Get The Right Advice.

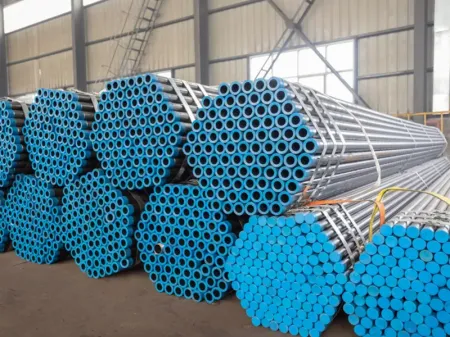

Manufacturing

Our manufacturing facility spans over 100,000 square meters and houses more than 20 production lines, employing a dedicated team of 360 professionals. With an annual production capacity of 500,000 tons, we are well-equipped to meet the demands of the steel pipes and PC strand industry. Our advanced equipment includes automated welding pipe production lines, high-precision cutting machines, and intelligent welding machines, all designed to enhance production efficiency and ensure the highest quality and precision in our welded pipe products.

In addition, we have implemented an intelligent management system for real-time monitoring and data analysis of the production process. This system further boosts our production efficiency and ensures consistent quality and reliability.

With expanding steelmaking capabilities globally, we are equipped to meet the increasing demands of various industries, providing both high-quality products and outstanding service.

ERW Steel Pipe Production Process

- Leveling

- Ends Cutting

- Slitting

- Recoiling

- Coil Ramp

- Uncoiling

- Leveling

- Ends Cutting

- Trimming & Welding

- Coil Accumulator

- Strip Ultrasonic Testing (UT)

- Forming

- High Frequency Welding

- Welding

- Deburring

- Seam Annealing

- Air/Water Cooling

- Sizing (Round Tube)

- Online Ultrasonic Testing (U.S. Test)

- Straightening

- Flying Cut-off

- Flattening Test

- End Finishing

- Hydrostatic Test

- Appearance Inspection

- Offline Ultrasonic Testing (U.S. Test)

- Marking

- Oil Coating

- Packaging & Storage

Spiral Welded Steel Pipe Production Process

- Decoiling

- Welding

- Conveying

- Forming

- Hydrostatic Test

- Cut-Off

- Ultrasonic Testing

- X-ray Inspection

- Marking

- Storage

ERW Galvanized Steel Pipe Production Process

- Incoming Inspection

- Workpiece Loading

- Skimming

- Alkali Washing

- Water Washing

- Pickling

- Water Rinsing

- Soaking

- Tumover & Hanging

- Hot-Dip Galvanizing

- Residual Zinc Removing

- Water Cooling

- Inspection & Trimming

- Quality Control

- Marking

- Storage

- Delivery

Prestressing Steel Strand Production Process

- Surface Treatment

- Wire Rod

- Drawing

- Heat Treatment

- Water Cooling

- Prestressing Steel Wire

- Stranding

- Heat Treatment

- Water Cooling

- Prestressing Steel Strand

- Packaging

- Plastic Sheathing

- Water Cooling

- Unbonded Prestressed Concrete Steel Strand

- Transporation

Quality Assurance

- At RuiTong Steel, we prioritize the selection of raw materials. Through years of collaboration, we have established an ideal supply chain and scientific raw material storage management system, ensuring consistent product quality and efficient production in the steel pipes and PC strand industry.

- We have developed comprehensive production process specifications. Every employee undergoes formal training to master the relevant knowledge, skills, and safety procedures for welding pipe operations. Regular training, technical exchanges, and assessments are conducted to continually improve the skill levels of our technicians, ensuring they adapt to the company's evolving needs.

- We adhere to strict product quality standards. After batch production, our QC personnel conduct sample testing to ensure they meet the specified quality criteria. This testing process guarantees that our steel products consistently meet high standards.

- We welcome third-party inspections and actively collect customer feedback to continuously improve our services and enhance customer satisfaction.