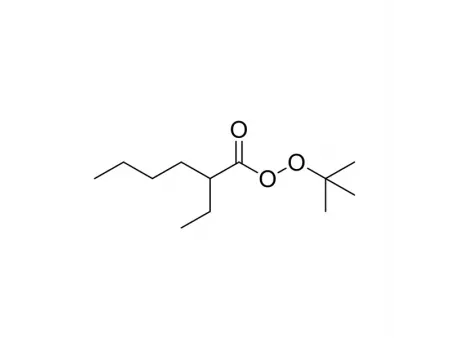

tert-Butyl peroxy 2 ethylhexanoate (TBPEH)

- Chemical Family Organic Peroxide

- Molecular Formula C₁₂H₁₄O₃

- Molecular Weight 216.4

- UN No. 3113

- Transport Hazard Class 5.2

- (organic peroxide, Type C, liquid, subject to temperature control in transport, forbidden for rail and air transport)

Half-Life Period

- 0.1 hour 113℃

- 1 hour 91℃

- 10 hours 72℃

- Theoretical active oxygen content: 7.40%

- Purity: 97% min

- Self-accelerating decomposition temperature (SADT): 35℃

- Hazardous temperature (Tem): 25℃

- Temperature control (Tc): 20℃

- Storage temperature (Ts min/Ts max): -30/20℃

- Activation energy: 124.9kJ/mol

- Appearance: Colorless clear liquid

- TBHP content: 0.1% max

- Inorganic/organic hydrolyzable chloride: 100mg/kg max

- Chromaticity: 20APHA

- Major decomposition products: tert-butyl alcohol, methane, 2-ethyl acid, n-heptane, ethane, carbon dioxide

TBPEH is widely used as an initiator in the polymerization of ethylene and styrene, offering reliable performance in various industrial applications. It also acts as an effective high-temperature curing agent, particularly for unsaturated polyester resins. This chemical compound is known for its consistent initiation capabilities in both polymerization and curing processes, especially when working with high temperatures, making it essential in sectors like plastics, resins, and coatings manufacturing.

- Frequently used as a reliable initiator in both autoclave and tubular processes for ethylene polymerization. It also serves as an initiator for acrylates and methacrylates, functioning within a temperature range of 80-150°C.

- TBPEH demonstrates higher activity than benzoyl peroxide (BPO) in styrene polymerization. It is often used in combination with other peroxides, such as TBPB and TBEC, and is particularly effective in initiating copolymers like ethylene-vinyl acetate (EVA).

- This chemical compound is widely applied as a high-temperature curing agent for unsaturated polyester resins, with curing temperatures between 120-160°C. It’s the preferred choice for curing processes in compression molding (DMC, BMC). TBPEH can also be used at lower temperatures (around 60°C) with cobalt-based accelerators in processes like air-drying paints and filament winding.

-

Packaging

Standard packaging is available in 20 kg polyethylene drums, though customized sizes can be arranged based on customer requests.

-

Validity

When stored according to manufacturer guidelines, TBPEH remains effective for up to three months.

-

Safe Handling

Store in a cool, well-ventilated area, maintaining temperatures below 20°C.

Keep away from open flames, heat sources, and incompatible chemicals such as acids, reducing agents, and flammable materials.

Ensure storage areas are equipped with explosion-proof lighting, with external switches for added safety.

Handle with care, using appropriate protective equipment to prevent damage to the packaging.

Consult the Material Safety Data Sheet (MSDS) for complete handling instructions.