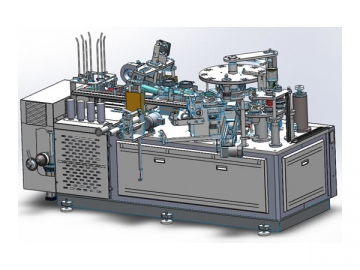

DEBAO-600S-SY Paper Cup Making Machine

This product has been discontinued and removed from our shelves.

Product Features

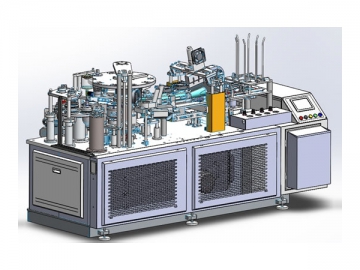

DEBAO-600-SY paper cup making machine forms paper cups for two times by two rotary plates, it is an updated product on the basis of the single plate paper cup machine. It adopts indexing mechanism, gear drive, and vertical axis to ensure the transmission accuracy. Oil spraying method and lubricating oil can reduce the abrasion of machine parts. The first step of paper cup edge curling adopts internal rotary forming method, which can improve paper forming strength. The second step of it adopts heating method, which features of beautiful appearance and stable size.

The paper cup making process is controlled by PLC, optical eye monitoring system is adopted to improve machine performance, safety and stability, servo control system is used to control feeding, so that it the paper cup forming machine operates stably, achieves automatic stop caused by failure, reduces labor intensity of workers. This paper cup maker has the functions of automatic paper feeding, sealing, conveying, heating, knurling, rolling, detecting, discharging, counting, etc. It is suitable for making paper cups with height of 50-135mm.

Our paper cup making machine is widely used in advertising paper cups, milk tea paper cups, disposable paper cup, coffee paper cup, etc.

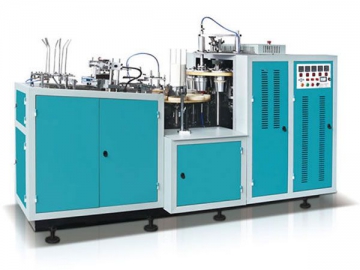

Technical Parameters| Model | DEBAO-600S-SY ( Aluminium alloy shelf by optional ) | |

| Weight | 3500kg | |

| Machine packing size | 3030x1520x2250mm | |

| Cup holder packing size | 1290x570x2100mm | |

| Power supply | Rated power: three-phase 380V, 18KW Actual power: three-phase 380V, 8-9KW | |

| Air source | 0.5-0.8MPa, 0.4cube/min | |

| Production capacity | 90-100pcs/min | |

| Paper type | Single PE/double PE | |

| Paper weight | 200-380g / ㎡ | |

| Paper cup size | (A) φ60-95mm | (B) 70-180mm |

| (C) φ45-65mm | (D) 5-12mm | |

Vertical axis adopts gear drive, cylindrical cam optimizes internal layout, all of these can ensure the transmission accuracy of this paper cup making machine, improve the synchronization performance, so as to achieve the coordination of the stroke, and avoid component damaged.

The paper cup making process is controlled by PLC, optical eye monitoring system is adopted, servo control system is used to control feeding the cup bottom, if there is no cup wall, the system will not convoy the cup bottom.

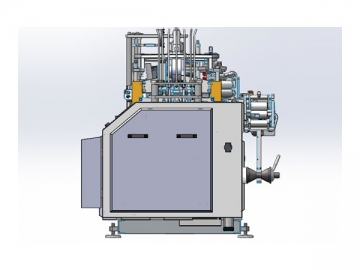

This high speed paper cup machine is designed with box type structure, oil spray and oil lubrication can reduce wear and tear, and heat effectively, so that the machine achieves rapid operation.

Swiss Leister heater is used to glue paper cup wall and bottom. The cup bottom is conveyed into the mould for heating and then cup wall, which can improve the heating effect.

The first step of paper cup edge curling adopts internal rotary forming method, which can improve paper forming strength. The second step of it adopts heating method, which features of beautiful appearance and stable size.

All electrical components are from OMRON and Schneider. The control system adopts PLC programmable controller and touch screen human-machine interface.

Machine Packaging and Transportation High Speed Automatic Paper Cup Forming Machine (140-160 pcs/min, 1-16oz Paper Cup, Coffer Cup Maker, Water Paper Cup Making Machine)

papercup-machines.com

High Speed Automatic Paper Cup Forming Machine (140-160 pcs/min, 1-16oz Paper Cup, Coffer Cup Maker, Water Paper Cup Making Machine)

papercup-machines.com