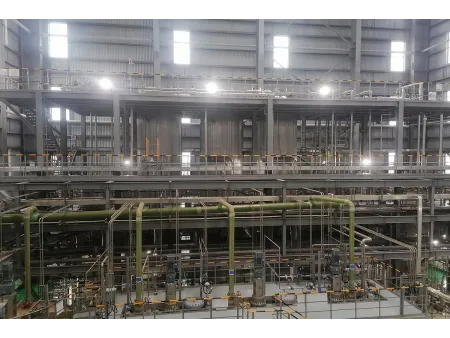

Lithium Hydroxide Cooling Crystallization System

Industrial Cooling Crystallization Solutions

We provide LiOH cooling crystallization solutions for producing mirabilite crystals

The cooling crystallization process for lithium hydroxide is designed to remove sodium sulfate in the form of sodium sulfate decahydrate (mirabilite). It typically follows a two-stage continuous setup. In the first stage, most of the mirabilite is separated using either a two-stage pusher centrifuge or a horizontal scroll-type filtering centrifuge.

The remaining solution then goes through a second cooling stage to extract additional mirabilite through deep cooling. Since the crystal content is lower at this point, separation is performed using a horizontal scroll-type filtering centrifuge. After most of the sodium sulfate crystals are removed, the remaining liquid (mother liquid) moves on to the next stage, while the slurry is recycled back to the first centrifuge for additional processing.

In lithium hydroxide and sodium sulfate solutions, mirabilite (sodium sulfate decahydrate) can be separated through a cooling crystallization system designed for continuous operation. This approach includes several process-specific considerations:

- To allow crystals to grow to a stable and usable size, the crystallizer provides adequate residence time throughout the cycle.

- As the solution cools, it becomes more viscous, and the density difference between the liquid and the crystals is relatively small. A larger settling area is integrated to support more efficient solid-liquid separation under these conditions.

- Crystals formed during continuous cooling crystallization are typically smaller than those from batch systems. As a result, more fine particles remain suspended in the mother liquor, and higher amounts of residual liquid adhere to the crystal surfaces, requiring careful handling during centrifugation.