Tire Repair Products

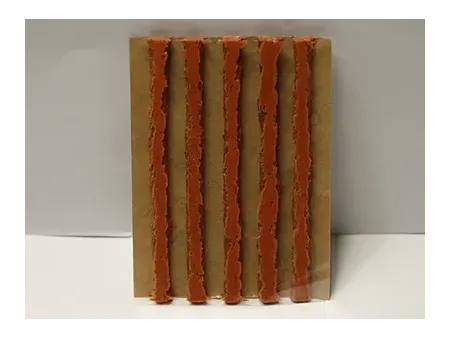

Our tubeless tire repair strings are produced using highly automated production lines developed in-house. The process involves impregnating polyester fibers with butyl rubber, followed by kneading, vulcanizing, and other production steps to ensure durability and performance. With nearly 20 years of experience in manufacturing, we can produce enough tire repair strings to serve 180,000 vehicles each day, making us a trusted supplier for over 220 brands across 25 countries.

- The tubeless tire repair strings provide a cost-effective solution, allowing users to perform tire repairs themselves, which significantly reduces both labor and material costs.

- They are versatile and can be used in various situations and environments, offering on-demand repair whenever needed.

- The repair process is simple and efficient, as there is no need to remove the tire from the wheel rim, enabling easy tire restoration.

- We offer tailored solutions based on different tire types, environments, and repair size requirements, ensuring the right fit for your specific needs.

| Size | Recommended Applications | Packaging |

| 100×4mm | Bicycle tires; Motorcycle tires | 5 strings per sheet; 6 sheets per box; 120 boxes per carton |

| 100×5mm | Passenger car tires; SUV tires; Agricultural vehicle tires | 5 strings per sheet; 6 sheets per box; 120 boxes per carton |

| 100×6mm | Light-duty truck tires; Heavy-duty truck tires; Off-road vehicle tires | 5 strings per sheet; 6 sheets per box; 120 boxes per carton |

| 200×4mm | Bicycle tires; Motorcycle tires | 5 strings per sheet; 6 sheets per box; 60 boxes per carton |

| 200×5mm | Passenger car tires; SUV tires; Agricultural vehicle tires | 5 strings per sheet; 6 sheets per box; 60 boxes per carton |

| 200×6mm | Light-duty truck tires; Heavy-duty truck tires; Off-road vehicle tires | 5 strings per sheet; 6 sheets per box; 60 boxes per carton |

Note: Special specifications are customizable

MOQ: 50 cartons of tubeless tire repair strings

Repairing a flat tire is easy with our tire repair strings. Follow these 5 simple steps for a quick, complete and effective repair, allowing you to restore the tire without needing specialized equipment.

We offer comprehensive customization options to meet your specific needs. This includes customizing the logo printed on the backing paper of the tire repair strings, as well as printing your logo on the plastic packaging bags and designing the color scheme and logo for the packaging boxes. Most importantly, we can tailor the softness, adhesion, and color of the tire repair strings according to your requirements. Additionally, we are able to provide samples for testing, ensuring that the final product meets your exact specifications before proceeding with bulk orders.

Trust us to meet your unique customization needs. With our expertise and attention to detail, we are committed to delivering high-quality, tailor-made tire repair solutions that align with your specific requirements.

The minimum order quantity is 50 cartons.

Customization services are available for orders of 100 cartons or more.