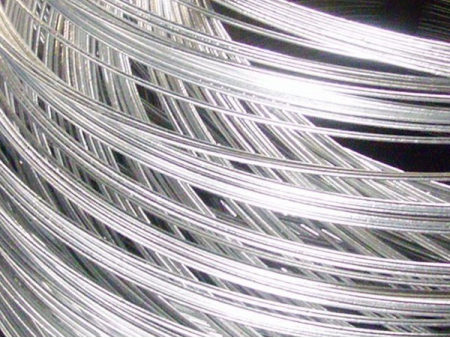

Galfan Coated Steel Wire

Using several of our own technologies and the advanced galvanizing technology——Sendzimir Galfan coating technique, GONGDA has built a hot-dip galvanizing line with an annual production capacity of more than 10,000 tons. The Galfan coated steel wire has smooth surface, great adhesion performance, desirable mechanical performance, and stable product quality. Actually, as reliable zinc coated steel wire supplier, we are one of the three Chinese companies that have the right to use the Galfan trademark. GONGDA has been in a great relationship with the Galfan technology center.

Parameter

- Product: Galfan coated steel wire and stranded wire

- Wire diameter: 1.0~4.0mm

- Coating thickness: 40~350g/m2

- Cohesiveness: wrapping test (1×dia.)

- Coating uniformity: 60% or above

- Good corrosion protection

Thanks to the addition of aluminum, Galfan coatings develop a dense, protective aluminum oxide film that effectively slows down zinc oxidation and increases the corrosion potential. At the initial stage, corrosion resistance benefits from the combined action of zinc’s sacrificial protection and aluminum’s barrier effect. Over time, the self-passivating layer of aluminum oxide becomes the main protective mechanism. This combination gives the coating a corrosion resistance approximately two to three times greater than that of conventional pure zinc coatings. - Enhanced mechanical properties

The 5% aluminum content refines the microstructure, replacing the brittle delta phase with a tougher Fe₂Al₅ phase. This change reduces the transition layer’s thickness and improves ductility. As a result, the coating achieves stronger adhesion, better flexibility, and higher resistance to cracking or deformation during handling and processing compared to typical hot-dip galvanizing. - Lower processing temperature

Galfan coatings are applied at temperatures between 420–430 °C, which are notably lower than the 450–460 °C range required for traditional galvanizing. This helps maintain the mechanical properties of the steel substrate and extends the operational lifespan of the galvanizing equipment.

Weight loss comparison of coating in industrial applications

Weight loss comparison of coating in marine applications

Weight loss comparison of coating in rural applications