PCD/PCBN Cutting Tools

PCD Cutting Tool, PCBN Cutting Tool

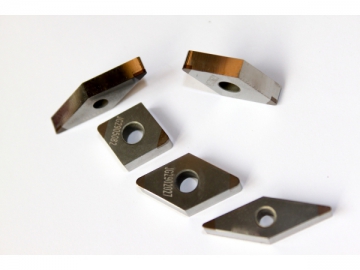

1. PCD Cutting Tool

Description

PCD blanks not only have the advantagesof diamonds, such as high hardness, high abrasive resistance, high thermal conductivity, low frictioncoefficient and low expansion coefficient, but also the features of hardenedalloy, including good strength and toughness. The PCD cutting tool is one of the mostimportant new cutting tools. It can realize high speed cutting, hard material cutting and precisionprocessing. The PCD cutting tool meets the requirements of environmentalprotection.

Features

1) The hardness of PCD reaches 8,000HV, which is 80 to 120 times the hardness of tungsten carbide.

2) The heat conduction coefficient of PCD is 1.5 to 9 times that of tungsten carbide. It is even higher than thecoefficient of PCBN and copper. Thecoefficient of PCD reaches 700W/mK. The PCDcutting tool can conduct heat at fast speed.

3) The friction coefficient of PCD is only 0.1 to 0.3, while that of tungsten carbide is 0.4 to 1. The PCD cutting tool can reduce the cutting force.

4) The thermal expansion coefficient of PCD is 0.9×10-6 to 1.18×10-6, which isonly one fifth that of alloy. The PCDcutting tool features small thermal deformation and high processing precision.

5) The affinity between PCD cutting tool and different materials, including nonferrous metal andnonmetal material is small. The cuttingswill not attach to the cutting tool during cutting.

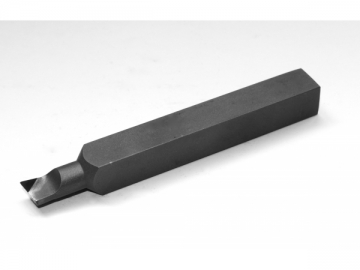

2. PCBN Cutting Tool

Description

PCBN blanks have the advantages of highhardness, high thermo stability, high chemical stability, good strength andgood weld ability. The PCBN cuttingtool is one of the most important new type cutting tools. It can realize high speed cutting, hardmaterial cutting, dry cutting, the replacement of grinding with turning, andprecision processing. The PCBN cuttingtool meets the requirements of environmentalprotection.

Features

1) The PCBN cutting tool has high hardness and abrasive resistance. The hardness of PCBN blanks reaches 3,000 to5,000HV, so the PCBN cutting tool has high abrasive resistance. Theabrasive resistance of PCBN cutting tool is 50 times that of tungsten carbide cuttingtool, 30 times that of coating tungsten carbide cutting tool, and 25 times that ofceramic cutting tool.

2) High thermo stability and high heat resistance. The PCBN cutting tool can bear temperature ashigh as 1400 to

3) High chemical stability. The PCBNcutting tool features high oxidation resistance. It still will not be oxidized under thetemperature of

4) Good heat conductivity. The heatconduction coefficient of PCBN material is lower than that of diamonds, but itis higher than that of tungsten carbide.

5) Low friction coefficient. Thefriction coefficient of PCBN is only 0.1 to 0.3, while that of tungsten carbide is0.4 to 0.6.

Application

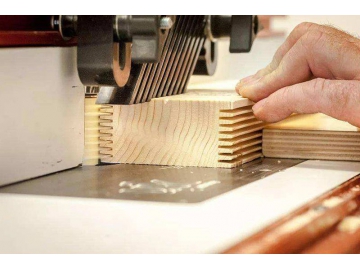

The PCD cutting tool is used in different fields including aviation, car industry, electronics, andthe wood and stone industry. Itapplies to nonferrous metal,tungsten carbide,ceramic, nonmetal and compound materials.

The PCBN cutting tool applies tovarious ferrous metals, such as cast iron, nodular cast iron, pearlite greycast iron, HRC45-68 hardened steel, bearing steel,tungsten carbide, hard roller andsintered alloy.

Technical Specifications

| Parameters Recommended for PCD Cutting Tool | |||

| Work Piece Material | V(m/min) | f (mm/rev) | Ap (mm) |

| Al and Al Alloys | 200~3000 | 0.05~0.5 | 0.05~1.0 |

| Nonmetal Material | 100~500 | 0.05~0.5 | 0.05~1.0 |

| Carbide | 20~30 | 0.05~0.2 | 0.05~1.0 |

| Parameters Recommended for PCBN Cutting Tool | ||||

| Work Piece Material | Hardness | V(m/min) | f (mm/rev) | Ap (mm) |

| Gray Cast Iron | HB170~300 | 500~1500 | 0.1~0.4 | 0.1~1.5 |

| Alloyed Iron | HB240~300 | 150~300 | 0.05~0.4 | 0.1~0.5 |

| Nodular Cast Iron | 100~350 | 200~400 | 0.1~0.4 | 0.1~0.5 |

| P/M Fe-based | HRC55-65 | 50~150 | 0.05~0.4 | 0.05~0.5 |

| Hardened Steel | HRC55~65 | 80~200 | 0.05~0.2 | 0.05~0.2 |

| Heat-resistant Alloys | 110~160 | 50~200 | 0.05~0.2 | 0.05~0.2 |

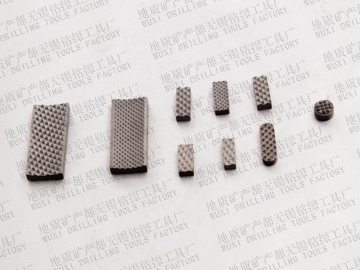

Material

Our PCN blanks and PCBN blanks aremanufactured by world famous companies, such as E6, GE(DI), LIJIN, SMITH,SUMITOMO and TOMEI.

Packaging

The PCD and PCBN cutting tools are packaged in a plastic case/carton.

World is a PCD cutting tool manufacturer and supplier, based in