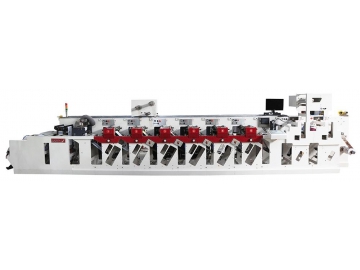

F5 Flexo Printing Press

The F5 flexographic press is a highly automated, multi-substrate flexographic press that is capable of printing up to 12 colors, and is designed for printing and post processing of various labels, including films, shrink sleeves, wrap-around labels, sheets of hoses, adhesive label and flexible packaging materials.

This flexographic printing press was designed in 2015, and features a better performance and the cylinder can be replaced quickly and easily. Job changing takes roughly 20 minutes, with only about 25 meters of material waste. When the web is changed, material loss is even less, at 5 meters.

- Lable on adhesive tape

- Tag label

- Shrinkable film label

- Box label

Suitable material: PVC film, PP film, PET film, aluminum foil, paper, adhesive tape,sheets of hoses, shrink sleev.

Thickness of material: 0.0012-0.4mm

| Speed | 150m/min |

| Max web width | 330/430 mm |

| Repeat length | 229mm-502 mm |

| Max. unwind diameter | 760 and/or 1000 mm |

| Max. units | 760 and/or 1000 mm |

| Max. rewind diameter | 12Units |

| UV curing power | 400 w/inch |

1. Servo drive

Built-in dual servo driven system offers more capabilities, including an automatic alignment, automatic registration and secondary registration, makes the operation much easier, stable and eliminates bar marking effectively.

2. Short web path design

Short web path design for only 1.3 meter within a printing station can reduce material waste during start up and printing job change. Paper path reduced to 15 meters because flexo printing press equipped with eight colors printing plus two die stations.

3. Lock ink cassette by air cylinder

Lock ink cassette by air cylinder, Which makes operation easier and more quickly change. Separated Anilox with in pan, as well as avoids the removal of the anilox roll when changing the ink.

4. Pre-registration and auto-registration

F5 flexo printing press includes Pre-registration and auto-registration which improves both efficiency and cost savings.

5. Nip device on waste rewind

Nip device on waste rewind to guarantee waste matrix to be unbreakable during high speed production which increases effectiveness and yield of production since we can push matrix width to the minimum required by the cutting edge of knife.

6. Movable rail

Movable rail makes the flexo press earier extend more options, including a delam/relam device, UV rotary screen, turn bar, die cut, screen print, laminating and cold foil.

7. Advanced tension control device

With an advanced tension control device, the lables on 12 micron film, sticker and paper board can all be printed using the F5 flexo printing press. Change of operating speed will not affect registration. There is no waste during jogging and all the way up to production speed.

8. Drying

Drying options include hot air and UV drying (or LED UV). UV drying equipment is from Europe, and self-designed hot air drying enables solid printing to be dried at 40℃ at 150 m/min

9. The control system can record and recall process parameters of different materials.

10. The water cooled UV curing system, ensures materials maintain a suitable temperature when UV drying, and is suitable for the processing of thermal deformation materials.

11. It is equipped with an internet access function so that all devices can be remotely maintained and upgraded.

Index

flexo printing machines, flexographic printing, printing press, printing equipment