Innovative production of lithium-ion batteries

The production of high energy density electrode materials is the basis of lithium battery production. The electrode material’s particle size and particle size distribution directly affect battery capacity and energy density. Electrode material grinding improves the machinability due to an enhanced ion and electron conductivity as the particle size is reduced.

Backed by professional wet grinding equipment and extensive industry knowledge, Sanxing Feirong offers solutions for key steps in lithium battery production.

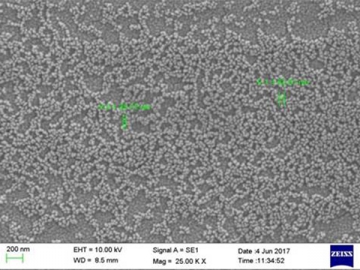

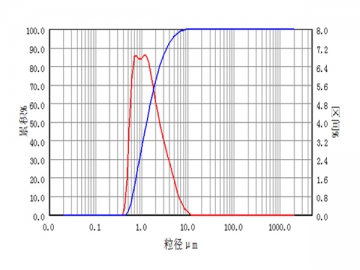

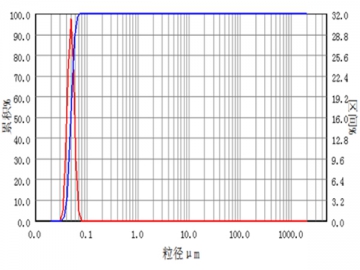

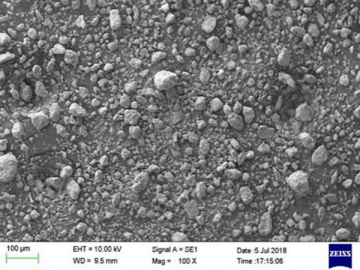

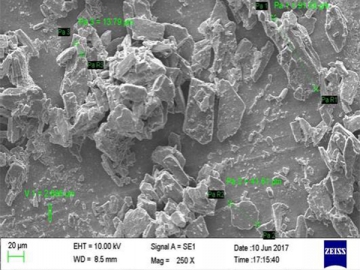

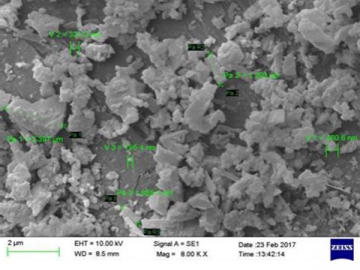

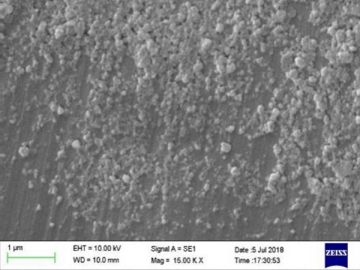

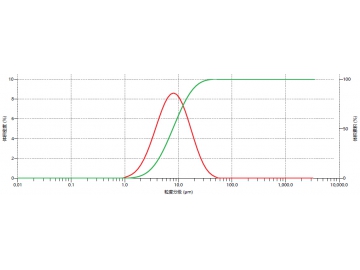

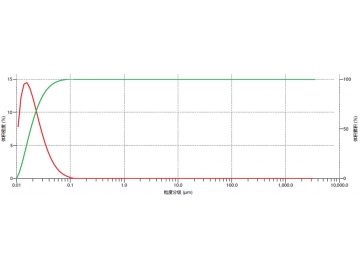

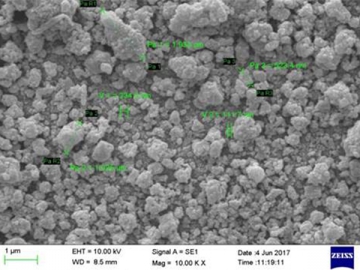

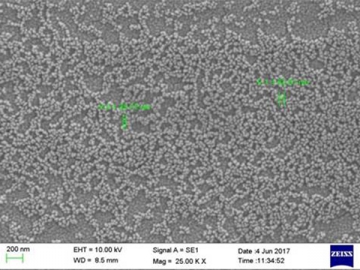

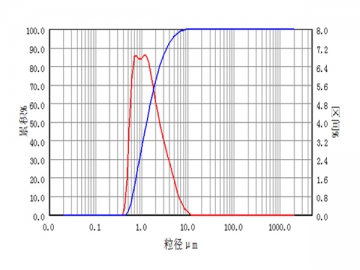

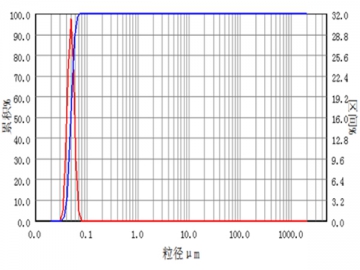

Shown here are the ultrafine grinding results of lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4) using our bead mills. It is clearly demonstrated that our grinding mills carried out an ultra-fine grinding that significantly reduced particle size and ensured a more uniform distribution, effectively improving lithium battery performance and offering better economic benefits.

Please do not hesitate to contact us for more information.

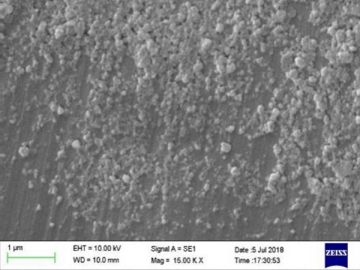

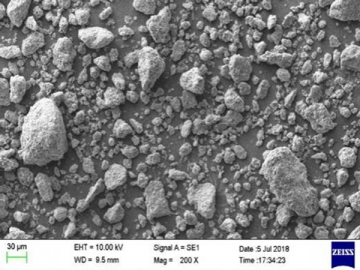

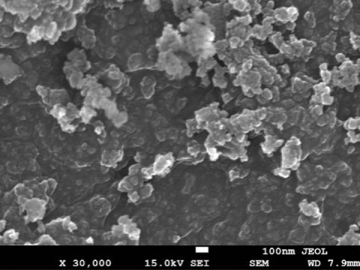

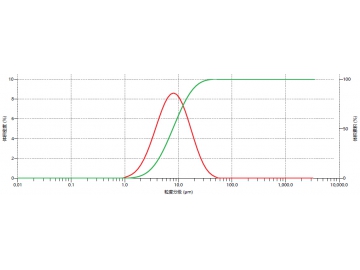

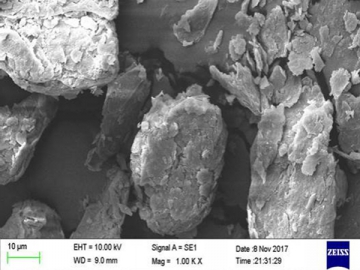

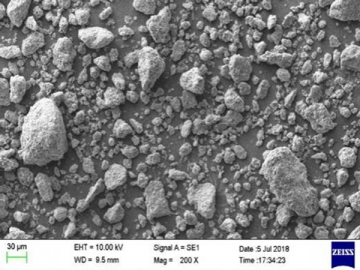

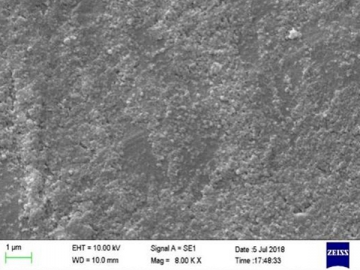

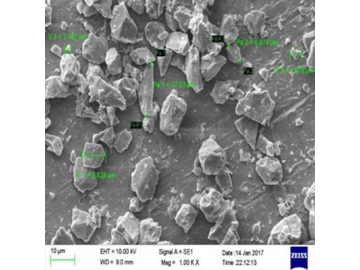

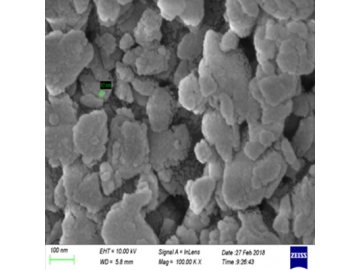

Grinding of lithium cobalt oxide (LiCoO2) - Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 20.60 | 0.09 |

| D90(μm) | 80.20 | 0.13 |

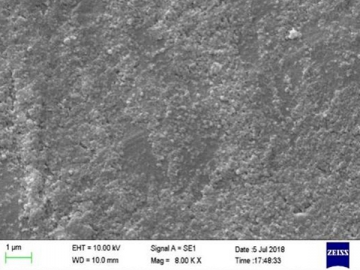

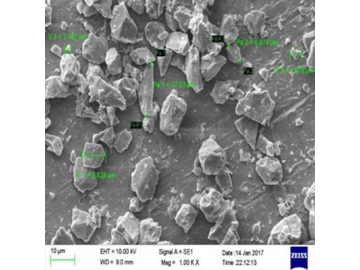

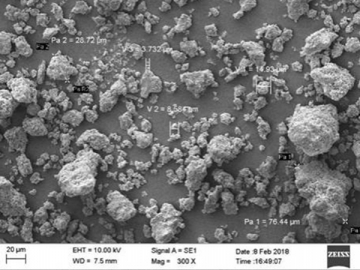

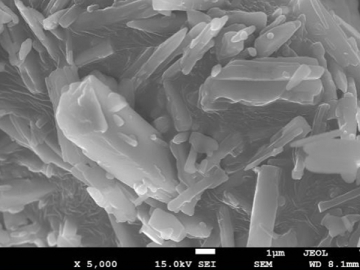

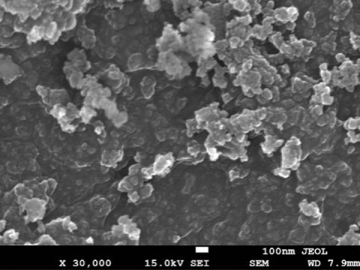

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 10.00 | 0.08 |

| D90(μm) | 80.00 | 0.15 |

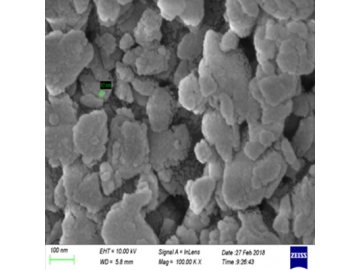

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 4.00 | 0.06 |

| D90(μm) | 12.00 | 0.12 |

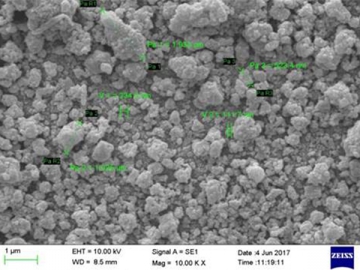

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 10.00 | 0.03 |

| D90(μm) | 18.00 | 0.05 |

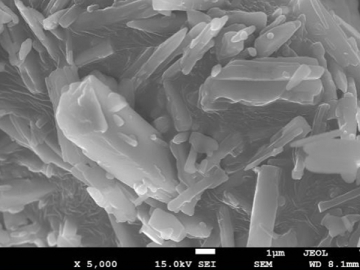

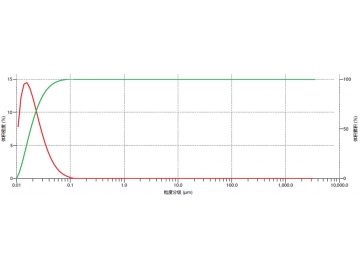

- Before grinding

- Before grinding

- Before grinding

- After grinding

| Characterized size | Feed | Product |

| D50(μm) | 1.5 | 0.05 |

| D90(μm) | 6.2 | 0.06 |