Coating

Request a Quote

White Bottom Coating

Types: aluminum tubes, aluminum cans

Applications: printing coating of the aluminum tube and the aluminum can

- The white bottom coating is applied in the production lines whose production speed ranges from 60/min to 220/min. You can choose coatings of different types for different production lines.

- The coating has great occlusion and can be blended into different colors.

- The standard curing condition is 160℃×6min. But we can conduct minute adjustment according to the requirements of different production lines.

- The coating meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

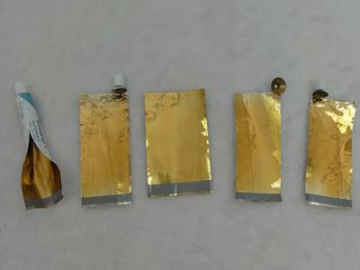

Internal Coating

Types: internal coatings of aluminum tubes and aluminum cans

Applications: printing coatings of the inner surface of the aluminum tubes

Color: gold, beige

- The internal coating has great chemical resistance and is applied in hair dye and medicine.

- The internal coating is applied in the production lines whose production speed ranges from 60/min to 180/min.

- The standard curing condition is 160℃×6min. But we can do minute adjustment according to the requirements of different production lines.

- The coating meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

Tube End Cap Glue

Types: waterborne acrylic resin

Application: the inner surface of the aluminum tube end

- The tube end cap glue kicks in bonding, sealing and leak prevention. It is divided into two types: the surface sticking type and the not sticky type.

- The glue is applied in the production lines whose production speed ranges from 60/min to 180/min.

- The standard curing condition is dry at room temperature. In winter, it can be dried forcibly under low temperature.

- The glue meets with EU 2002/95/EC, USA FDA175.300 and CN GB9685 regulatory compliance.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos