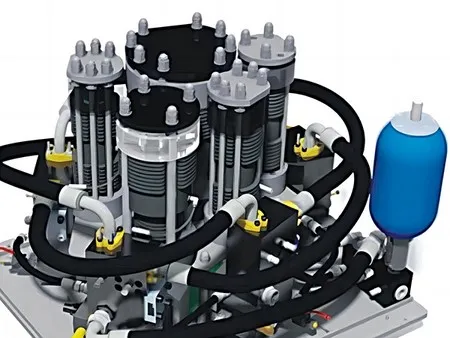

Hydrogen Ionic Compressor

To address the issues of mechanical wear and significant thermal losses at low power inherent in traditional mechanical compressors, the ionic liquid compressor was developed. This type of compressor works by replacing traditional pistons or diaphragms with a special ionic liquid that compresses the gas. In a hydrogen ionic compressor, hydrogen is injected into the cylinder, where it is compressed by the ionic liquid that circulates within and remains virtually incompressible. This liquid does not dissolve or contaminate the hydrogen, thus forming an effective seal within the cylinder while also providing excellent lubrication and cooling properties. This ensures efficiency and safety during compression, effectively solving sealing and contamination issues associated with hydraulic pistons. It is compact, efficient, pollution-free, capable of high pressure, and large displacement, making it particularly suitable for the pressurization needs of special gases like hydrogen.

- Discharge pressure

45-100MPa

- Flow

90-340Nm³/h

Hydrogen ionic compressors are extensively used in pharmaceuticals, metallurgy, chemical, and energy sectors. For example, in pharmaceuticals, ionic liquid heat exchangers, separators, and membranes are used for separation, purification, and controlling the uniformity of ionic liquid qualities in manufacturing processes. They are also employed in the chemical industry for transferring gases from a low to a high-pressure physical state. Moreover, due to innovative sealing technologies, these compressors offer pollution-free and leak-free operations, meeting the pressurization needs for hazardous, flammable, and explosive gases. They are widely used in hydrogen filling, hydrogen refueling, and chemical synthesis.

Features- Ionic Liquid Lubrication and Cooling: Significantly reduces wear on moving parts.

- Frequent Load Start-Stop Capability: Designed for long-term operation without maintenance.

- Simple and Compact Structure: Occupies a small footprint.

- Lacks Wearable Components: Such as piston rings and packings found in piston compressors.

- Advanced Compression Abilities: Features multi-stage compression, extremely large displacement, and 100% zero leakage.

- Xinran hydrogen ionic compressor does not produce exhaust gases during compression, nor does it require a cooling system, avoiding secondary pollution. This makes it more environmentally friendly, economical, and reliable than traditional compressors.

- Due to the good flow properties of the ionic liquid, the compressor operates with minimal noise, enhancing its durability.

- The hydrogen ionic compressor performs highly efficient and precise gas compression, saving energy and reducing operational costs.

- The low vapor pressure of the ionic liquid and the low solubility of hydrogen make the compression process safer.

- The compressor uses a crankshaft connecting rod structure, where the piston's reciprocating motion compresses the gas. It optimizes cylinder structure to balance forces across various stages, reducing vibrations and achieving more than three stages of compression, with a total compression ratio of up to 400 times.

- One of the most innovative features is in the piston sealing area—Xinran has developed a non-volatile, non-decomposing cyclic ionic liquid driven by a dedicated plunger pump. This liquid provides sealing, lubrication, and cooling to the piston rings, in conjunction with sealing components to achieve 100% zero leakage in the compression chamber.