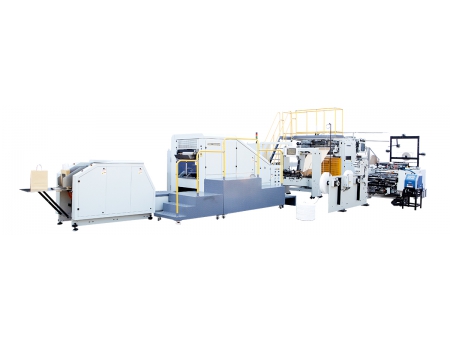

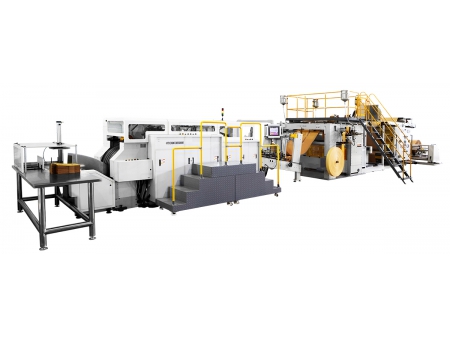

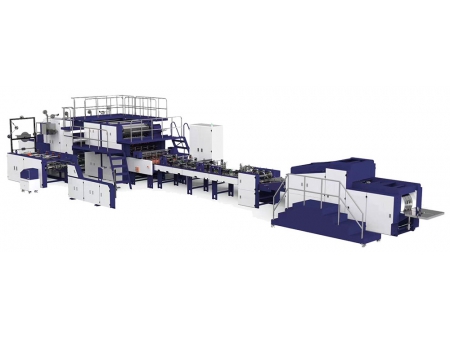

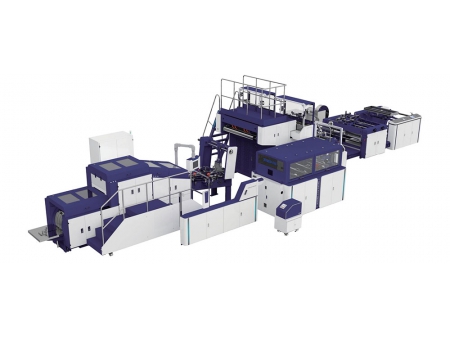

SBH330B/450B-TH Fully Automatic Roll Fed Flat Handle Paper Bag Machine

The fully automatic roll fed flat handle paper bag machine uses roll paper and roll paper handles as the raw material, and can carry out flat handle manufacturing, handle patching, tube forming, tube cutting, bottom forming, and compaction output in one continuous operation. It is especially suitable for large scale production of bags for food packaging and clothing. It also features a fully automatic production.

A flat handle (internal) paper bag has the same weight capacity as that of a twisted handle bag, and is relatively inexpensive to manufacture. The flat handle inside the bag significantly reduces the packing case size and the cost. Machine operation is simple and efficient, lending to its popularity on the market today.

-

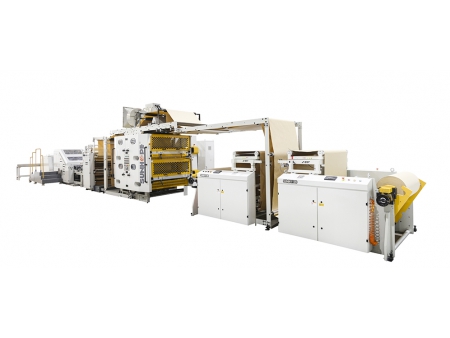

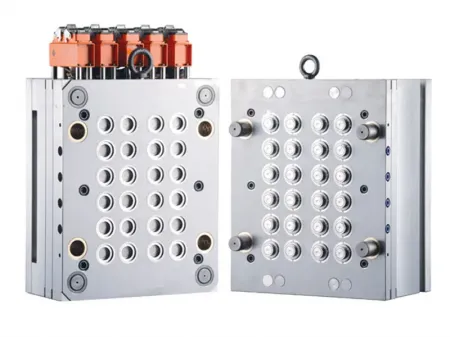

Bottom Forming Drum with Vacuum Assist

Bottom Forming Drum with Vacuum Assist -

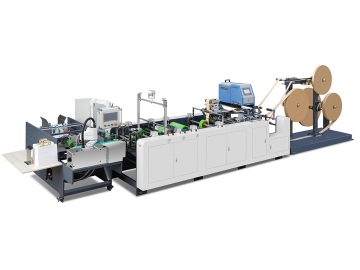

Flat Handle Unit

Flat Handle Unit -

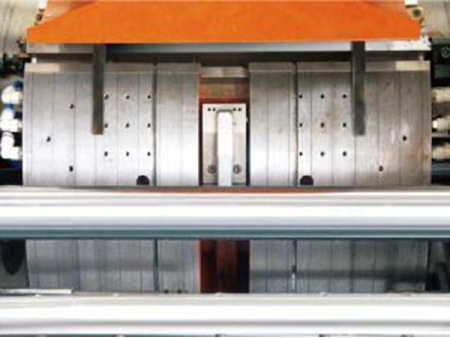

Servo Motorized Plate Device, Adjust the Face Width & Gusset Size Automatically.

Servo Motorized Plate Device, Adjust the Face Width & Gusset Size Automatically.

-

Model:

SBH330-508TH - Paper Thickness (gsm):

- 45-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 180-330/190-330; 120-330(★)

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 160

-

Model:

SBH330B-508TH - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 180-330/190-330; 150-330(★)

- Bag Bottom Size (mm):

- 70-180

- Max. Speed (bags/min):

- 160

-

Model:

SBH330BPro-508TH - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 180-330/190-330; 150-330(★)

- Bag Bottom Size (mm):

- 90-180

- Max. Speed (bags/min):

- 160

-

Model:

SBH450B-518TH - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 368-762

- Bag Face Width (mm):

- 240-450;200-450(★)

- Bag Bottom Size (mm):

- 90-205

- Max. Speed (bags/min):

- 130

-

Model:

SBH450C-518TH - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 240-450

- Bag Face Width (mm):

- 240-450;200-450(★)

- Bag Bottom Size (mm):

- 120-260

- Max. Speed (bags/min):

- 130

| Technical Info | | | | | |

| Paper Roll Width (mm) | 550-1050 | 550-1050 | 570-1050 | 690-1310 | 750-1310 |

| 405-1050(★) | 465-1050(★) | 505-1050(★) | 610-1310(★) | 690-1310(★) | |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 |

| Paper Thickness (gsm) | 45-180 | 50-180 | 50-180 | 70-180 | 70-180 |

| Tube Cut Off Length (mm) | 280-540 | 280-540 | 280-540 | 368-762 | 368-762 |

| Bag Face Width (mm) | 180-330/190-330 | 180-330/190-330 | 180-330/190-330 | 240-450 | 240-450 |

| 120-330(★) | 150-330(★) | 150-330(★) | 200-450(★) | 200-450(★) | |

| Bag Bottom Size (mm) | 70-150 | 70-180 | 90-180 | 90-205 | 120-260 |

| Flat Handle Height (A) (mm) | 75 | 75 | 75 | 100 | 100 |

| Handle Patching Width (B) (mm) | 52 | 52 | 52 | 52 | 52 |

| Handle Patching Length (C) (mm) | 160 | 160 | 160 | 170 | 170 |

| Internal Flat Handle Pitch (D) (mm) | 100 | 100 | 100 | 109 | 109 |

| Internal Flat Handle Width (E) (mm) | 12/16 | 12/16 | 12/16 | 12/16 | 12/16 |

| Internal Flat Handle Paper Roll Width (mm) | 78-85/95 | 78-85/95 | 78-85/95 | 95 | 95 |

| Internal Flat Handle Paper Thickness (gsm) | 70-80 | 70-80 | 70-80 | 80-100 | 80-100 |

| Internal Flat Handle Paper Roll Diameter (mm) | 1200 | 1200 | 1200 | 1200 | 1200 |

| Handle Paper Patch Roll Diameter (mm) | 1200 | 1200 | 1200 | 1200 | 1200 |

| Handle Paper Patch Roll Width (mm) | 160 | 160 | 160 | 170 | 170 |

| Handle Paper Patch Thickness (gsm) | 80-100 | 80-100 | 80-100 | 80-100 | 80-100 |

| Max. Speed (bags/min) | 160 | 160 | 160 | 130 | 130 |

| Total Power (kW) | 29.6 | 32 | 32 | 31 | 31 |

| Machine Weight (kg) | 23000 | 23000 | 23000 | 25000 | 25000 |

| Machine Size (L×W×H)(m) | 14.85×4.2×2.8 | 14.85×4.2×2.8 | 14.85×4.2×2.8 | 16.1×4.5×2.8 | 16.1×4.5×2.8 |

| Three Types of Bottom Seal | yes | yes | yes | yes(Two) | yes(Two) |

| Servo Lip Cut Device | yes | yes | yes | option | option |

| 1-4 Colors Flexo Printer Unit | yes | yes | yes | yes | yes |

| Servo Patch Unit | yes | yes | yes | yes | yes |

| DLO2 TWO Ply Unit | yes | yes | yes | yes | yes |

Note: "★" stands for No Handle.

- The servo adjustable former automatically adjusts the face width & gusset size, significantly reducing the debugging time.

- The drum is equipped with a vacuum assist for better control during bag bottom formation.

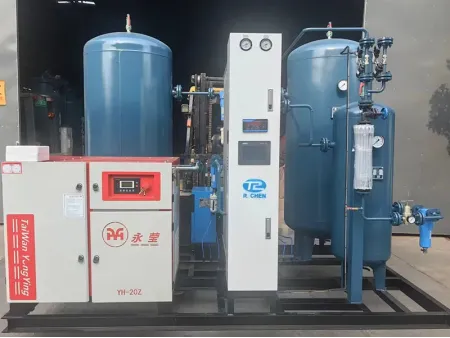

- The bag making machine is equipped with a Mitsubishi electric control system and Mitsubishi motion controller (CPU) in order to achieve a high speed and high precision, as well as motion control and a production flow test. With a touch screen display, the operation functions are clear.

- Equipped with a German BST automatic WEB guiding system, this machine can reduce waste and improve efficiency.

- It is also equipped with an automatic lubricating oil system.