Our IBC Tank Blow Molding Machine is specifically designed for the production of high-quality IBC bottle liners. With its adaptable setups and flexible production capacities, this cutting-edge technology meets a wide range of customer needs.

Features:

- Versatile Capacity Options: Supports production of IBC liners with capacities of 500L, 800L, 1000L, and 1200L.

- Customizable Layers: Choose from single-layer, double-layer, or triple-layer blow molding configurations.

- Precision Engineering: Ensures durable and uniform bottle liners, meeting the highest industry standards.

- High Efficiency: Optimized for rapid production cycles and consistent quality output

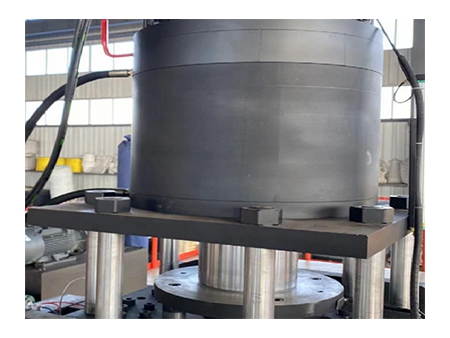

Die Head

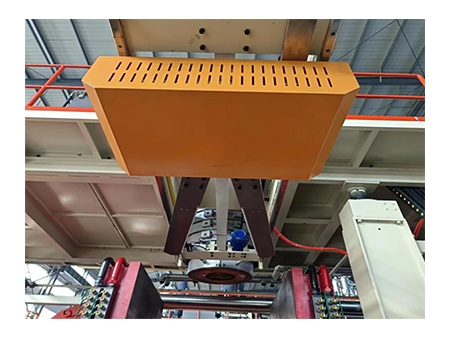

Die Head Touch Screen

Touch Screen Linear Guideway

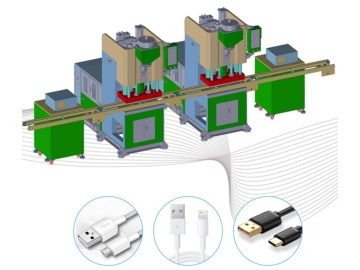

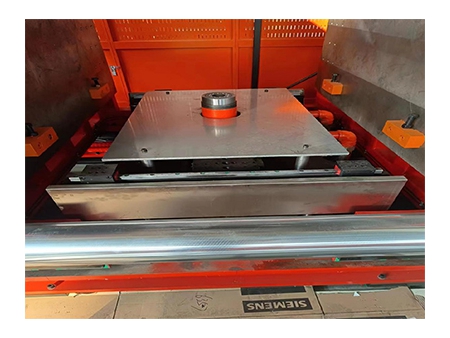

Linear Guideway Manipulator

Manipulator Integrated Loading System

Integrated Loading System Downward Blow Station

Downward Blow Station

Specifications

| Number of Layers | |||

| Extrusion System (Diameter) | 150mm | 120mm×2 | 120mm×1 110mm×2 |

| Drive Power | 160kw | 110kw×2 | 110kW×1 90kW×2 |

| Max. Extrusion Capacity | 400kg/hr | 600kg/hr | 700kg/hr |

| Clamping Force | 2000kN | ||

| Die Head | 600mm | ||

| Dimensions (L×W×H) | 5×6.5×7m | 5.10×6.5×7m | 11.85×5.6×7.2m |

| Weight | 60 tons | 65 tons | 70 tons |

| Functions | Germany PWDS die head, optional function for wall thickness control | ||

| Control System | Japan MOOG wall thickness control system, Siemens PLC | ||

| Machine Speed | Standard: 600 tanks/day High speed: 720 tanks/day | ||