Door Test

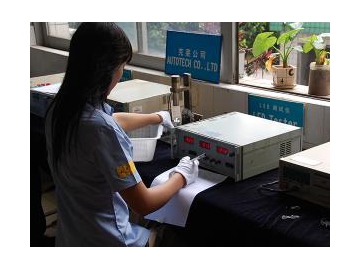

Fuda is a professional manufacturer of aluminum clad entry doors, stainless steel security doors, copper security doors, steel security doors, non-standard doors and other kinds of door products. Since our company is security oriented, we conduct shipment sampling tests to ensure the quality and performance of our doors.

Fuda will perform sample tests in batches. These tests include:Reliability test equipment: more than 500 opening and closing tests will be conducted on the door leaf. After the test, all parts will be tested for looseness, deformation, and damage.

Formaldehyde emission test equipment: it is used for the detection of formaldehyde content in adhesives, artificial board, etc.

Electrically heated thermostatic blast air dry oven: it is used to test the moisture content of products or for drying, heat treatment and other heating purposes.

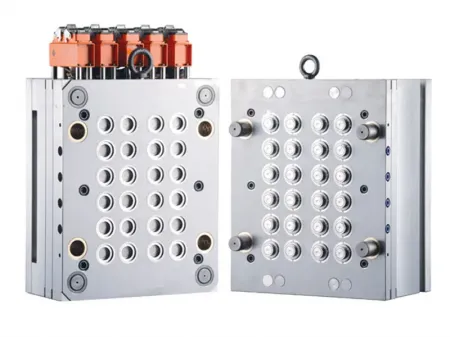

Bending and pressure resistance testing machine: it is used to test the flexural strength and compressive strength of the core plate.

Inspection platform: tests the distortion and bending of the door leaf.

Ultrasonic thickness gauge: it is used to measure the thickness of door materials according to the ultrasonic pulse reflection principle.

On the other side, Fuda will conduct targeted sampling tests on the safety performance of the doors regularly. Tests include: anti-pry test, anti-theft test, anti-collision test.

Situation 1: anti-pry test

Abstract: using Φ 40 steel pipe and Φ 20 crowbar, the door is not pried open in 20 minutes.

Situation 2: anti-theft test

Abstract: conduct security test by methods like drilling, cutting, saw, chisel, pry, pick, tear and others.

Situation 3: anti-collision test

Abstract: the beam of the hanger is connected with a 1500mm long rope, and a 30kg ball sandbag is used as a suspension which is used to test the anti-collision performance of the door.