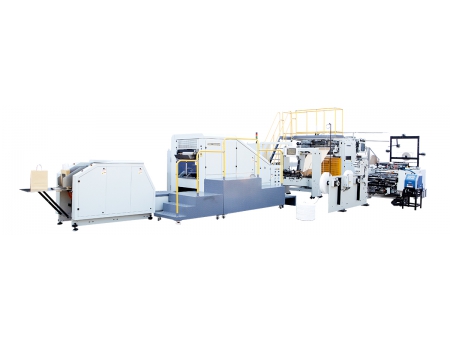

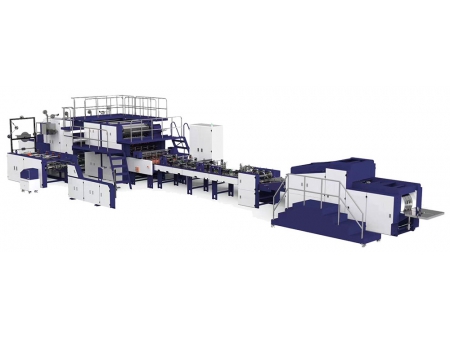

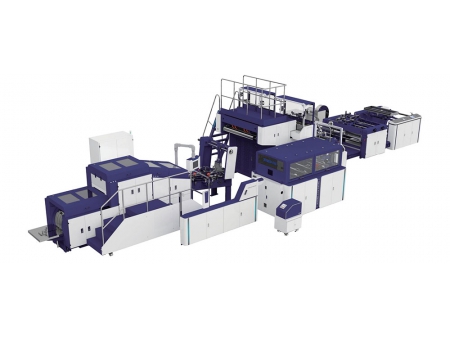

SBH550T/550TB-TH Automatic Roll Fed Internal Flat Handle Paper Bag Machine

This fully automated roll-fed machine is specifically designed for producing internal flat handle paper bags, processing raw materials such as roll paper and roll paper handles in a seamless, continuous operation. This includes internal flat handle manufacturing, handle patching, tube formation, tube cutting, bottom forming, and compaction output, all in one streamlined process. It is particularly well-suited for high-volume production in the food and apparel sectors, offering a truly automated production solution.

Internal flat handle bags provide the same carrying capacity as twisted handle bags but at a significantly lower cost for handle production. The internal handle also reduces packaging size and costs, enhancing overall efficiency. The machine's one-stop and productive operation makes it highly sought after in the market.

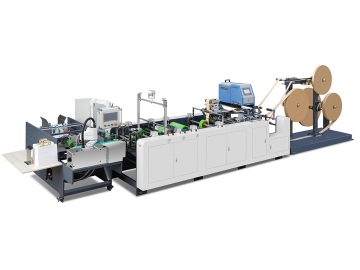

Flat Handle Unit

Flat Handle Unit

-

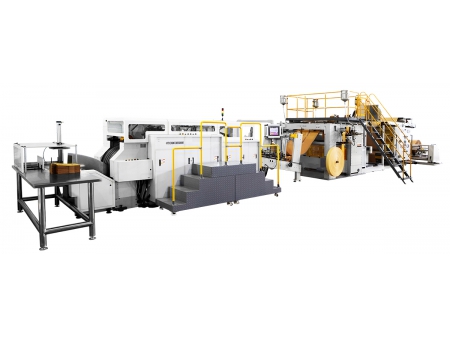

Model:

SBH550T-518TH - Paper Thickness (gsm):

- 80-150

- Tube Cut Off Length (mm):

- 360-770

- Bag Face Width (mm):

- 240-540; 220-540(★)

- Bag Bottom Size (mm):

- 80-230

- Max. Speed (bags/min):

- 130

-

Model:

SBH550TB-518TH - Paper Thickness (gsm):

- 80-150

- Tube Cut Off Length (mm):

- 360-770

- Bag Face Width (mm):

- 240-540; 220-540(★)

- Bag Bottom Size (mm):

- 100-280

- Max. Speed (bags/min):

- 130

| Model | | |

| Paper Roll Width (mm) | 670-1510 | 710-1510 |

| 630-1510(★) | 670-1510(★) | |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Ø76 | Ø76 |

| Paper Thickness (gsm) | 80-150 | 80-150 |

| Tube Cut Off Length (mm) | 360-770 | 360-770 |

| Bag Face Width (mm) | 240-540 | 240-540 |

| 220-540(★) | 220-540(★) | |

| Bag Bottom Size (mm) | 80-230 | 100-280 |

| Flat Handle Height (A) (mm) | 100 | 100 |

| Handle Patching Width (B) (mm) | 52 | 52 |

| Handle Patching Length (C) (mm) | 170 | 170 |

| Flat Handle Pitch (D) (mm) | 109 | 109 |

| Flat Handle Width (E) (mm) | 16 | 16 |

| Flat Handle Paper Roll Width (mm) | 95 | 95 |

| Flat Handle Paper Thickness (gsm) | 80-100 | 80-100 |

| Flat Handle Paper Roll Diameter (mm) | 1200 | 1200 |

| Handle Paper Patch Roll Diameter (mm) | 1200 | 1200 |

| Handle Paper Patch Roll Width (mm) | 170 | 170 |

| Handle Paper Patch Thickness (gsm) | 80-100 | 80-100 |

| Max. Speed (bags/min) | 130 | 130 |

| Total Power (kW) | 36.3 | 36.3 |

| Machine Weight (kg) | 27000 | 27000 |

| Machine Size (L×W×H) (m) | 18.3×5.5×2.8 | 18.3×5.5×2.8 |

| Three Types of Bottom Seal | yes (one) | yes (one) |

| Servo Lip Cut Device | no | no |

| 1-4 Colors Flexo Printing Unit | yes | yes |

| Servo Patching Unit | yes | yes |

| DL02 TWO Ply Unit | yes | yes |

Note: "★" stands for No Handle.

- Comes a servo-adjustable former for automatic adjustments of face width and side gussets, significantly reducing setup time for different bag specifications.

- Incorporates a vacuum-assisted drum to ensure better control and precision during the bag bottom formation process.

- Utilizes a sophisticated Mitsubishi electric control system and motion controller (CPU) for high-speed, high-precision motion control and production flow testing, complemented by a clear and user-friendly touch screen display.

- Equipped with a German BST automatic web guiding system to minimize waste and maximize efficiency.

- Includes an automatic lubricating system for consistent machine maintenance and longevity.

- The internal handle is applied using a single ply of paper with water-based glue, offering the versatility of being either folded inside the bag or displayed standing up.

- Offers 2-4 color flexo printing options, significantly reducing manufacturing costs and enhancing production efficiency.

- Features an optional automatic counting and paper bag stacking system, reducing labor intensity and streamlining the collection process.