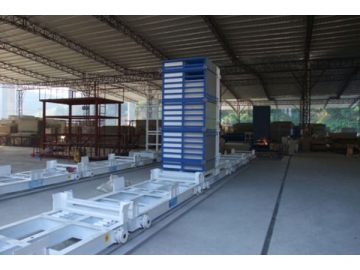

The compound insulated concrete wall panel production line adopts sub and mother mould for automatic molding, curing and circulating production. It can produce composite lightweight insulated wall panel from EPS particles, XPS particles, ceramsite, modified perlite and some other light materials.

This production line consists of automatic batching plant, material metering and transporting equipment, continuous mixing station and material feeding system, sub and mother mould cart, ferry trolley, tumbler, mould stripping machine etc.

Features:

Because of the separated sub mould and mother mould design and the mother mould is on the production line, when the sub mould is gathered in the curing chamber, the mother mould can continuously flow along the line, carrying the other sub mould. So, the production site and scale will not be limited because of on line curing. Thus it can provide larger productivity with limited production site.

| Finished wall panel dimension | 3000 / 2440 × 610 × 75/90/100/120/150 / 180mm | |

| Wall panel yield of different thickness | 75mm | 40 pieces |

| 90mm | 36 pieces | |

| 100mm | 32 pieces | |

| 120mm | 28 pieces | |

| 150mm | 24 pieces | |

| Dimension | 3350 × 1640 × 2920mm | |

| Weight | 4.2T | |

Configuration:

This compound insulated concrete wall panel production line is equipped with the following devices:

1. Vertical mould (vertical split casting);

2. Sub and mother mould which is also called sub and mother mould cart. It consists of vehicle and die set;

3. One sub and mother mould vehicle consists of 2 sub and mother mould and vehicle;

4. Automatic mould tumbler;

5. Specific mould stripping machine.

Introduction of composite insulated lightweight wall panel:

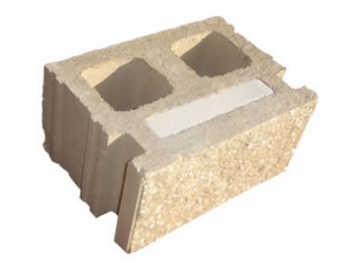

The composite insulated lightweight wall panel adopts fiber reinforced calcium silicate board and cement calcium silicate board as the surface panels. The middle is filled with lightweight aggregate such as expanded perlite, ceramsite, shale, EPS particles, cinerite etc.; cementing material such as cement, gypsum, magnesite cement etc.; stuffing such as coal ash, slag, plant fiber, tailings, construction waste etc.; reinforcing material such as fiberglass, steel wire, plastic steel etc. This wall panel is produced by metering and mixing of the said materials. The production adopts mold and cavity.

This wall panel is a replacement construction material for red brick, clay brick, hollow brick, block brick, color steel sandwich panel, gypsum block, perlite board with wire gauze, perlite perforated plate etc.

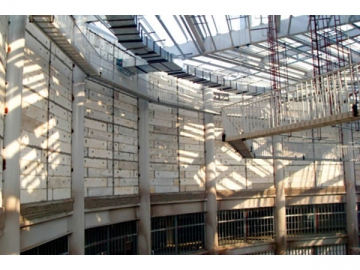

The panel is extensively used for the high and low buildings like the bank, office building, hospital, school, hotel, shopping mall, entertainment place, portable dwellings, reconstructed house, residential building, workshop, etc.

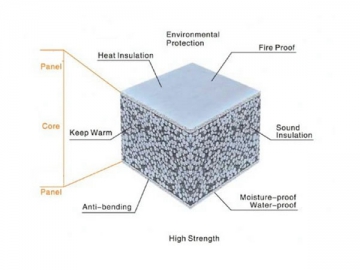

Features of composite insulated lightweight wall panel:

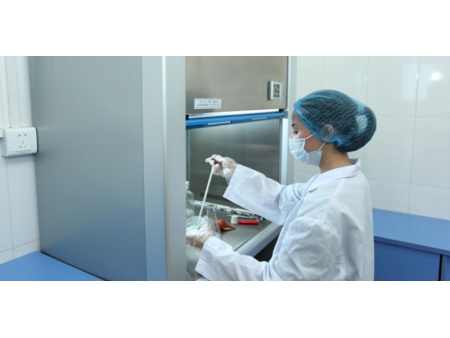

1. Eco-friendly: The compound insulated concrete wall panel production line produces the A grade panel from eco-friendly composite materials which are free of harmful contents and radioactive substances, meeting the National G/T 169-2005 Standards.

2. Fireproof: At 1000ºC, the panel is tested to keep fire resistance over 4 hours without generating toxic gas. The non-combustible performance complies with the A grade national standard.

3. Increasing valid space: The 75mm lightweight composite wall is 85mm less than the 160mm normal internal parting wall and plastering thickness. Which means every additional 11.8m lightweight wall can save 1m in space.

4. Capable for nailing and mounting: In the construction, the composite wall panel can be nailed and mounted with expanded bolt for hanging objects such as air-conditioner. The bearable weight of single point exceeds 45kg. As there is no dust on the surface of the panel because the panel surface is smooth and flat, some materials can be adhered to the panel directly, such as tile, wall paint, etc.

5. Light and economical: The 75mm wall panel weighs 1/7 of the 120mm masonry wall, so that the cost of the wall structure is reduced. While the valid space is increased. The construction can be simple and convenient, saving the project cost.

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com

TYFZ16 Construction Wall Panel Production Plant (Vertical Rotating Type, Lightweight Compound Wall Panel)

wallpanellines.com