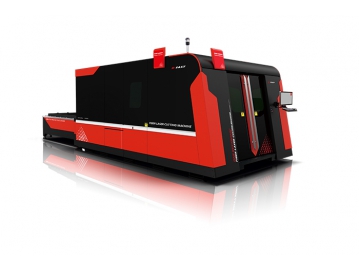

Sheet and Tube Fiber Laser Cutter FCCD

FCCD plate and tube integrated fiber laser cutting machine is a multi-functional equipment. It can not only cut metal sheet, but also cut metal pipes, including square pipe, round pipe, rectangular pipe and all kinds of special-shaped pipes. By combining sheet cutting and pipe cutting functions, the laser cutting machine can significantly save equipment costs and space.

In fact, all fiber laser sheet metal cutting machine of any structure or power can be optionally equipped with pipe cutting system. Therefore, we are able to provide all types of plate and tube integrated laser cutting machines of 1000w-2000w to meet customers' extensive demand for metal cutting.

- Electric power

- Automotive manufacturing

- Electrical equipment

- Commercial kitchen equipment and appliances

- Advertising signs

- Automotive sheet metal production

- Heavy equipment precision parts

- Metal fabrication

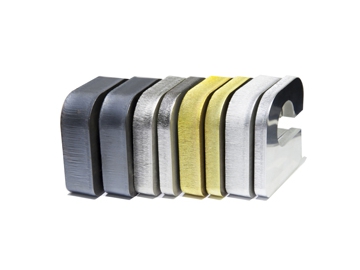

- Stainless steel

- Mild steel

- Galvanized steel

- Electrolytic plate

- Brass plate

- Aluminum plate

- Manganese steel

- Various alloy plate

- Rare metal plate

- 6mm aluminum plate

- 25mm aluminum plate

- 18mm carbon steel plate

- 25mm carbon steel plate

- 21mm brass plate

- 25mm brass plate

Note: if you need to cut metal pipes, choose the pipe cutting function. This feature is optional on all our laser cutter models.

| Power | 1000W | 1500W | 2000W | |

| Maximum power consumption | 13kW | 15kW | 18kW | |

| Cutting table | 1500×3000mm²,1500×4000mm² | |||

| Structure | Single shuttle table open structure/open structure with interchangeable table/fully enclosed structure (optional) | |||

| Floor area (take 1500*3000mm cutting table as an example) | Generally 4700×5000mm²,which can also be customized | |||

| Demand for electricity | 380V,50Hz/60Hz,60A | |||

| Repeated positioning accuracy | ±0.02mm | |||

| Cutting speed | depends on the type and thickness of the material | |||

| Materials | 1000W | 1500W | 2000W |

| Stainless steel | 6mm | 8mm | 10mm |

| Carbon steel | 12mm | 16mm | 16mm |

| Brass | 4mm | 5mm | 8mm |

| Galvanized sheet | 3mm | 3mm | 4mm |

| Aluminum | 4mm | 6mm | 8mm |

- Fiber laser source

Fiber laser is the primary part and the core "power source" of the fiber laser cutting machine. The IPG brand is the world's largest fiber lasers manufacturer, which not only provides the laser electro-optical conversion efficiency of up to 30%, but also provides the semiconductor pump source with a long service life of up to 100,000 hours. So it is truly "maintenance-free".

According to the different requirements of cutting power, we will equip the suitable fiber laser for the plate and tube integrated laser cutting machine.

1000W fiber laser

1000W fiber laser  4000W fiber laser

4000W fiber laser  12000W fiber laser

12000W fiber laser

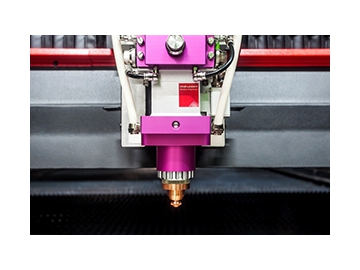

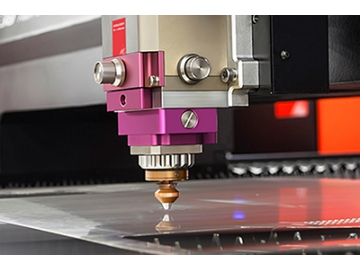

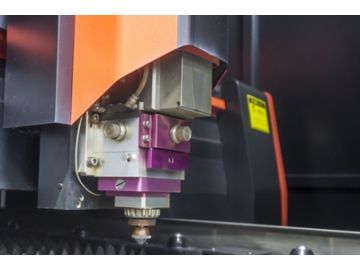

- Laser cutting head

The cutting head is a laser output device, which is composed of a nozzle, a focusing lens and a focusing tracking system. It travels flexibly according to the programmed cutting path to complete the cutting of complex workpiece.

We will provide suitable laser cutting head according to customer's requirement for material type and thickness. For example, for thicker metal plate cutting, not only high power support is required, but also the optical lens structure with longer focal length inside the laser head is used to ensure that the laser beam with high enough energy can be provided. For thinner metal plate cutting, the laser head with a short focal lens is enough.

What's more, all laser heads have auto-focusing function, which means that there is no need to change the focus lens when cutting metal plates of different thickness.

1000W fiber laser

1000W fiber laser  3000W fiber laser

3000W fiber laser  8000W fiber laser

8000W fiber laser

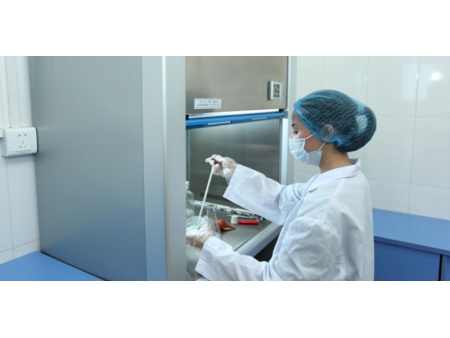

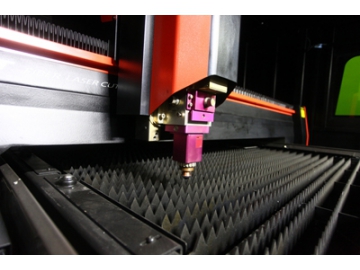

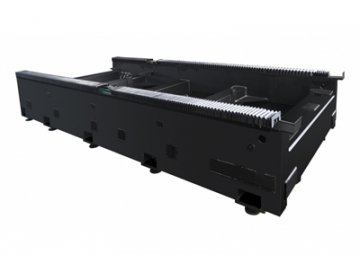

- Machine structure

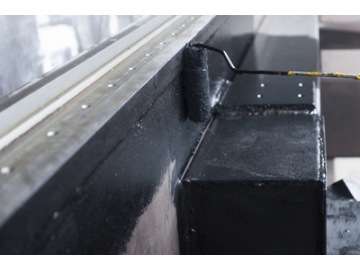

If the precision of the worktable is very high, the precision of cutting will be increased accordingly. Therefore, the precision of the worktable is also a very important factor to ensure fiber laser cutting quality. After high temperature tempering on metal plate, the stress of welding and machining is reduced, and the machining error caused by the vibration of the structure can be reduced.

At the same time, the surface coating is completed by hand brushing. The hand-brush coating can make the service life of machine body extend 20 years at least.

High rigidity machine tool

High rigidity machine tool  The coating is being brushed

The coating is being brushed

- Touch screen

Combined with the technology of Swiss Bystronic and our strong optical development capabilities, we developed and designed an intelligent touch screen control system so that the operation interface is more simple, convenient, and flexible.

- Side-hanging plate and tube integrated cutting machine

With a side-hanging pipe-cutting table, the machine can realize pipe cutting of up to 3 meters. The pipe cutting table is attached to the place where the machine structure is connected with the cross beam, and there is no other support in the middle, which can rotate the pipe unilaterally with the cutting action. - Floor-standing plate and tube integrated cutting machine

With a floor-standing pipe cutting table, the machine can realize pipe cutting of up to 6 meters. Compared with the side-hanging cutting table, the middle part of the cutting table is provided with automatic support, and an additional guide rail and a driving motor are installed. The guide rail can realize automatic feeding and the driving motor can realize completely synchronous rotation with cutting action. Centering clamping can be done manually or automatically.