TJ550 Copper Bus Bar & Profile Line

Continuous Extrusion Machine for Copper Busbar

This product has been discontinued and removed from our shelves.

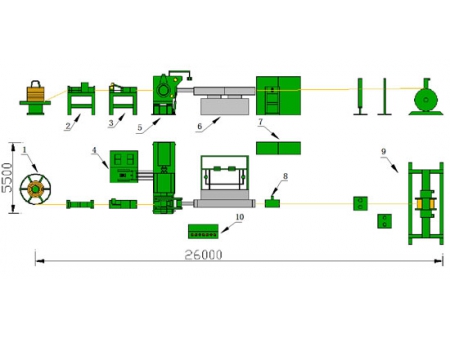

The TJ550 continuous rotary extrusion line is designed to form copper busbars with maximum width of 260mm. By exchanging the extrusion die, the copper extrusion equipment can also be applied to produce copper alloy conductors and other types of copper products with sectional area between 380 and 5000mm2. These extruded busbars are regularly found in power distribution cabinets, electrified railway systems, and more.

Our continuous rotary extrusion line adopts copper rod as feedstock. The maximum rod diameter is 22mm. Available with copper rod payoff machine and extruded busbar take-up machine, our range of continuous rotary extrusion machinery has high efficiency, with maximum output up to 2500kg/h. The touch screen design for its electrical control system ensures optimized operation convenience.

| Machine Specifications | |

| Continuous Extrusion Machine Model | TJ550 |

| Power of Main Motor | 450kW |

| Production Capacity | 800~2500 kg/h |

| Flash Amount | ≤5-8% |

| Feedstock Specifications | |

| Copper Rod Diameter | Φ22 mm |

| Diameter Tolerance | ±0.2mm |

| Extruded Product Specifications | |

| Busbar Sectional Area Range | 380~5000mm2 |

| Max. Busbar Width | 260mm |

| Copper Rod Payoff Machine | 1 pcs |

| Copper Rod Straightener | 1 pcs |

| Copper Rod Cutting Machine | 1 pcs |

| Continuous Rotary Extrusion Equipment | 1 pcs |

| Cooling and Oxidation Prevention System | 1 pcs |

| Meter Counter | 1 pcs |

| Gantry Type Busbar Take-up Machine | 1 set |

| Electrical Control System (with Touch Screen) | 1 set |

Continuous Extrusion Process, Copper Continuous Extrusion Machine, Bus Bar Extrusion Line, Continuous Rotary Extrusion Equipment Manufacturer