Connector Vision Inspection Machine

Optical sorting machine with 7 CCD cameras for the dimensional measurement and defect detection of connectors and pin headers

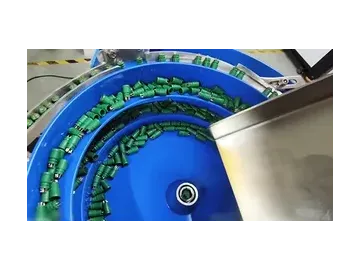

The connector vision inspection machine combines an automatic elevator feeder with vibration bowl feeding to ensure efficient and consistent part handling. It is equipped with AI-powered visual inspection software and 7 high-resolution CCD industrial cameras for precise and comprehensive defect detection.

This system identifies surface issues such as missing pins, pin misalignment, burrs, breakage, poor molding, and chipped corners. It achieves a detection speed of 150 pcs/min with ±0.01 mm measurement precision. Upon request, the machine can also integrate with an automatic packaging unit for counting, labeling, and packaging, streamlining your inspection and post-processing workflow.

Get in touch to see how this solution can bring speed and precision to your connector inspection operations.

| General | Power | 1.8 kW | |

| Air pressure | 0.4-0.6Mpa,air inlet pipe Ø16mm | ||

| Machine dimensions | 1100(L)×1700(W)×1800(H)mm | ||

| Machine weight | 350kg | ||

| Working conditions | Less than 90% RH | ||

| Visual inspection | Inspection speed | Design speed: 80-3000 pcs/min | |

| CDD Camera | Image sensor | Basler (German) | |

| Resolution | 2560×1920,1280×1024 | ||

| Inspection accuracy | ±0.01mm | ||

| Lens | Optical lens | Custom lens | |

| Depth of field (DoF) | 0.2-3mm | ||

| Light source | AOI light source | ||

| Feeding | Precision belt feed system | Precision belt is made from special conductive material through integrated forming process,ensuring high accuracy (customized) | |