Your trusted partner for bagging and palletizing systems

BZR Series

Heated-bar bag closing machine for sealing and stitching of PE-lined woven bags

The woven bag heat sealing and stitching machine is designed for woven bags (including laminated woven bags) and supports heat sealing of the inner PE liner while applying a crepe-paper tape to the outer surface. It can also be used for other packaging materials with similar structures. The system is commonly applied in chemical, food, and building materials industries where reliable sealing and stitching performance is required.

The woven bag heat sealing and stitching machine is designed for PE-lined woven bags and similar packaging materials. It uses a two-stage sealing process: the inner liner is heat-sealed first, followed by the application of a hot-melt adhesive tape on the outer layer. This structure improves leak prevention, especially for powder products, and enhances resistance to dust, moisture, and handling during transport.

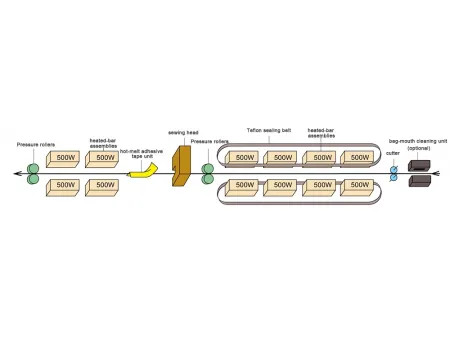

Bag mouth cleaning (optional) → Bag-top trimming (cutting) → Inner liner heat sealing (4 heated-bar assemblies; Teflon sealing belt prevents direct contact between the heated bar and the bag surface, ensuring clean sealing and avoiding adhesion) → Pressure rollers for sealing → Sewing of the outer woven layer → Application of hot-melt adhesive tape → Heat sealing (2 heated-bar assemblies) → Final pressure-roller consolidation

| Model | BZR-1 |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×12 |

| Sealing power | 0.55kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW |

| Total power | 7.5kW |

| Machine dimensions (L×W×H) | 3750×1090×2052mm |

| Machine weight | Approx. 850kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Woven (film laminated) bags (inner PE liner heat sealing, outer hot-melt tape) |

| Bag requirements |

|

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

This woven bag heat sealing machine applies inner-liner heat sealing followed by an outer crepe-paper tape, which helps prevent material leakage and provides strong dust-proof and moisture-resistant performance.

Bag mouth cleaning (optional) → cutter: bag-mouth trimming → inner bag heat sealing (4 sets of heated bars; the PTFE sealing belt prevents direct contact between the heated block and the bag surface to avoid sticking) → pressure rollers for compression → crepe-paper tape → bag sewing machine: outer-bag stitching

| Model | BZR-2 |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×8 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 1.6kW |

| Total power | 6.55kW |

| Machine dimensions (L×W×H) | 3153×1090×2052mm |

| Machine weight | Approx. 650kg |

| Sewing head model | DS-11 |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Woven (film laminated) bags (inner PE liner heat sealing, outer crepe-paper tape) |

| Bag requirements |

|

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

This heated-bar sealing and folding system carries out inner-bag heat sealing followed by bag-top inward or outward folding before stitching. The combined process helps prevent material leakage and provides strong resistance to dust and moisture, making it suitable for demanding industrial packaging environments.

Bag-top cleaning (optional) → inner-bag heat sealing (4 heated-bar units; PTFE sealing belt prevents direct contact between the heated bars and the bag surface) → pressure-roller sealing → bag-top folding (inward or outward) → sewing of the outer woven bag

| Model | BZR-3 |

| Sealing speed | 10–15m/min |

| Heating power | 0.5kW×8 |

| Sealing power | 0.55kW |

| Sewing power | 0.4kW |

| Total power | Approx. 5kW |

| Machine dimensions (L×W×H) | 2900×1090×2052mm |

| Machine weight | Approx. 650kg |

| Sewing head model | GS-11 |

| Folding method | Outward folding |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Woven (film laminated) bags (inner PE liner heat sealing, outer) |

| Bag requirements |

|

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.