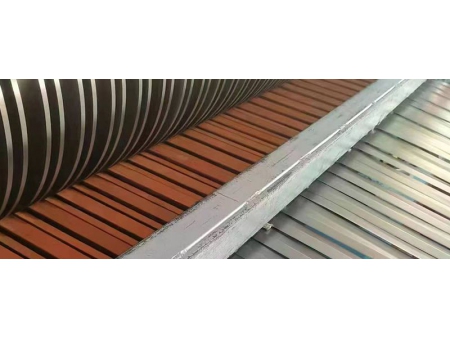

Steel Industry

Ultra-hard material developed and manufactured by Funik is widely used in the steel (ferrous metal) industry. The reliability of steel products is guaranteed by a stable manufacturing process. Funik's CBN cutting tools are used for hot and cold rolling of wires and cables, and is also used in the forging of steel members and tools. We continue to work with our partners to develop specialized cutting solutions to meet their strict requirements for metal forming.

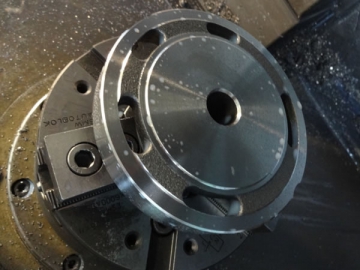

Work piece: all kinds of rollers

Material: high-speed steel, tungsten carbide, etc.

Hardness: HSD80-88

Process: heavy roughing

Original cutting tool: carbide cutting tools

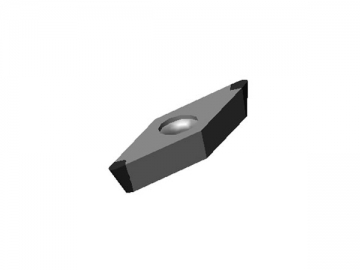

Current cutting tool: Funik's FBN9000 series

Efficiency comparison: 1:8

Life comparison: 1:10

About the Customer

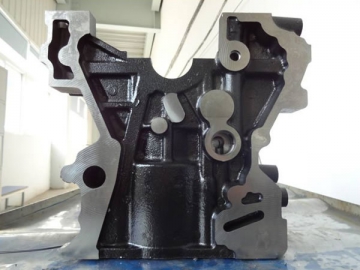

This customer is a steel company in Shandong, China. The customer mainly works to process high-speed steel rollers with a hardness of 80-90HSD, high boron steel, and tungsten carbide rollers. The production duty is very heavy, and without the proper cutting tools, operators can't work faster, which led to production trouble.

Customer Feedback

From the moment we used Funik's CBN cutting tools, we took a step above and beyond the others for proficiently processing high speed steel, high boron steel, and tungsten carbide rollers. As we master high hardness roller processing technology, we use rollers with various hardness levels for different applications, including multi-line split rolling technology. Taking the Φ12 thread four-cut rolling for example, after using this technology, our daily output increased from 1800t/d (cast iron roller) to 2600t/d (high hardness roller). Compared with three-cut split rolling, the four cut added another 100 million dollars to our annual benefits.

Work piece: hot strip mill, medium and heavy plate mill, cold strip mill, large steel mill, universal mill

Material: High NiCr, high Cr, high-Cr, high speed steels, etc.

Hardness: HSD82~93

Process: heavy roughing

Original cutting tool: Foreign coating alloy tool

Current cutting tool: Funik FBN6100 / 3500 Series

Efficiency comparison: 01:06

Life comparison: 01:08

About the Customer

Located in Xingtai, Hebei, the customer has an annual production capacity of 15,000 tons of rollers. The main products are frames and rollers for hot strip mills, and heavy plate mills, cold strip mills, large steel mills, and universal mills. The processing requires special techniques, which have to deal with a strong resistance that is 1.5-2.5 times that of hardened steel with the same hardness. In addition, the material is extremely hard to process. It is difficult to cut, which results in wearing, chipping and crushing of tool chips.

Customer Feedback

High speed steel cutting tools failed in processing the rollers and carbide cutting tools were barely satisfactory. Our original cutting tools have an angle of 5-10º, a cutting depth of 3mm, and a speed of 2-3 rpm. The wearing loss was fast, and the processing efficiency was low, leading to a waste of labor and damage to the equipment. Funik's cutting tools gives us new processing ideas. After years of studying CNB applications, we increased our cutting efficiency by more than 6 times what we had been doing. The actual efficiency of the roller is increased about 3 times what it was previously.