Ampoule/Vial Leak Testing Machine

AJLL Container Closure Integrity Testing (CCIT)

- Speed: 200-600pcs/min

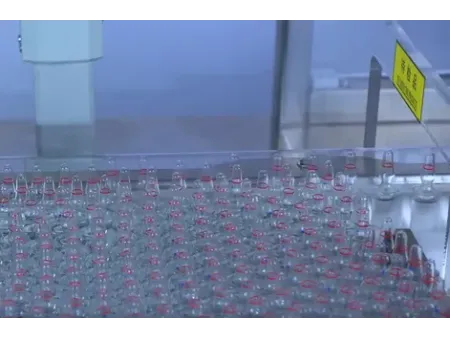

- Applicable container: 1-20ml ampoules, vials and oral liquid bottles

- Power supply: 2.4kW, 380V 50Hz (4-output high-frequency high-voltage power supply)

- Output voltage: 10-35kV

- Output frequency: 500Hz-50kHz

- Machine dimensions (L×W×H): 3694×1180×1364mm

- Machine weight: approx. 1000kg

- Inspection speed: 200–600 bottles per minute

- Supports ampoules and vials from 1ml to 20ml

- Applies HVLD technology to detect micro-leaks without contact or contamination

- Built with components from internationally recognized brands, including Mitsubishi servo motors

- Fully compliant with FDA 21 CFR Part 11 standards

- Equipped with a user-friendly HMI for tracking operations, parameter changes, and production records

Used to inspect ampoules, vials, and oral liquid bottles for potential leakage. It accurately detects micro-holes and cracks located in critical areas such as the seal, body, and bottom of the container, ensuring that each unit meets container closure integrity standards before release.

- Designed for both standalone operation and integration into continuous production lines, this leak detection solution performs automated inspections on each container without interrupting the flow.

- Detects microcracks and pinholes that are often undetectable with conventional methods, ensuring precise and consistent results across all units tested.

- The inspection process uses low-energy high-voltage signals applied over a short duration. Containers remain insulated during testing, preventing any impact on the liquid contents and maintaining product integrity.

- Non-contact electrodes eliminate any possibility of product contamination, making the process safe for both the drug and the end user.

- One single unit can be adapted to multiple container types by simply replacing the format parts. It's suitable for ampoules, vials, and oral liquid bottles, increasing overall equipment efficiency.

- Equipped with a responsive touchscreen interface that supports real-time monitoring, control, data collection, and print-ready documentation for traceability.

- Includes complete validation documentation to support GMP compliance and regulatory audits.

- Developed using proprietary technologies, with 17 officially registered patents covering both invention and utility models granted by the Chinese National Intellectual Property Administration.

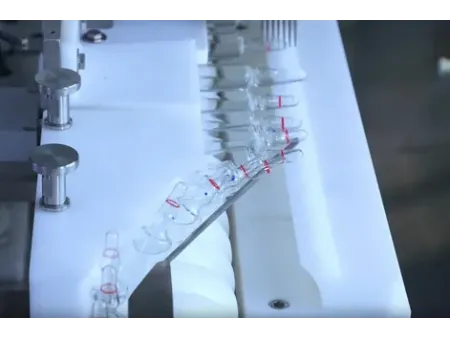

Containers are first fed onto the infeed conveyor, where they are evenly spaced by a star-wheel mechanism. From there, a guiding track directs each unit toward a screw feeder, which rotates the container by 90 degrees into a horizontal position. Once aligned, each container passes through a series of inspection stations, with each station focusing on specific areas depending on the inspection requirements. After testing, containers are automatically sorted: accepted units continue down the production line, while those that fail the inspection are separated by a rejection mechanism for further handling.

High Voltage Leak Detection is used to identify micro-defects in ampoules and vials without breaking or opening the container. The method applies a high-frequency electrical signal through a pair of electrodes positioned on opposite sides of the glass. Because the container acts as an insulator, a capacitive circuit is formed between the electrodes and the liquid product inside.

When the container is intact, the insulating wall prevents direct contact, and only a very low current flows through the system (I1). However, if there’s a crack, pinhole, or seal failure, the conductive solution makes direct contact with the electrodes, allowing a higher current to pass (I2). This sudden change in current flow is precisely what signals the presence of a leak. By continuously monitoring and comparing current levels, the machine can detect even the smallest structural defects, ensuring that each unit meets strict container closure integrity requirements.

What is High Voltage Leak Detection (HVLD)?

HVLD is a non-destructive testing method that uses the conductivity of liquid products sealed inside non-conductive containers. A high-frequency, high-voltage signal is applied through external electrodes, and the system monitors changes in discharge current to determine if there is a leak.

What are the advantages of HVLD in pharmaceutical applications?

Unlike traditional methods like vacuum decay or dye immersion, HVLD offers several benefits:

- Detects extremely small pinholes or cracks

- Non-destructive and free from cross-contamination

- Enables 100% inline inspection at high speeds

- Supports growing demand for precise CCIT in pharmaceutical packaging

Can ampoule/vial testers perform non-destructive inspections?

Yes. The test applies minimal energy over a short duration. During inspection, properly sealed containers remain electrically insulated, so the liquid content is not affected, and product integrity is preserved.

How does HVLD contribute to cost savings in production?

This method reduces reliance on manual visual inspection, minimizes the risk of discarding good products due to destructive testing, and allows early detection of defects, helping to prevent costly batch recalls.