Load Former

With the focus on increasing the productivity for paper machines and corrugated cardboard production lines, Taiyang has designed and manufactured a variety of load former systems for pallet handling needed in the paper and corrugated industry. Our pallet handling systems are specially designed to improve the pallet loads of corrugated material stacking while ensuring the high efficiency and flexibility of pallet distribution.

At Taiyang, we have a team of specialists to help corrugated board plants with appropriate palletizing solutions to integrate their corrugated board and carton packaging systems.

If you have any questions about our palletizers and load former systems, please

The load former system is designed with a focus on enhancing productivity, ensuring the safety of employees, providing a comfortable work environment, and facilitating ease of use. This load former equipment integrates a palletizer, pallet dispenser, and conveyor, making it optimal for efficiently stacking corrugated cardboard boxes, whether strapped or unstrapped, directly from high-speed printing machines, die cutters, or carton packaging equipment.

The innovative "lifting design" eliminates the need for operators to bend, lift, or stretch excessively during the palletizing process, reducing fatigue and the risk of injuries while simultaneously optimizing the productivity and performance of printing, die-cutting, and box-gluing machines.

Advantages

- Quality assurance: The palletizing process eliminates the need to lift paperboard bundles, giving operators more time to inspect the final product for defects. This ensures only quality paperboards are delivered to your customers while maintaining operational efficiency.

- Flexible stacking configurations: Allow operators to palletize cardboard of various sizes and shapes from the RDC (rotary die cutter), FFG (flexo folder gluer), die-cutters, stitchers, and more—into customized stacking patterns and heights as per client requirements. The simple partition-based stacking structure enables operators to efficiently and effectively handle a wide range of cardboard sizes and shapes, ensuring precise and consistent results.

- 100% Electric drive: The load former operates entirely on electric power, offering a smooth, fast, and safe operation that is reliable and efficient. The electric drive design offers a significant reduction in maintenance requirements, ensuring long-term reliability in contrast to the hydraulic drive.

- User-friendly interface: The user-friendly touchscreen interface simplifies operations, allowing users to input the necessary dimensions to palletize paperboard bundles of different sizes with ease.

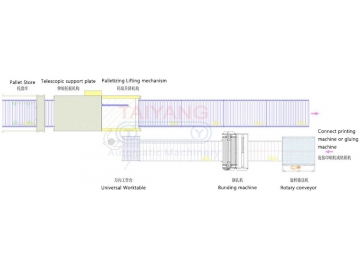

Components of the Load Former System

- Palletizer: the palletizer mainly consists of conveyor lift, stripper plate and powered backstop;

- Pallet Dispenser: to automatically store and release pallets;

- Roller conveyor: to convey pallets and stacks. Pallet centering device is equipped for the roller conveyor;

- Control system: with programmable PLC, pallet specifications, stack width, height and in-feed thickness can be adjusted conveniently by entering parameters.

The semi-automatic load former palletizer is designed to integrate seamlessly with any flexo printer slotter die-cutter or cardboard box production line, enhancing operational efficiency and streamlining production processes. In addition to enhancing productivity, the system is designed to minimize operator fatigue.

The hopper allows forklift or clamp attachments to load an entire pallet stack, ensuring smooth and efficient workflows. When used in conjunction with Taiyang palletizing systems, the pallet dispenser ensures a more reliable and streamlined stacking process, thereby optimizing productivity and operational ease.

- Load Former Palletizer

In 2022, Taiyang supplied a semi-automatic load former system to Papelera del NOA, a leading manufacturer of corrugated paper, cardboard, and cartons. With a production capacity of 6,000 tons of virgin fiber paper per month and 25 million square meters of corrugated board, the company is a key supplier to the citrus and tobacco markets.

The load former palletizer, designed to accommodate 1800L*1800W pallets with a stacking height of up to 2400mm, markedly enhanced palletizing efficiency and equipment performance. The load former system reduced the need for two operators and minimized labor intensity, which demonstrates Taiyang's commitment to delivering operational excellence.

- Semi-Auto Load Former System

SAC, one of Peru's largest packaging manufacturers, is renowned for its strategic foresight in carton packaging production and its robust industry reputation.

In 2021, SAC made a significant investment in a Taiyang semi-automatic load former system, capable of handling pallets ranging from 1200L*1100W to 1900L*1300W with stacking heights of up to 2200mm.

The load former system significantly enhanced palletizing efficiency, reduced labor costs, and minimized employee workload, further solidifying SAC's commitment to innovation and operational excellence.

- One-stop Solution for Load Former System

In 2023, Sovremennaya Upakovka, a leading Russian packaging manufacturer, partnered with Taiyang to implement a fully integrated load former system. Taiyang played a key role in the project, providing comprehensive services from start to finish. These included planning, process design, equipment installation, automation commissioning, and trial production.

The semi-automatic load former system markedly enhanced Sovremennaya Upakovka's stacking efficiency, reduced labor costs, and minimized operator fatigue, exemplifying Taiyang's dedication to providing bespoke, efficient solutions for its clients.

Our load former systems are compatible with flexo folder gluers, rotary die cutters, box gluing machines, stitching machines, and die-cutters.

We offer a standard model (1800*1800) designed for stacks up to 1800L*1800W*2400H. For custom size requirements, please contact us to discuss tailored options.

We´ ll need your factory’s CAD layout and drawings or specifications of your production equipment to evaluate and create a system tailored to your needs.

Standard load former systems take 60 days to deliver. For customized machines, the lead time depends on specific requirements.

Taiyang offers comprehensive after-sales service with experienced personnel and an extensive spare parts inventory:

- Issue Resolution: We provide online guidance within 24 hours of the fault occurring.

- Warranty: 1-year free warranty; lifetime paid services available at competitive rates to ensure reliable and safe equipment performance