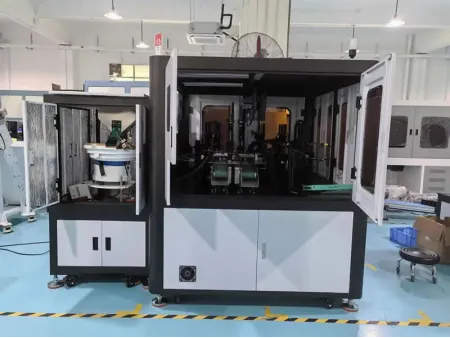

Screw Vision Inspection Machine

Optical sorting machine with 3 CCD cameras for the measurement and inspection of cross-head screws

Designed for precision inspection of cross-head screws, the screw vision inspection machine combines vibration bowl feeding, intelligent visual detection software, and three high-resolution CCD cameras. This system ensures consistent part orientation, efficient processing, and accurate results during high-speed production.

This optical sorting machine measures essential dimensions like outer diameter and height, and detects surface defects such as cross-slot residue, missing teeth, and broken corners. With a detection speed of up to 500 pcs/min and precision of ±0.01 mm, the screw vision inspection machine helps you maintain tight quality control while improving production efficiency.

Reach out to learn how this advanced solution can improve your fastener inspection process.

| General | Power | 1.8 kW | |

| Air pressure | 0.4-0.6Mpa,air inlet pipe Ø16mm | ||

| Machine dimensions | 1100(L)×1700(W)×1800(H)mm | ||

| Machine weight | 350kg | ||

| Working conditions | Less than 90% RH | ||

| Visual inspection | Inspection speed | Design speed: 80-3000 pcs/min | |

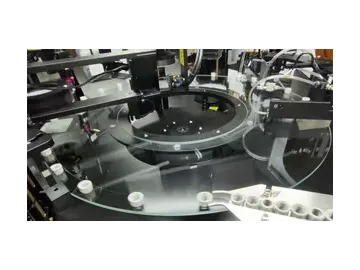

| CDD Camera | Image sensor | Basler (German) | |

| Resolution | 2560×1920,1280×1024 | ||

| Inspection accuracy | ±0.01mm | ||

| Lens | Optical lens | Custom lens | |

| Depth of field (DoF) | 0.2-3mm | ||

| Light source | AOI light source | ||

| Feeding | Precision belt feed system | Precision belt is made from special conductive material through integrated forming process,ensuring high accuracy (customized) | |

- Thread

- Sharpness

- Height

- Head Defect

- Cross Recess Blocking

- Head OD