Lithium Hydroxide Monohydrate Drying System

Industrial Drying Solutions

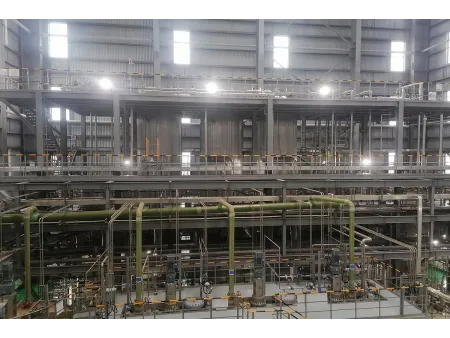

We provide industrial drying solutions for obtaining battery grade lithium hydroxide monohydrate (LiOH•H₂O)

Drying Conditions and Considerations for LiOH•H₂O

Drying lithium hydroxide monohydrate (LiOH•H₂O) requires careful control of temperature and environmental conditions. If the temperature is too high, the material may lose its crystal water, so drying is usually carried out using hot water at 80 to 95°C. The drying process must also avoid exposure to CO₂, as the material can react with carbon dioxide and become unstable. For this reason, the drying system should operate in a sealed environment. Although the material has a loose structure, it doesn’t flow easily and tends to form crusts. The drying process must ensure even heat distribution, low energy consumption, and a clean working environment. Battery-grade LiOH•H₂O requires strict control over magnetic impurities, typically below 20 ppb. Additionally, exhaust treatment systems must be equipped to manage both dust and odor emissions effectively.

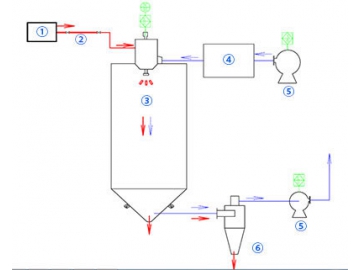

- To prevent lithium hydroxide monohydrate from reacting with CO₂ during drying, a sealed rotary tray dryer is used. An airlock is installed at the discharge outlet to reduce the risk of cold air being pulled in by the exhaust fan. The dryer’s internal structure is also specially designed to minimize the material’s contact with carbon dioxide throughout the process.

- Our rotary tray drying systems operate continuously with thermal efficiency reaching over 85%, making them suitable for stable and efficient production.

- Material loss is minimal, and over 99% of dust can be collected. This helps reduce waste and maintain a clean working environment.

- Each drying tray can be heated or cooled independently. Drying and cooling can be done within the same unit, with accurate control of product temperature.

- For materials containing small wet particles, a crushing mechanism is added inside the dryer to break clumps into fine powder. This improves heat transfer and ensures uniform drying.

- To meet the battery industry’s strict requirements on magnetic impurities (usually under 30 ppb), the parts in contact with the product can be made of titanium instead of stainless steel. This design has already been successfully implemented for several lithium material producers.

- A wet scrubber is used to remove dust and odors from the exhaust air, improving air quality and reducing emissions during operation.

- The dryer includes separate zones for drying and cooling within the same unit, with a physical barrier that prevents moisture from the drying section from moving into the cooling area. A specially designed opening allows smooth product flow without affecting performance.

- To address the poor flowability of lithium hydroxide monohydrate and its tendency to form crusts on the tray surface, a specially designed rake arm and rake blade structure is used to prevent material buildup and ensure smooth movement throughout the drying process.