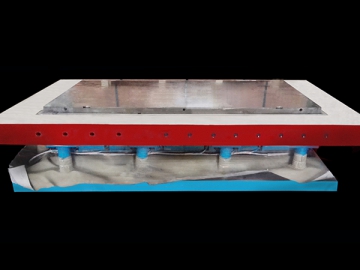

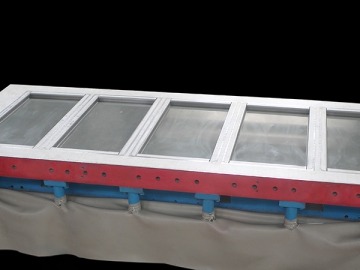

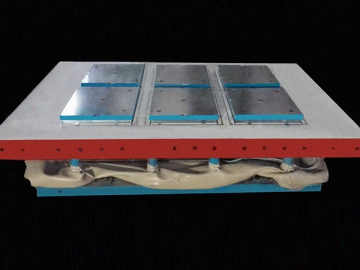

Mold Assembly for Polishing Tiles

Mold assemblies for polishing tiles can be manufactured to produce tiles that meet various customer specifications for both large and small tiles. We have successfully developed a variety of specifications for the exhaust mold, which effectively solves problems large ceramic tiles are prone to, especially during the green body layering stage. This increases the number of press/minute stamping processes. In addition, the polished tile mold assembly can ensure a thicker material structure for added durability. A spreading and sticking wear resistant ceramic is applied to the machine’s frame surface for machine protection, as well as a magnetic block heat treatment process, and a dust cover to place over the machine when not in use. Improving the configurations of the mold assembly increases the service life, wear resistance and stability.