Information

Do you need cold roll formed light gauge steel framing products for your whole projects? You may need to consider many questions. For example, what applications are they used for, inside or outside, load bearing or non load bearing? This simple guide may help you to choose suitable high quality light gauge steel framing products.

Light gauge steel framing products are generally made of galvanized steel coils or stainless steel coils by cold bending technology. Materials usually determine the applications of products. If used indoors, non-load bearing galvanized steel light gauge frames can enable you to well control procurement cost. And the galvanized protective coating on the surface can produce certain corrosion resistance. For outdoor applications, there are higher demands for wind resistance and corrosion resistance. So we recommend thicker stainless steel light gauge frames which can improve safety coefficient.

NBXF strictly adopts high quality raw materials, including Q195 hot dip galvanized steel, Q235 hot dip galvanized steel, 201 stainless steel and 304 stainless steel. Of course, we can purchase other raw materials according to your demands and produce light gauge steel framing products.

Size selection needs to be considered from many aspects. In drywall framing system, the size of light gauge steel frames is generally determined by wall thickness and gypsum board thickness, and thick gypsum boards should match with large size metal frames. In metal stud ceiling system, 60mm thick load bearing channels are suggested if there are wire lines or other things which need frequent examines on the top. For common decoration or household applications, 50mm thick channels show higher cost performance.

We can produce light gauge steel framing products with maximum thickness of 2mm. And width, depth and length can be flexibly adjusted.

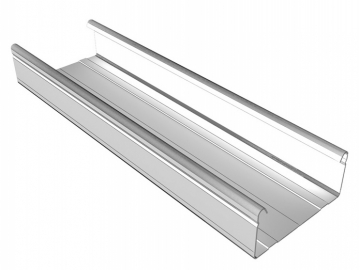

The shapes of light gauge steel frames will directly determine the methods of installation and arrangement, and their architectural mechanics structure stability. U-shaped channels and C-shaped channels are most common used light gauge steel frames and they can be sued for non-load bearing drywall framing systems. U-shaped channels, furring channels and Z-furring channels can be combined together as ceiling systems. Slotted channels and furring channels can be combined as slot type ceiling systems which are more convenient for installation.

With many years of manufacturing experience, we can provide U-shaped channels, C-shaped channels, furring channels, Z-furring channels and profiled steel framing, which can satisfy the demands for most light gauge steel construction structures. Besides, we can also customize more shapes according to your drawings.

Different construction structural systems are usually composed of different shapes of light gauge steel frames and accessories, and they also have different demands for slots and lock pillars. For example, in drywall framing systems, U-shaped channels need punching process, which is convenient for inserting through channels later to form whole drywall framing systems. To get your desired light gauge steel framing products, you need to tell us the applications or directly provide drawings to ensure that our customization products can fully meet your requirements.