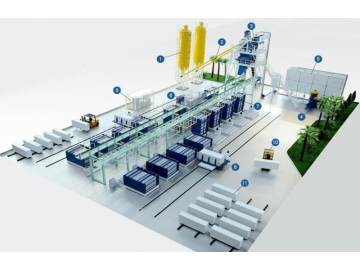

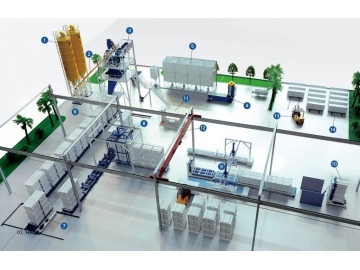

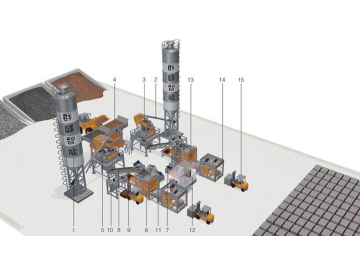

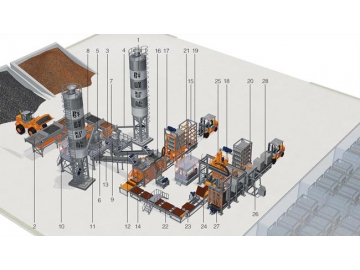

Insulated Foam Concrete Block Production Line

Introduction:

The insulated foam concrete block production line consists of mixing system, batching system, foaming machine, conveyor, transporting equipment, molding equipment, transfer device, curing system, cutting machine, stacking machine, packaging machine etc.

This production line can be used for producing various insulated wall blocks, insulated wall panel, insulated lightweight panel etc. of different specifications.

Introduction of foam concrete block:

The foam concrete block is a kind of material which has large amounts of tiny, enclosed and evenly distributed pores, so this block features lightweight, high intensity, thermal insulation, fire proof, sound insulation and shock absorption etc.

It adopts incombustible material. The fireproof performance can reach A1 grade, so it is a new thermal insulating material which is strongly advocated by the nation. Compared with the foamed plastic, this foam concrete block has good compressive strength, low heat conductivity coefficient, firm adhesion to the building, uniform expansion factor and long service life.

This foam concrete block is suitable for high-rise building wall, surrounding enclosures, thermal insulating floor, sound insulation and shock absorption etc.