Decorative Insulated Wall Sandwich Panels

Architectural insulated panels for exterior walls

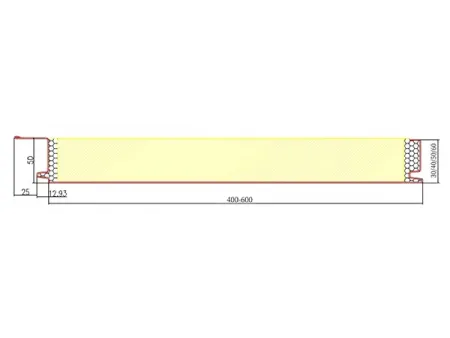

- Effective cover width: 400mm/500mm/600mm

- Length: 1m-12m (customizable)

- Sandwich panel thickness: 30mm/40mm/50mm/60mm

- Metal sheet thickness: 0.3mm-0.7mm

- Core material: Rigid polyurethane (PUR/PU), mineral wool, glass wool

- Metal sheet material: Galvalume steel sheet, titanium zinc sheet, Al-Mg-Mn alloy sheet

Architectural insulated panels for exterior walls feature a multi-layer structure that combines strength, efficiency, and design flexibility. The outer surface is a 0.6 mm aluminum sheet with a protective coating that preserves color and provides strong resistance against harsh weather, available in both smooth and embossed finishes to match different façade designs. The insulation core is made of rigid polyurethane foam, ensuring good thermal performance and energy efficiency, while the inner layer consists of a 0.06 mm aluminum skin that further enhances heat protection.

Suitable for a wide range of projects, including industrial facilities, residential housing, commercial buildings, schools, hospitals, hotels, office buildings, large public spaces, prefabricated structures, and renovation of existing façades.

| Effective cover width | 400mm/500mm/600mm |

| Length | 1m-12m (customizable) |

| Sandwich panel thickness | 30mm/40mm/50mm/60mm |

| Structure | Metal sheet insulation core aluminum film |

| Metal sheet material | Galvalume steel sheet, titanium zinc sheet, Al-Mg-Mn alloy sheet |

| Metal sheet thickness | 0.3mm-0.7mm |

| Metal sheet suppliers | Baosteel, BlueScope, Yieh Phui, Wah Tung, Alliance Steel, etc. |

| Core material | Rigid polyurethane (PUR/PU), mineral wool, glass wool |

| Color | Standard color custom color |

| Surface finish | Wavy, embossed, smooth |

| Surface coating | PE/HDP/PVDF, etc. |

| Lifespan | At least 30 years |

| Applications | Architectural roof and wall cladding |

| Remarks | 1. Professional installation guidance is provided to help ensure accurate and efficient assembly 2. Complete sets of accessories are supplied 3. Panels can be customized according to client requirements, offering flexibility for different projects |

| Core material | Polyisocyanurate (PIR) | Polyurethane (PUR/PU) | Glass wool | Mineral wool |

| Density | 30-60kg/m³ | 30~45kg/m³ | 48~64kg/m³ | 100~120kg/m³ |

| Thermal conductivity | 0.024kcal/mh℃ | 0.018kcal/mh℃ | 0.042kcal/mh℃ | 1.4kcal/mh℃ |

| Fire rating | Class B1 | Class B1 | Class B2 | Class B1 |

- Panels can be customized in different colors and finishes, including smooth and embossed surfaces, to achieve a wide range of façade design effects.

- The multi-layer structure delivers reliable protection against moisture, water, fire, noise, and heat transfer, improving both comfort and safety.

- A weather-resistant and self-cleaning outer surface ensures long-term durability while protecting the panels from corrosion.

- Lightweight construction makes handling and installation easier, speeding up the process and lowering overall project costs.

- Panels are installed with a dry-hanging keel system that eliminates the need for wet construction methods, making the process safer and more reliable.

- The design creates an additional air cavity between the panel and the wall, providing a double layer of thermal insulation for improved energy efficiency.