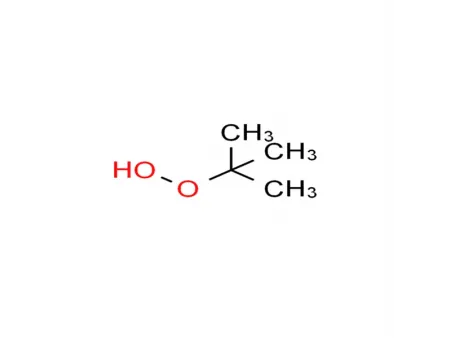

tert-Butyl hydroperoxide (TBHP)

- Chemical Family Organic Peroxide

- Molecular Formula C₄H₁₀O₂

- Molecular Weight 90

- UN No. 3109

- Road Transport (ADR) 5.2

- Rail Transport (RID) 5.2

- Sea Transport (IMDG) 5.2

Half-Life Period

(measured in chlorobenzene solution)

- 0.1 hour 207℃

- 1 hour 185℃

- 10 hours 164℃

- Theoretical active oxygen content: 17.78%

- Self-accelerating decomposition temperature (SADT): 80℃

- Hazardous temperature (Tem): 75℃

- Storage temperature (Ts min/Ts max): 0/40℃

- Appearance: Colorless liquid.

- Major decomposition products: methane, acetone, tert-butyl alcohol

tert-Butyl hydroperoxide (TBHP) is known for its role in organic synthesis, where it acts as an effective oxidizing agent, converting olefins into alcohols, ketones, or aldehydes. Its versatility extends to other compounds like amines, sulfides, and selenides. In the industrial sector, TBHP is used in the polymerization process, serving as a free radical initiator for materials like acrylates and silicone monomers. This leads to the creation of various polymer products. Additionally, TBHP is used in surface treatments, rubber additives, and as a cross-linking agent for polymers. Its role also spans into the biomedical field, where it is utilized as a reagent in DNA sequencing, contributing to advancements in biological research and diagnostics.

- Used in emulsion polymerization, aqueous-phase polymerization, curing, and graft polymerization. In many cases, it outperforms alternatives like persulfates, cumene hydroperoxide, and benzoyl peroxide.

- Widely applied as a polymerization initiator for styrene, acrylic, and methacrylic compounds.

- Serves as a vulcanizing agent for natural rubber and can be used to enhance the cetane number in diesel fuel.

- Acts as an important intermediate in organic synthesis, playing a key role in various chemical reactions.

- Known for its high selectivity and efficiency in epoxidation processes, making it a crucial oxidizing agent in many applications.

-

Packaging

The standard packaging consists of polyethylene drums with a net weight of 20 kg or 180 kg. Smaller packaging options are available upon request to meet specific customer needs.

-

Storage

Keep the packaging sealed and store in a well-ventilated area with a maximum storage temperature of 40°C. Avoid contact with reducing agents such as amines, acids, bases, and heavy metal compounds (such as accelerators and metallic soaps). Repackaging and usage inside the storage facility are strictly prohibited.

-

Safe Handling

Keep away from fire, open flames, and heat sources.

Avoid contact with reducing agents (e.g., amines), acids, bases, and heavy metal compounds (e.g., accelerators, metallic soaps).

Refer to the product's Safety Data Sheet (MSDS) for detailed safety instructions.

Since its foundation in 1966, LAAP has established itself as China's first manufacturer of organic peroxides used for polymerization, curing, and crosslinking.

For more information about our products, please contact our experts. We look forward to hearing from you.

Please be as specific as possible around the product or application information you are looking for to get the best possible support.