Lithium Carbonate Drying System

Industrial Drying Solutions

We provide industrial drying solutions for the production of battery grade lithium carbonate (Li₂CO₃)

Drying Conditions and Considerations for Li₂CO₃

The drying process is adapted to the characteristics of lithium salts and the strict purity standards required for battery applications. For high-purity Li₂CO₃, moisture content typically ranges from 10% to 15% before drying and needs to be reduced to between 0.2% and 0.4% after drying. In addition, battery-grade materials must meet low magnetic impurity standards, usually below 20 ppb. These levels are important to ensure the stability and performance of lithium-ion batteries.

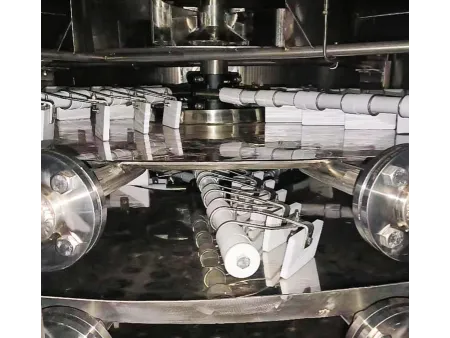

To meet these strict requirements, we offer rotary tray dryers with customized material contact surfaces. In cases where magnetic contamination must be minimized, main parts such as distributor trays, drying plates, and inlet/outlet areas can be made of titanium instead of stainless steel. Even when using 304 or 316L stainless steel materials, our rotary tray dryer ensures that the increase in magnetic material content after drying does not exceed 20 ppb. We have supplied customized systems to multiple lithium battery material manufacturers, helping them meet moisture and purity standards while adapting the equipment to their specific production processes.

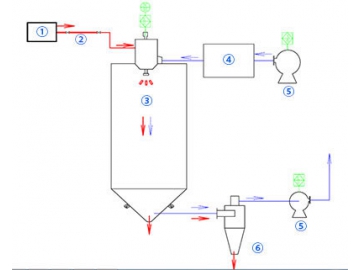

- Our drying systems are designed for stable, continuous operation with high energy efficiency, often reaching over 85%.

- Most of the powder generated during drying can be recovered, over 99%, which helps maintain a clean and safe working environment.

- Each tray in the drying unit can be set to heat or cool independently. This makes it possible to dry material in the upper section and cool it in the lower section, all within the same drying system, while keeping temperature control precise and consistent.

- For materials that contain small lumps or clumps, we can add a crushing mechanism inside the dryer to break them into finer particles. This improves heat transfer, speeds up the drying process, and helps keep the product more uniform.

- A material leveling device is installed at the top of the dryer to ensure that the product is evenly distributed across the drying trays. This prevents material from falling directly from the feeder onto the trays, which could damage the rake arms and rake blade or cause uneven buildup during operation.

- In high-capacity drying setups, we also apply design upgrades to prevent wet material from falling straight to the base of the unit, which could otherwise result in inconsistent drying and moisture issues in the final product.

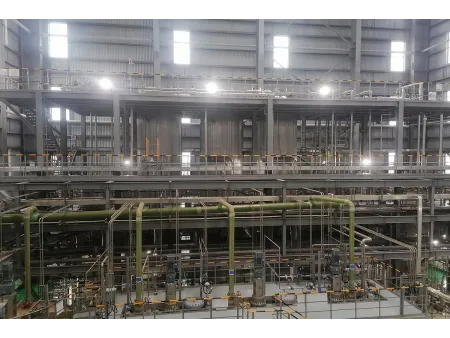

A Jiangxi-based factory using a rotary tray dryer