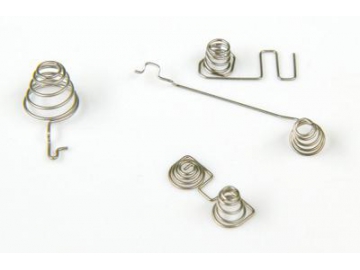

Springs for Coke Oven

Springs of Juneng are manufactured basing on clients' drawings, samples, dimensions, and other detailed requirements. As a large-scale coke oven equipment manufacturer, Juneng provides coke oven springs for over 1000 clients, more than 100 of which cooperate with Juneng for 7.63m, 6.25m, 6.0m, and 5.5m springs, and over 40 of which order coke oven bars and other accessories from us. Juneng is known as reliable quality, reasonable price, good reputation, and considerate service. All of these have won Juneng large popularity among clients.

Technical Parameters| Material | we order steels according to clients' requirements |

| Wire diameter | 0.2mm-100mm |

| Customization | springs are customized basing on clients' drawings, sample, and dimension |

| Surface treatment | painting, coating ,galvanizing, flanging, or others upon customers' request |

| Models | Komatsu, Hitachi, Cater, Kato, Kobelco, Simitomo, Hyundai, etc. |

| Color | as customers' needs |

| Packaging | wooden boxes |

Customizing

1. After receiving clients' drawings, samples or spring dimensions, we will discuss with clients to determine some details, and then the production will start. Technical advisory service is offered for free.

2. Product report and testing result will be sent to customers together with the springs.

Why Choose Us

1. We offer custom springs exactly according to clients' requirements

2. Juneng provides you comprehensive and considerate

3. DN high-speed quenching oil developed by Nanjing University of Aeronautics and Astronautics is used as the quenching medium. It has greatly reduced the deformation and cracking during quenching, as well as improved the hardness of springs.

4. With 3 large CNC salt bath tempering furnace, the internal stress of the springs is eliminated uniformly

5. 6 sets of end grinding machines and M4013 double-end grinding machine are adopted to prevent the overheating phenomenon occurred during grinding

6. Sand blasting is finished by a large suspended rotary shot blasting machine, ensuring a large surface hardness and long service life.

7. We use an advanced CJW-6000 magnetic particle flaw detection machine to check the internal flaws of the heat treated springs,