Steel Pipe Protective Coating (Anti-Corrosion Coating)

Request a Quote

We offer specialized coating services including 3PE (Polyethylene), 2PE, and FBE (Fusion Bond Epoxy) coatings to ensure optimal corrosion resistance in your steel pipes. Each method is tailored to meet specific environmental and usage requirements.

Steel pipe anti-corrosion coating

Available anti-corrosion coating processes

Based on your specific needs, we can recommend the most suitable anti-corrosion process for your steel pipes.

- 3PE coating: Involves applying three layers to the steel pipe: an epoxy powder inner layer (FBE), an adhesive middle layer (AD), and a polyethylene outer layer. This combination creates an anti-corrosion layer with high resistance to corrosion, low water absorption, and excellent low-temperature performance. Ideal for buried pipelines in the petroleum industry, 3PE coatings can last 30-50 years without corrosion.

- 2PE Coating: Consists of two layers: an adhesive inner layer (AD) and a polyethylene outer layer. This method is more cost-effective but offers slightly less corrosion resistance compared to 3PE, making it suitable for less demanding environments such as water supply and drainage systems.

- FBE Coating: Applies a fusion-bonded epoxy thermosetting powder coating to the pipe surface, providing excellent impact and bending resistance. It can withstand high and low temperatures, making it ideal for underwater pipeline applications.

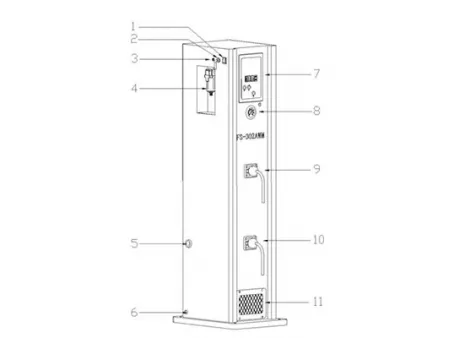

Steel pipe anti-corrosion coating procedure

- Prior to coating, we perform rust removal, degreasing, and phosphating to ensure the steel pipe substrate is in optimal condition.

- During the coating process, we precisely control the thickness of the anti-corrosion layer to guarantee effective performance and longevity.

- We monitor temperature, humidity, and dust levels to ensure optimal adhesion of the coating.

- Drying and curing times are adjusted in real-time based on environmental conditions, material state, and coating thickness.

- Each finished product undergoes technical evaluation to ensure it meets our high standards.

- Before transport, the pipes are carefully packaged to prevent damage to the coating.

Our comprehensive anti-corrosion services ensure your steel pipes are well-protected, reliable, and ready for their specific applications in steel industry.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos