Custom Filtration

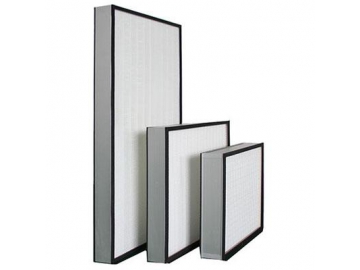

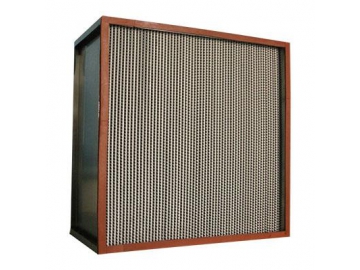

Youjie has been specializing in the production of air filters for more than a decade, our products include a wide variety of high efficiency air filters, air filter replacements, FFUs, high-efficiency air vent filters and other specialized air purification equipment for dust-free workshops. These products can be used in a broad scope of applications demanding high air cleanliness, such as manufacturing plants for optoelectronic products, food, pharmaceutical products, surface treatment plants, soldering plants, and residential fields.

Our factory covers an area of 3,100 m2 and can independently complete all aspects of design, production, processing, testing, etc. In addition to manufacturing common specifications of purification products, we can also deliver OEM and ODM processing according to samples or drawings given to us by customers. Our monthly production can reach up to 10,000 sets.

In terms of industrial filters, customers can provide us with specific requirements such as efficiency, resistance, and installation dimensions under the rated ventilation. Our R&D team will then provide optional solutions accordingly. For the design of filtration products used in pharmaceuticals, hospitals, optics and electronics industries, we will assemble a special team to take full charge of the project.

The assets and materials department is responsible for compiling and releasing purchase orders based on the raw material demand plans or the purchase requirements of materials. Purchase orders are classified and archived monthly.

For suppliers, the assets and materials department will conduct assessment and evaluation management of supply performance and then establish qualified supplier files. The quality department is responsible for formulating raw material inspection standards and conduct inspection and testing accordingly as well as marking and recording. Therefore, all our raw materials sources are traceable and quality is strictly controlled.

Our company maintains a close cooperative relationship with 3M and HV so we can choose materials according to the requirements of customers.

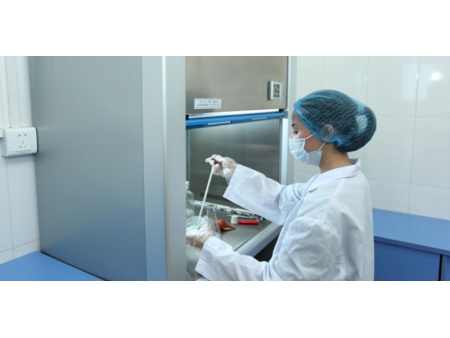

Youjie is equipped with professional clean workshops to produce residential and industrial air filters and strictly control the purifier production process. The qualified rate of the core components of the product reaches more than 98%. Youjie passed ISO9001-2008 quality management system certification in May 2010 and recertified according to ISO 9001:2015 quality management system certification in 2017.

Two non-separator air filter production lines with widths of 600mm and 1200mm, respectively. The maximum width of produced filter element can be up to 1220mm, folding height can be adjusted between 25-100mm to meet the different customization needs of customers.

One 600mm and two 1200mm wide paper folding machines to process 10-100mm folding height air filter replacement.

Youjie owns advanced testing equipment to test every aspect of air purification products. Mainly including:

- Purchased activated carbon inspection instrument for iodine detection of activated carbon.

- Wind tunnel test line for CS-6800 filter material and filter products can test the efficiency and resistance of both raw materials and the filter under the rated air volume.

- Standard 30m3 CADR value test chamber with US TSI-8130 test instrument and PPM htV-m formaldehyde tester to test clean air delivery rate (CADR) and formaldehyde removal rate.

- Youjie has a high-efficiency filter testing station and other testing equipment to test the filtration efficiency of different types of filters.

We strictly comply with international standards for production and testing. The qualified rate of products manufactured can reach 99%. We can provide the filtration efficiency, resistance and CADR value of the filter materials to the customer when the filter is shipped to ensure that it meets their requirements.

In order to reassure our customers, we welcome customers to carry out product quality testing and then confirm shipment before the product leaves the factory.

Before delivery, we will use different sizes pallets to package according to the product size, quantity, and shipping requirements. The pallets are insect-proof and products are wrapped in plastic sheets to prevent moisture, ensuring that the products reach their destination safely and intact.

Optional shipping methods include FBA, third-party overseas warehouse, FOB, EXW and domestic self-delivery. Customers can choose the suitable shipping method according to their own needs.

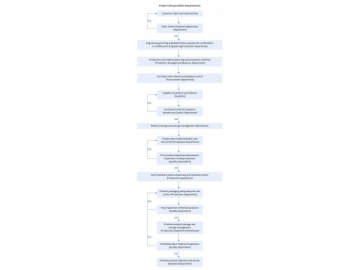

The production cycle of custom filtration is generally 7-15 days. The complete process is as follows.