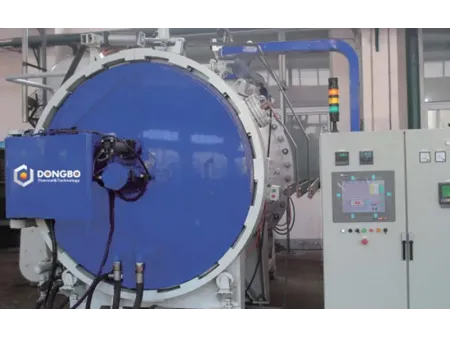

Vacuum Hydrogen Furnace

Vacuum Heat Treatment Furnace

The vacuum hydrogen furnace is used for heat treatment processes such as vacuum high-temperature brazing, vacuum aging, hydrogen reduction, and vacuum sintering of various materials, including high-speed steel, high-alloy tool steels, carburizing steel, precision bearings, oil pump and nozzle components, and precision machinery parts. It is also suitable for hydrogen-charged sintering heat treatment of non-ferrous metals and magnetic materials, ensuring high-purity heat treatment and optimal material performance.

| Model | |||||

| Effective internal dimensions (mm) | 600×400×400 | 700×500×500 | 900×600×600 | 1200×600×600 | 1200×900×900 |

| Max. load capacity (kg) | 200 | 300 | 500 | 800 | 1200 |

| Heating power (kW) | 65/90 | 85/120 | 120/160 | 160/210 | 240/300 |

| Max. temperature (℃) | 1320 | 1320 | 1320 | 1320 | 1320 |

| Ultimate vacuum level (Pa) | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ | 4×10⁻¹/4×10⁻⁴ |

| Temperature uniformity (℃) | ±5 | ±5 | ±5 | ±5 | ±5 |

| Max. cooling gas pressure (bar) | 1.99 | 1.99 | 1.99 | 1.99 | 1.99 |

| Pressure rise rate (Pa/h) | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 | 0.5/0.27 |

The above parameters are for the standard vacuum dehydroxylation hydrogen furnace. We can provide customized, non-standard designs and manufacturing to meet specific customer requirements, such as achieving an ultimate vacuum level of 10⁻⁴ Pa or higher and a pressure rise rate better than 0.1 Pa/h.

The furnace incorporates proprietary process control technologies, including pulse hydrogen charging under negative pressure, which optimizes gas usage while maintaining safety, and dynamic constant-pressure hydrogen charging under negative pressure, ensuring consistent process stability during reduction, brazing, sintering, and aging. These advanced methods not only help to reduce energy consumption but also enhance operational safety and process precision, making the system highly reliable for complex industrial applications.